Yarn tension adjusting device and spinning equipment

A technology for adjusting device and yarn tension, which is applied in the field of yarn tension adjusting device and textile equipment, which can solve problems such as adverse effects of yarn conveying stability, adverse effects of production, and yarn jumping, so as to prevent yarn breakage or jumping , Improve production efficiency and avoid breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

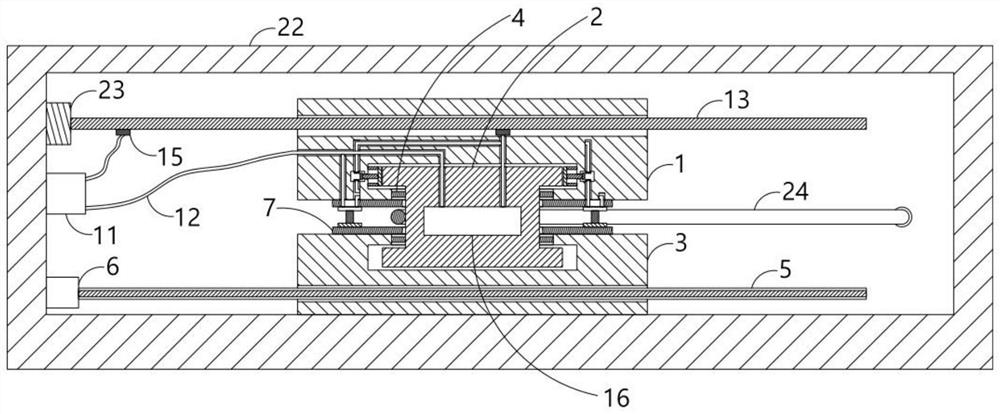

Embodiment 1

[0036] A yarn tension adjustment device includes an adjustment mechanism driven by an adjustment motor 6 to slide, the yarn 24 slides through the adjustment mechanism during the conveying process, and the adjustment motor 6 drives the adjustment mechanism to slide according to the tension of the yarn 24 during the conveying process. , so as to tighten or relax the yarn 24 to realize the adjustment of the tension of the yarn 24. The adjustment mechanism includes a first cover plate 1, an adjustment wheel 2, a second cover plate 3 and a control circuit. The adjustment wheel 2 is wide at both ends and a middle part. Narrow I-shaped structure, the adjustment wheel 2 of the I-shaped structure is convenient for both ends of the adjustment wheel 2 to extend into the first cover plate 1 and the second cover plate 3, and the two ends of the adjustment wheel 2 are respectively movable into the first cover plate. 1. In the second cover plate 3, the yarn 24 slides through the adjustment wh...

Embodiment 2

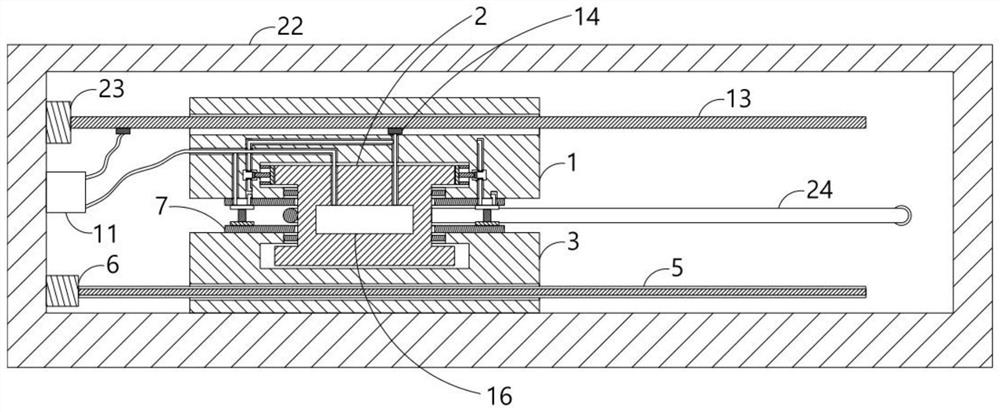

[0045] The second embodiment provides a way of adjusting the motor 6 to drive the adjusting mechanism to slide on the basis of the first embodiment, that is: the tension signal receiver is installed in the adjusting motor 6, and the tension signal receiver receives the tension of the yarn 24 in real time, and according to The difference between the actual tension of the yarn 24 and the suitable tension drives the adjustment motor 6 to work, and the output end of the adjustment motor 6 is installed with a threaded screw 5, and the second cover plate 3 is provided with an inner thread that cooperates with the threaded screw 5. The threaded groove, the adjusting motor 6 drives the threaded screw 5 to rotate, and drives the second cover 3 to slide through the threaded transmission between the threaded screw 5 and the second cover 3, and the second cover 3 slides to drive the adjustment wheel 2 to slide together. The wheel 2 slides to adjust the tension of the yarn 24. The thread dr...

Embodiment 3

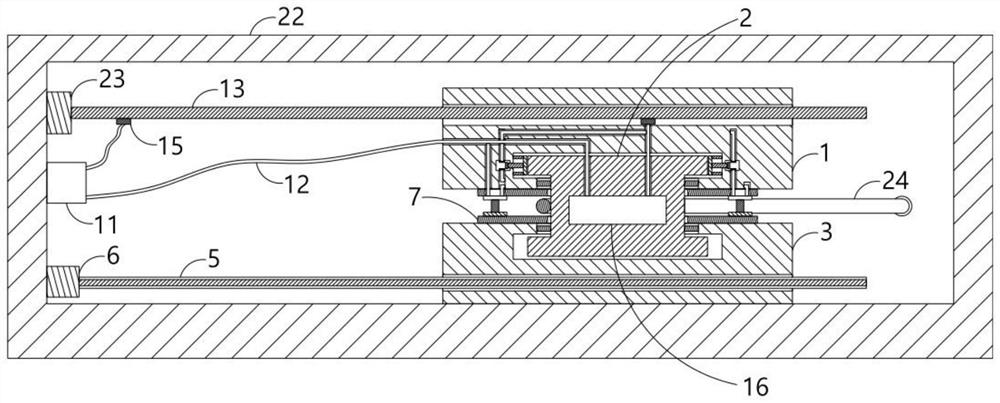

[0047] The third embodiment discloses the specific structure of the trigger switch on the basis of the first embodiment, that is, the trigger switch includes a push plate 17 and a push rod 19 fixedly connected to one end of the push plate 17 away from the adjustment wheel 2, and the push plate 17 is connected to the first end of the push plate 17. An elastic connecting rod 18 is fixedly connected between the inner walls of the cover plate 1 , a power receiving rod 20 is fixedly connected to the end of the push rod 19 away from the push plate 17 , and the wire 12 is electrically connected with two power connecting rods that are electrically connected to the power receiving rod 20 . Plate 21, the first cover plate 1 is provided with a trigger switch cavity 101, the push rod 19 slides into the trigger switch cavity 101, the power receiving rod 20 and the two power receiving plates 21 are located in the trigger switch cavity 101, and the two power The plates 21 are arranged at inte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com