Noise reduction system and noise reduction method for double-drum vibratory roller and vibratory roller

A technology of vibratory roller and noise reduction system, which is applied in the direction of roads, roads, road repairs, etc., can solve the problem of high noise in the cab, and achieve the effect of solving excessive noise and reducing huge noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

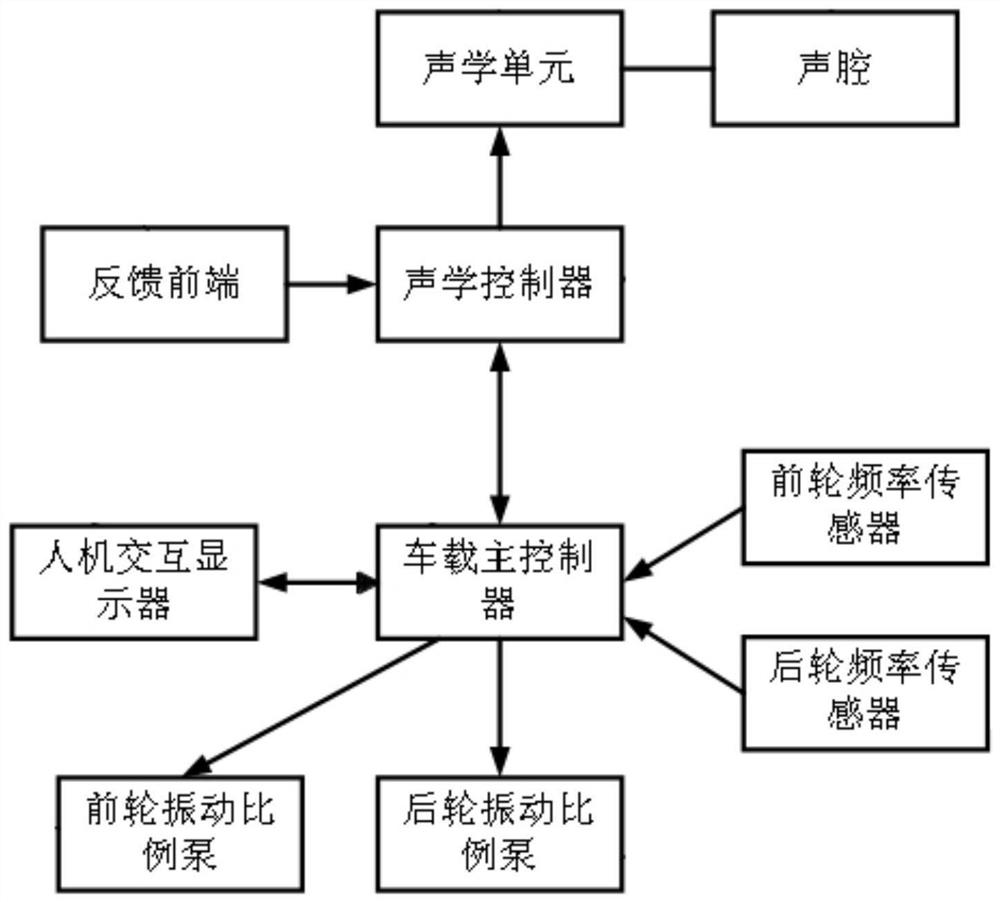

[0033] A noise reduction system for a double-drum vibratory roller, comprising a vehicle-mounted main controller 1, an acoustic controller 2, an acoustic unit 3, a feedback front end 4 and a human-computer interaction display 5;

[0034] The on-board main controller 1 includes a processor and a storage medium, and the storage medium is used to store the current value corresponding to the vibration frequency of the drum. The data exchange terminal of the on-board main controller 1 is respectively connected to the acoustic controller 2 and the human-computer interaction display 5 through the bus. , the human-computer interaction display 5 is installed in the cab of the vibratory roller, and people can input control instructions to the vehicle-mounted main controller 1 through the human-computer interaction display 5, and the human-computer interaction display 5 can display the output content of the vehicle-mounted main controller 1;

[0035] The vehicle-mounted main controller 1 ...

Embodiment 2

[0040] A noise reduction method for a double-drum vibratory road roller, comprising the following steps:

[0041] A. Press the button to automatically calibrate the vibration frequency of the drum of the vibratory roller to adjust the vibration frequency difference between the two drums;

[0042] B. Since the double-drum vibratory road roller has two working states of double-drum vibration and single-drum vibration, and the two working states are activated by the operator in the cab through the key board, and open on the human-computer interaction display 5 After the active noise reduction button is pressed, the main vehicle controller 1 judges that the current is two-wheel vibration and then jumps to step E, and if it is single-wheel vibration, it is executed sequentially;

[0043] C. The main vehicle controller 1 reads the vibration frequency of the corresponding steel wheel, and transmits the real-time vibration frequency to the acoustic controller 2. The acoustic controlle...

Embodiment 3

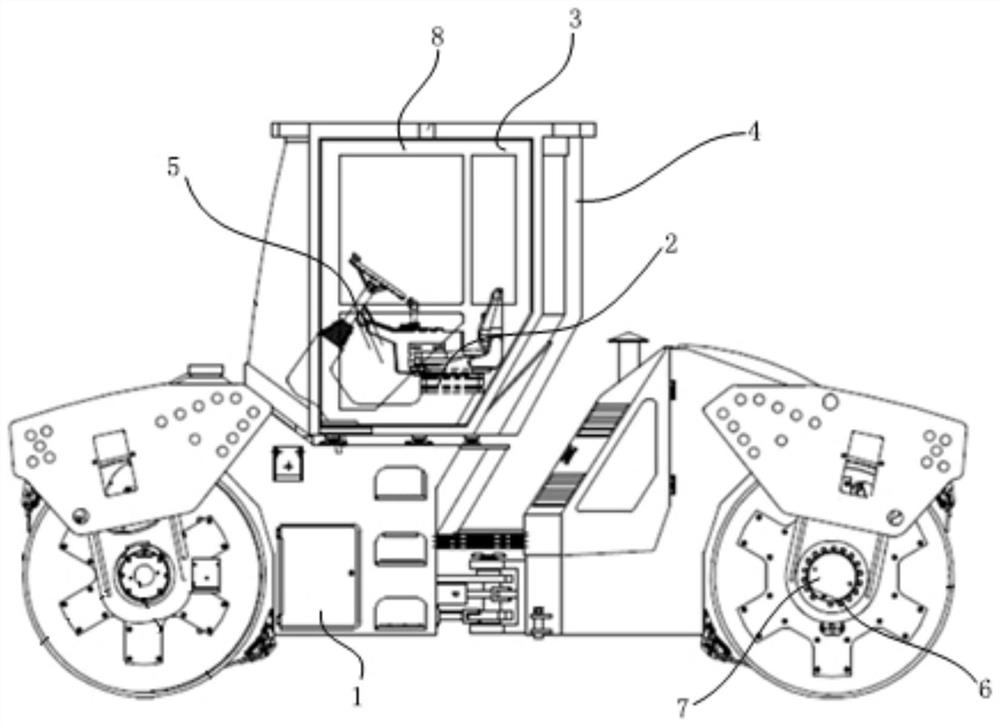

[0048] A vibratory road roller includes the above-mentioned noise reduction system for the double-drum vibratory road roller.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com