Processing method of seamless internally-attached cup lady underwear and underwear thereof

A technology for women's underwear and a processing method, which is applied to devices for pulling clothes, bras, bras, etc., can solve the problems of affecting comfort, low processing efficiency, poor finished product comfort, etc., so as to reduce sewing steps and improve processing efficiency. , the effect of high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

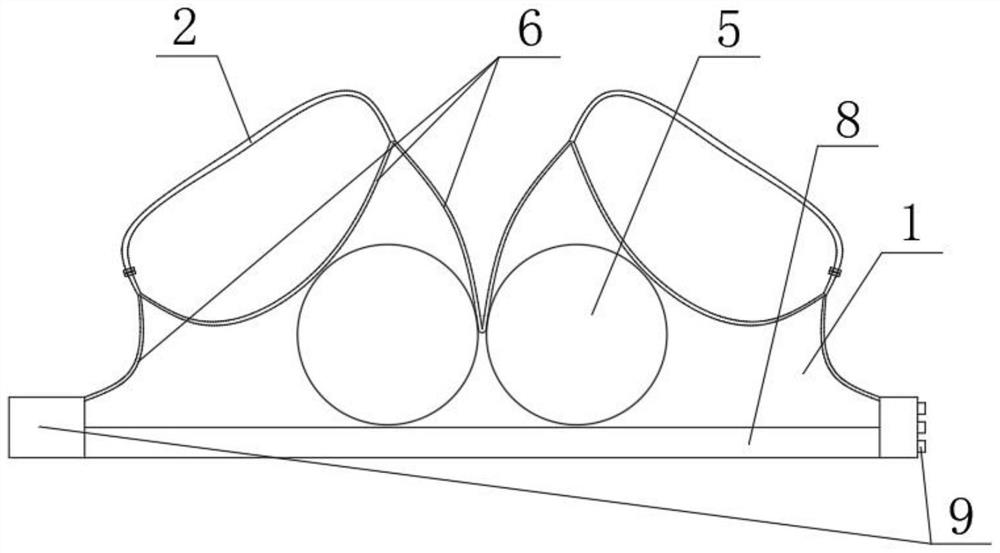

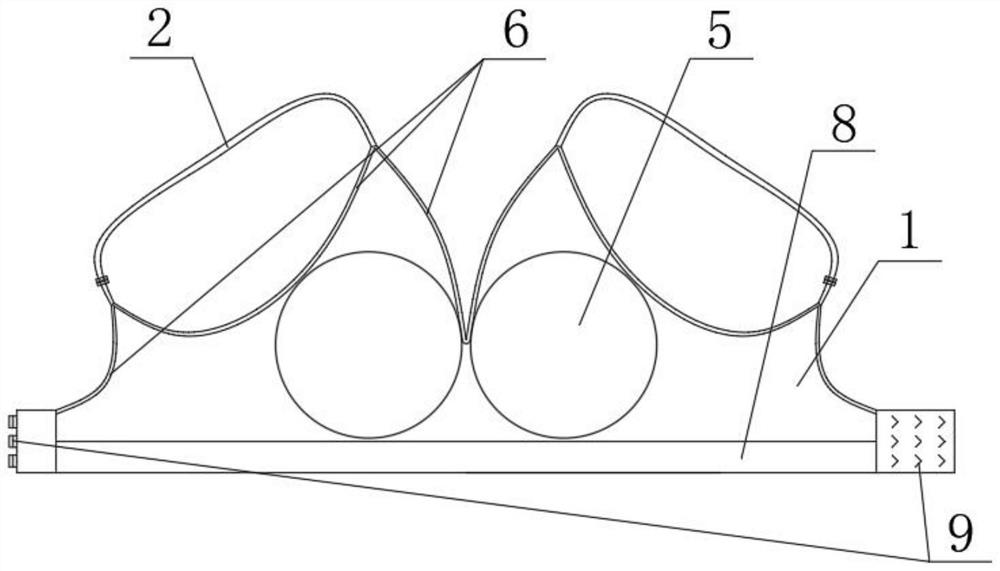

[0033] Example 1. A processing method for seamless inner cup ladies underwear, comprising the following steps:

[0034] a. Weaving an integrated outer sheet and inner sheet through a seamless knitting machine;

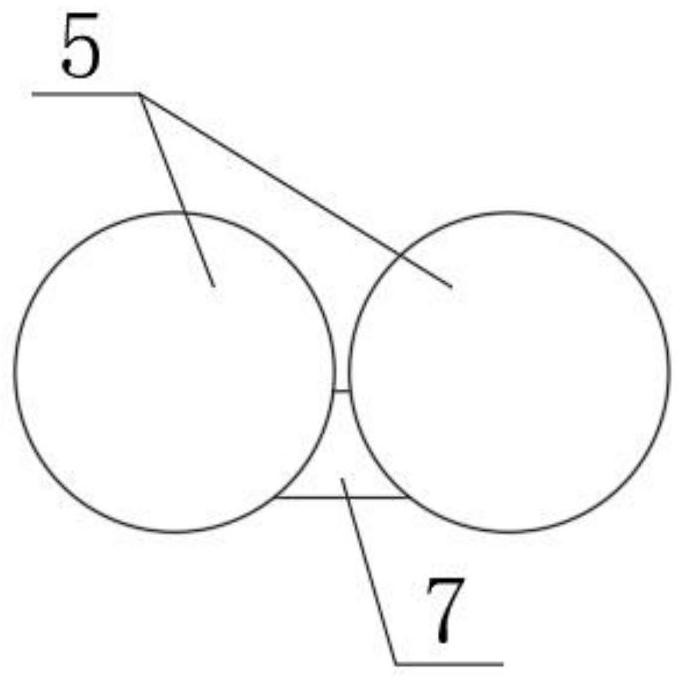

[0035] b. Prepare two three-dimensional mold cups corresponding to the chest on the left and right sides, and connect the setting yarn between the two three-dimensional mold cups;

[0036] c. Hot-melt adhesives are arranged on the inner surfaces of the shaping yarn and the two three-dimensional mold cups;

[0037] d. Place the outer sheet on the hot-pressing mold for hot-pressing and shaping, so that the position of the outer sheet corresponding to the chest on both sides forms the same three-dimensional convex shape as the two mold cups;

[0038] e. Remove the outer sheet, then place the inner sheet on the hot pressing mold, and place the side with the hot melt adhesive on the two three-dimensional mold cups and the setting yarn facing the inner sheet, and make the ...

Embodiment 2

[0045] Example 2. A processing method of seamless inner cup women's underwear, comprising the following steps:

[0046] a. Weaving an integrated outer sheet and inner sheet through a seamless knitting machine;

[0047] b. Prepare two three-dimensional mold cups corresponding to the chest on the left and right sides, and connect the setting yarn between the two three-dimensional mold cups;

[0048] c. A hot-melt adhesive is arranged on both the setting yarn and the inner sides of the two three-dimensional mold cups;

[0049] d. Place the outer sheet on the hot-pressing mold for hot-pressing and shaping, so that the positions on the outer sheet corresponding to the breasts on both sides form the same three-dimensional convex shape as the two mold cups;

[0050] e. Remove the outer sheet, then place the inner sheet on the hot pressing mold, and place the side with the hot melt adhesive on the two three-dimensional mold cups and the setting yarn facing the inner sheet, and make ...

Embodiment 3

[0057] Example 3. A processing method of seamless inner cup women's underwear, comprising the following steps:

[0058] a. Weaving an integrated outer sheet and inner sheet through a seamless knitting machine;

[0059] b. Prepare two three-dimensional mold cups corresponding to the chest on the left and right sides, and connect the setting yarn between the two three-dimensional mold cups;

[0060] c. A hot-melt adhesive is arranged on both the setting yarn and the inner sides of the two three-dimensional mold cups;

[0061] d. Place the outer sheet on the hot-pressing mold for hot-pressing and shaping, so that the positions on the outer sheet corresponding to the breasts on both sides form the same three-dimensional convex shape as the two mold cups;

[0062] e. Remove the outer sheet, then place the inner sheet on the hot pressing mold, and place the side with the hot melt adhesive on the two three-dimensional mold cups and the setting yarn facing the inner sheet, and make ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com