Spraying supporting device for square inner pot product

A support device and inner pot technology, applied in the direction of spraying device, etc., can solve the problems such as the risk of paint falling off, high product defect rate, low production efficiency, etc., and achieve the goal of reducing spraying process, reducing processing technology and improving production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

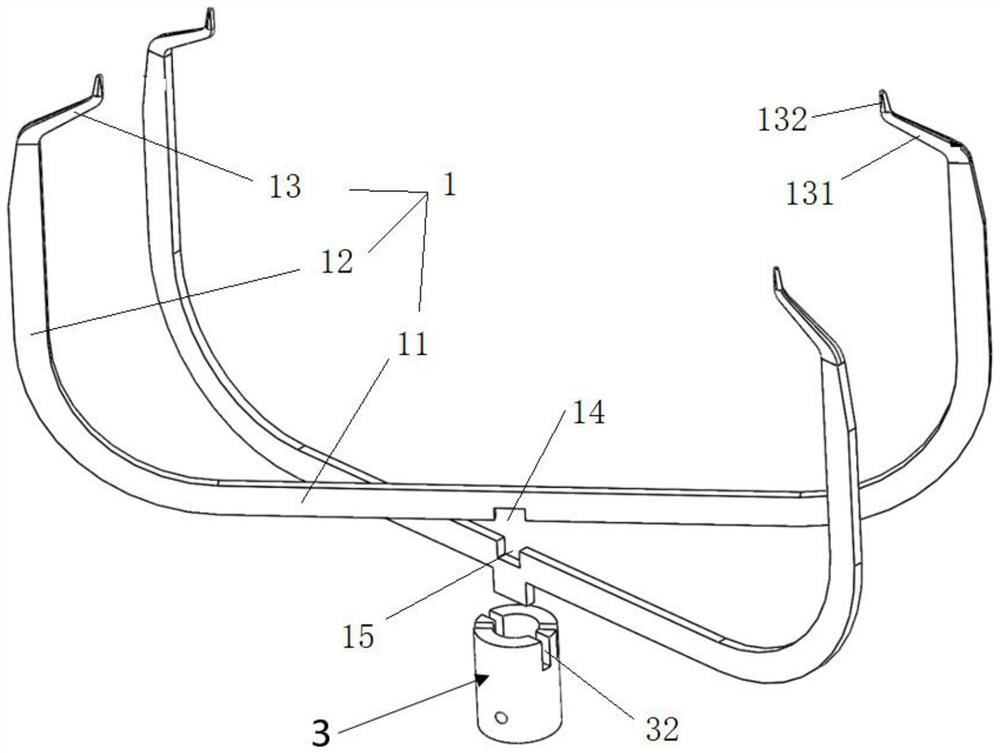

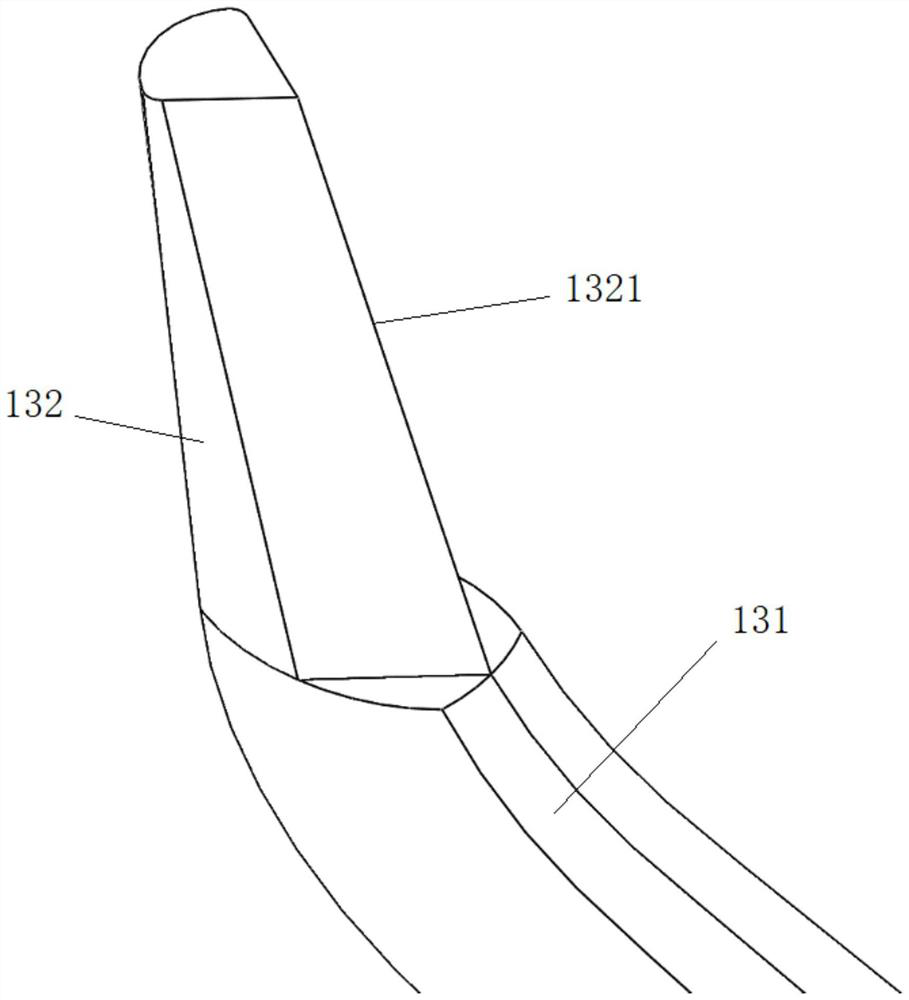

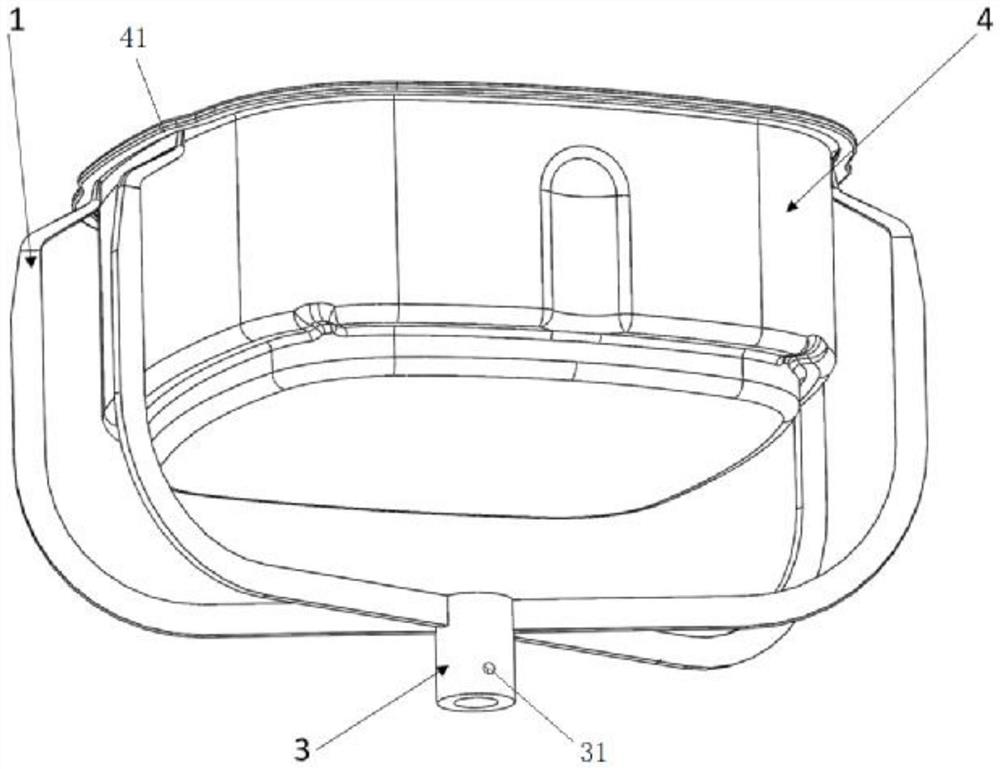

[0021] combine Figure 1 to Figure 4 The inner pot product spraying support device of the present invention will be further described.

[0022] An inner pot product spraying support device is characterized in that it comprises a connecting head 3 and a support rod group. The connecting head 3 is a tubular structure, and there is a lateral positioning rod 31 in the connecting head 3, and the connecting head 3 cooperates with the circumferential limit of the runner through the lateral positioning rod to realize the circumferential rotation of the connecting head 3; There is a positioning groove 32 on the upper end of the . The support rod group includes two support rods 1 , each of the support rods 1 includes a bottom wall 11 and a support arm 12 formed by upwardly bending two sides of the bottom wall 11 , and the bottom walls 11 of the two support rods 1 cross. The connection forms an X-shaped structure, and at the same time, it is inserted and fixed in the two positioning gr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap