Method for installing fan on three-leg platform ship

A platform and wind turbine technology, applied in the field of offshore wind turbine installation, can solve the problems of high technical difficulty, resource scarcity and installation cost, etc., and achieve the effect of alleviating resource scarcity, not easy to ship collision, and large moving range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

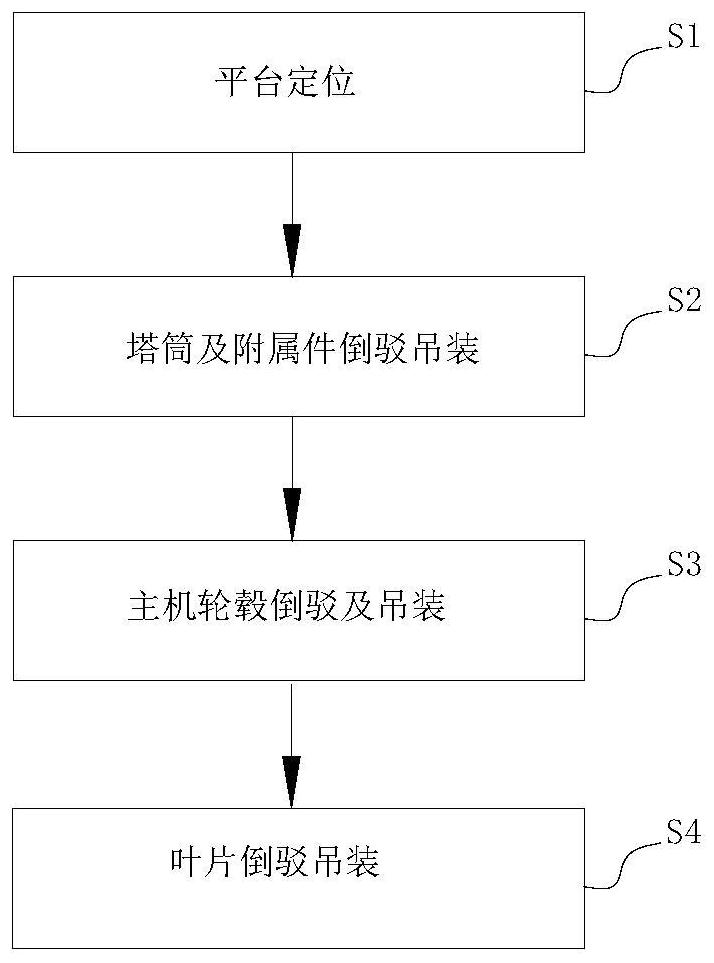

[0032] Embodiment: This embodiment provides a method for installing a fan on a three-legged platform ship, as shown in the attached figure 1 shown, follow the steps below:

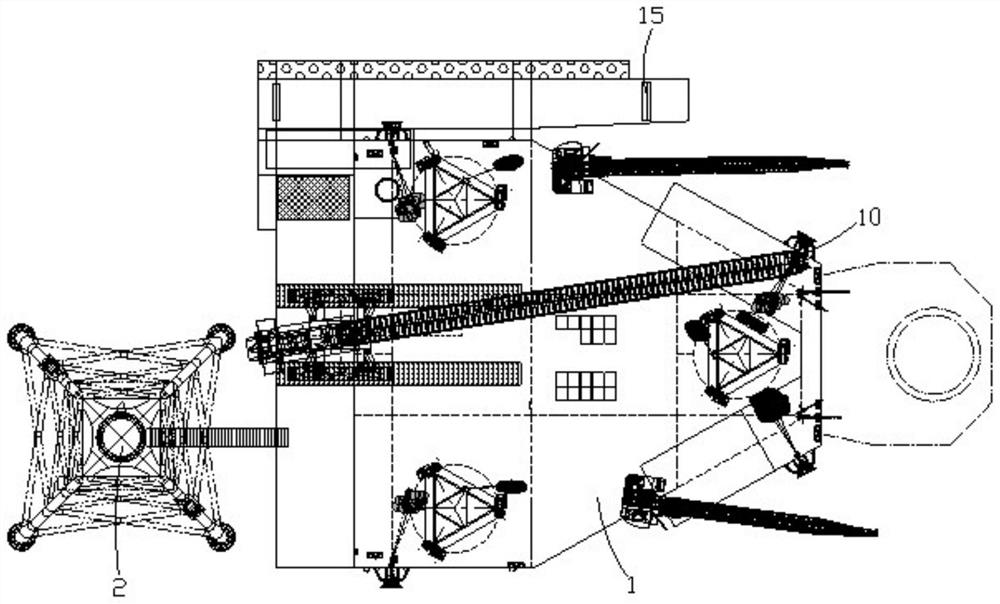

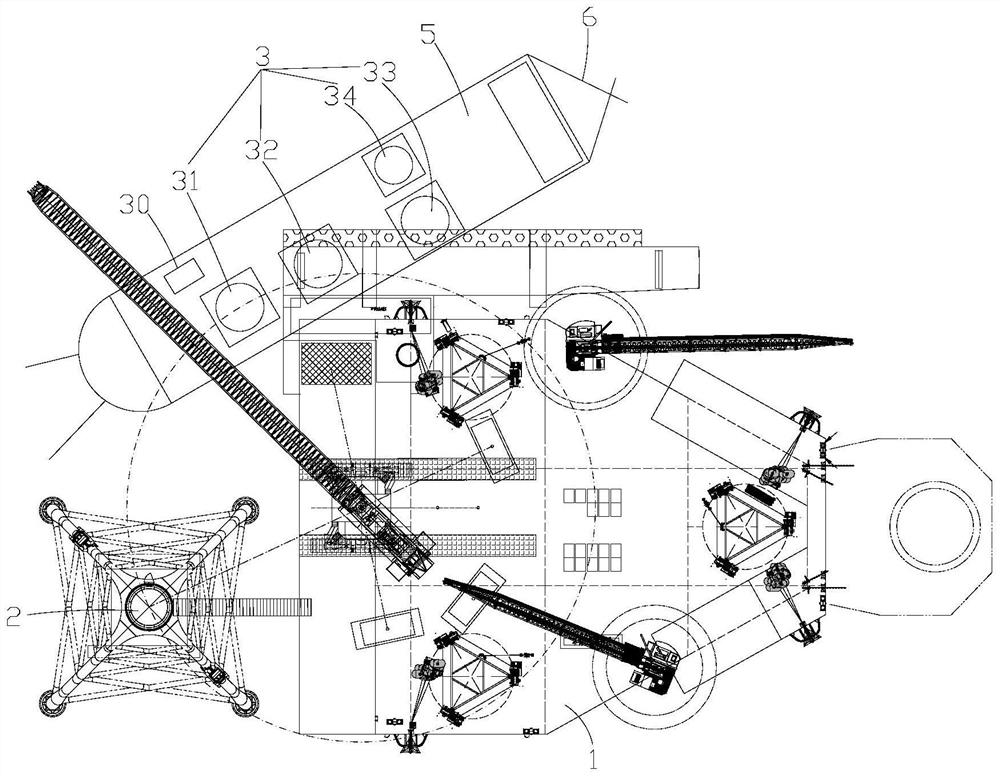

[0033] S1. Platform positioning: as attached figure 2 As shown in the figure, the present invention uses a three-legged platform vessel 1 to install the wind turbine. The three-legged platform vessel 1 is provided with a tower hanger 10. When the three-legged platform vessel 1 arrives at the operating wind field, the three-legged platform vessel 1 is moved by a digital positioning system. Preliminary positioning is carried out, and according to the positioning results, the three-legged platform ship 1 is dropped at the anchor position in the downstream direction, and moved to the vicinity of the construction position through the anchor, the construction position is the position of the engineering pile, and the three-legged platform ship The bow and stern of 1 can precisely adjust the position of the thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com