BIPV photovoltaic module and preparation method thereof

A technology for photovoltaic modules and installation panels, applied in chemical instruments and methods, electrical components, semiconductor devices, etc., can solve the problems of hidden dangers of waterproofing, complicated installation operations, and high engineering costs, and achieve the effect of solving complex installations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

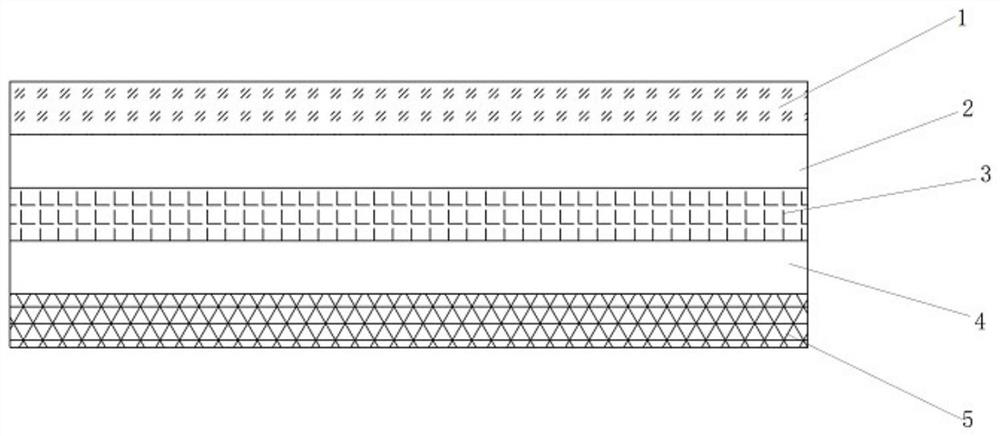

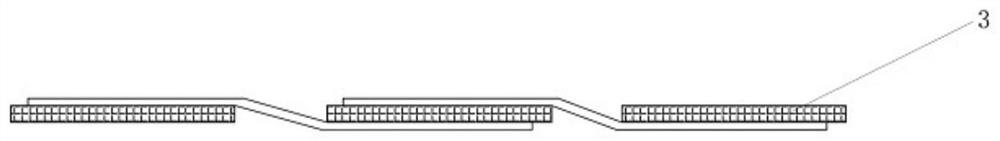

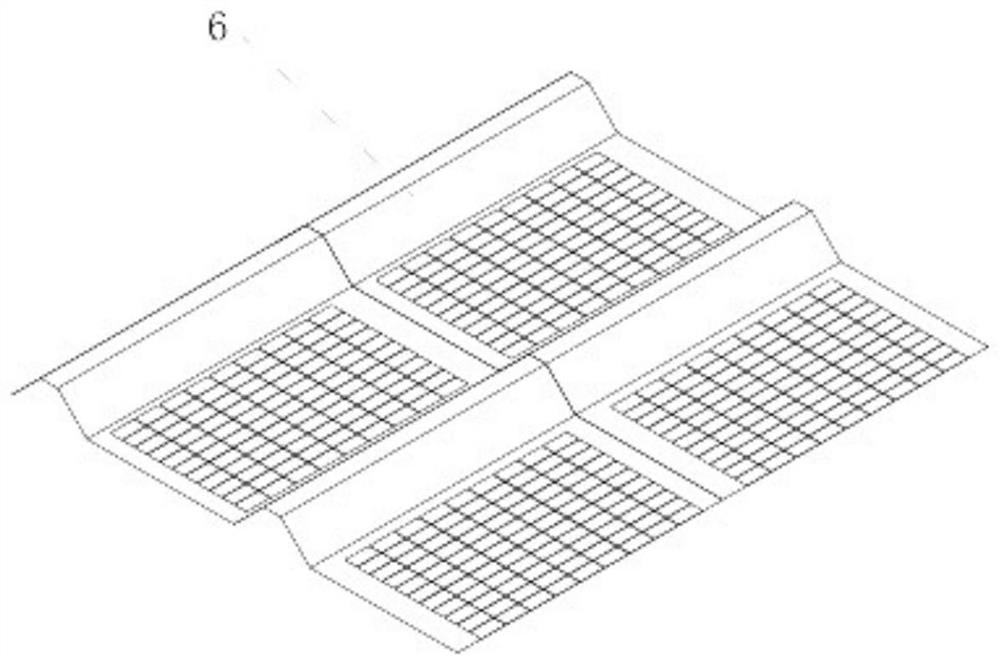

[0026] like Figure 1-3 As shown, this embodiment provides a BIPV photovoltaic module, which includes a transparent organic polymer fluorine film 1, an encapsulation adhesive film 2, a battery string 3, an insulating adhesive film 4 and an installation panel 5 that are stacked in sequence, wherein the installation panel 5 adopts Color-coated steel plate 6.

[0027] Specifically, the transparent organic polymer fluorine film 1 is a fluorine-containing film with a thickness of 250-400 μm, a light transmittance greater than 85%, and a hydrophobic coating on the outer surface.

[0028] Specifically, the encapsulation film 2 is selected from one of EVA (copolymer of ethylene and vinyl acetate), POE (polyolefin), and PVB (polyvinyl butyral ester). The transparent organic polymer fluorine film 1, the battery string 3, the insulating film 4 and the color-coated steel plate 6 are laminated and integrally formed by the laminator heating and vacuuming.

[0029] Preferably, the battery ...

Embodiment 2

[0034] like figure 1 , 2 As shown in and 4, this embodiment provides a BIPV photovoltaic module, which includes a transparent organic polymer fluorine film 1, an encapsulation adhesive film 2, a battery string 3, an insulating adhesive film 4 and an installation panel 5, which are stacked in sequence. The panel 5 adopts a waterproof membrane 7 .

[0035] Specifically, the transparent organic polymer fluorine film 1 is a fluorine-containing film with a thickness of 250-400 μm, a light transmittance greater than 85%, and a hydrophobic coating on the outer surface.

[0036] Specifically, the encapsulation film 2 is selected from one of EVA (copolymer of ethylene and vinyl acetate), POE (polyolefin), and PVB (polyvinyl butyral ester). The transparent organic polymer fluorine film 1, the battery string 3, the insulating film 4 and the color-coated steel plate 6 are laminated and integrally formed by the laminator heating and vacuuming.

[0037] Preferably, the battery string 3 s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com