Flexible light bar capable of synchronously displaying material information

A flexible light strip and information synchronization technology, which is applied in logistics, lighting and heating equipment, lighting device components, etc., can solve the problems of large warehouse space waste, small material occupation, error-prone, etc., to improve storage density, The installation is convenient and stable, and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

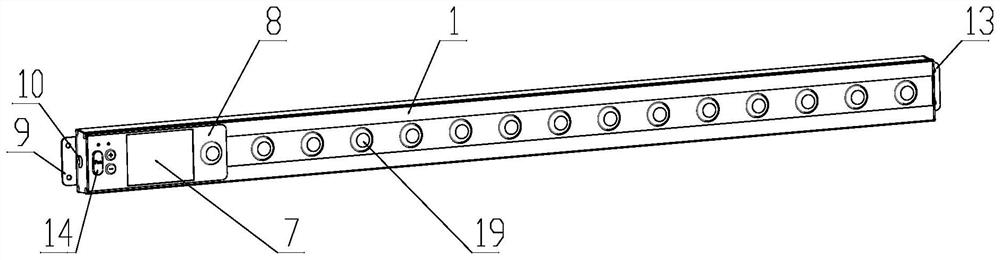

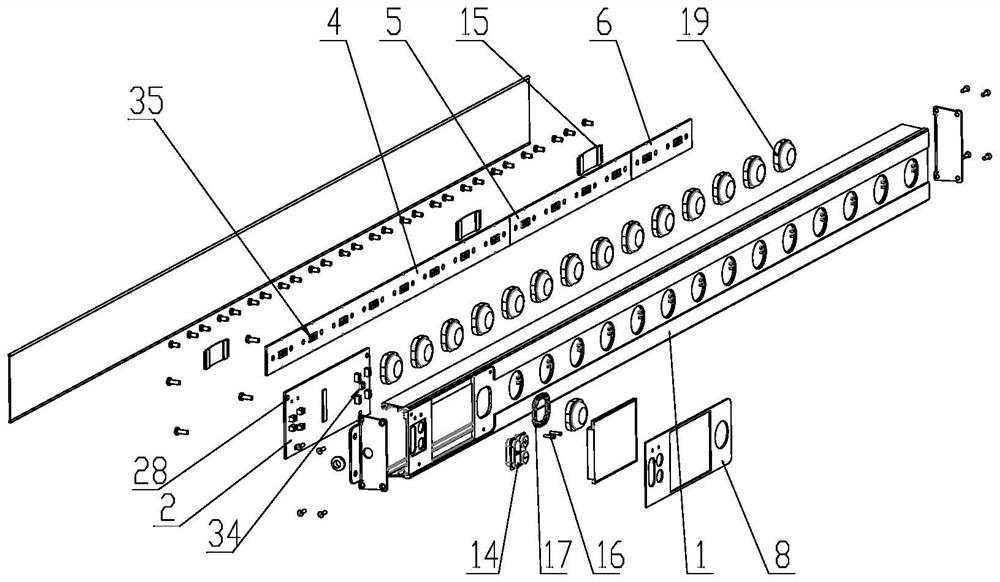

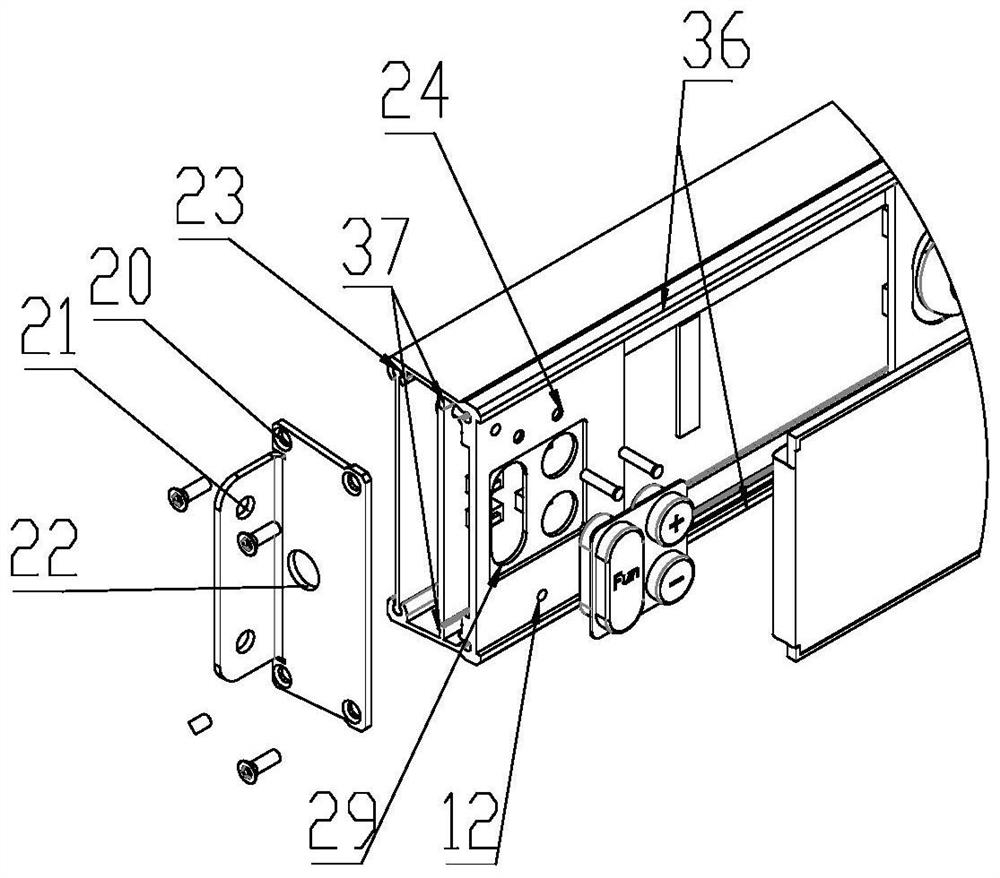

[0023] like figure 1 , 2 , 3, 4, and 5, a flexible light bar with synchronous display of material information, including a control system and a flexible light bar body, the flexible light bar body includes a housing 1, a main board 2, a back cover plate 3, From the first plate 4, the second plate 5, the third plate 6, the left end cover 9 and the right end cover 13, the upper and lower sides of the surface of the casing 1 are provided with trapezoidal prisms 36, and the left and right sides of the surface of the casing 1 are adjacent A concave surface 1 33 and a concave surface 2 30 are provided, and the surface of the concave surface 1 33 is provided with a film 8, and the housing 1 is provided with two rectangular prisms 37 for limiting the position of the main board 2, one for the slave board 1 4, The U-shaped groove 11 for positioning from the second plate 5 and the third plate 6 and the two sliding grooves 23 for docking with the back sealing plate 3, the main board 2 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com