Full-ring stamping combustion test air inlet platform cooled through natural air entraining

A technology of combustion test and ram combustion chamber, which is applied in the direction of engine test, jet engine test, gas turbine engine test, etc., to achieve the effect of protection, heat radiation reduction and economical cooling method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

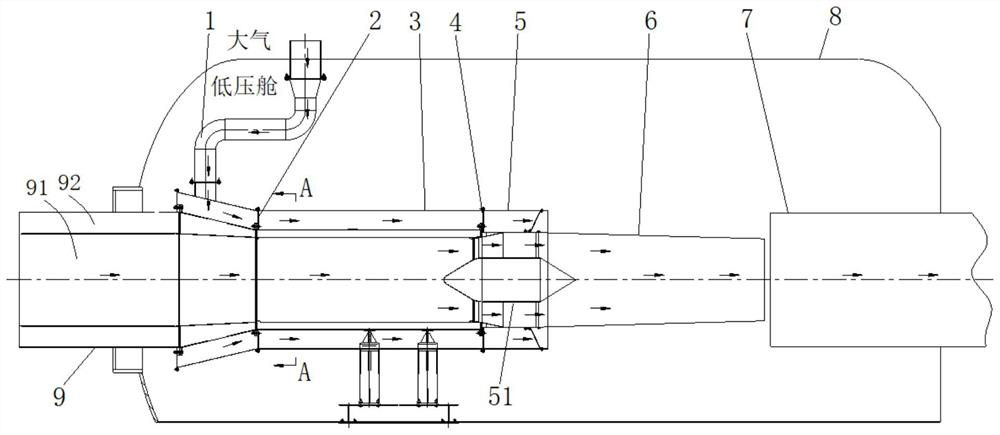

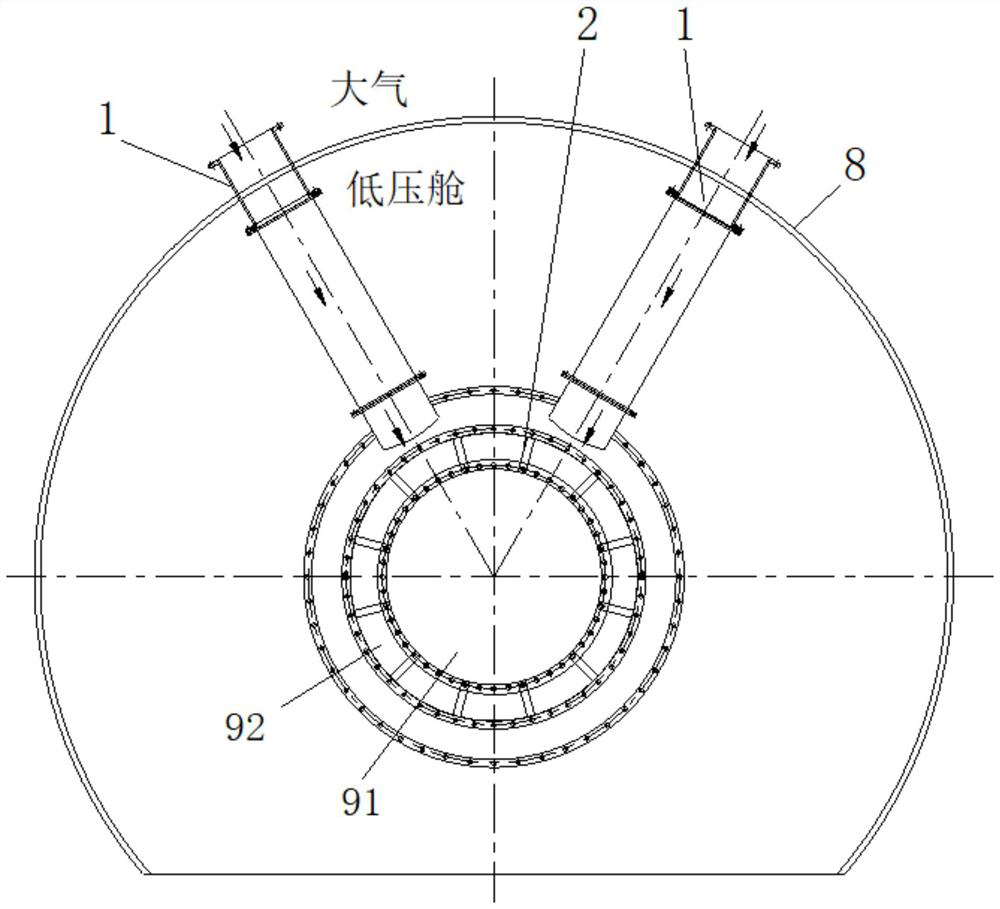

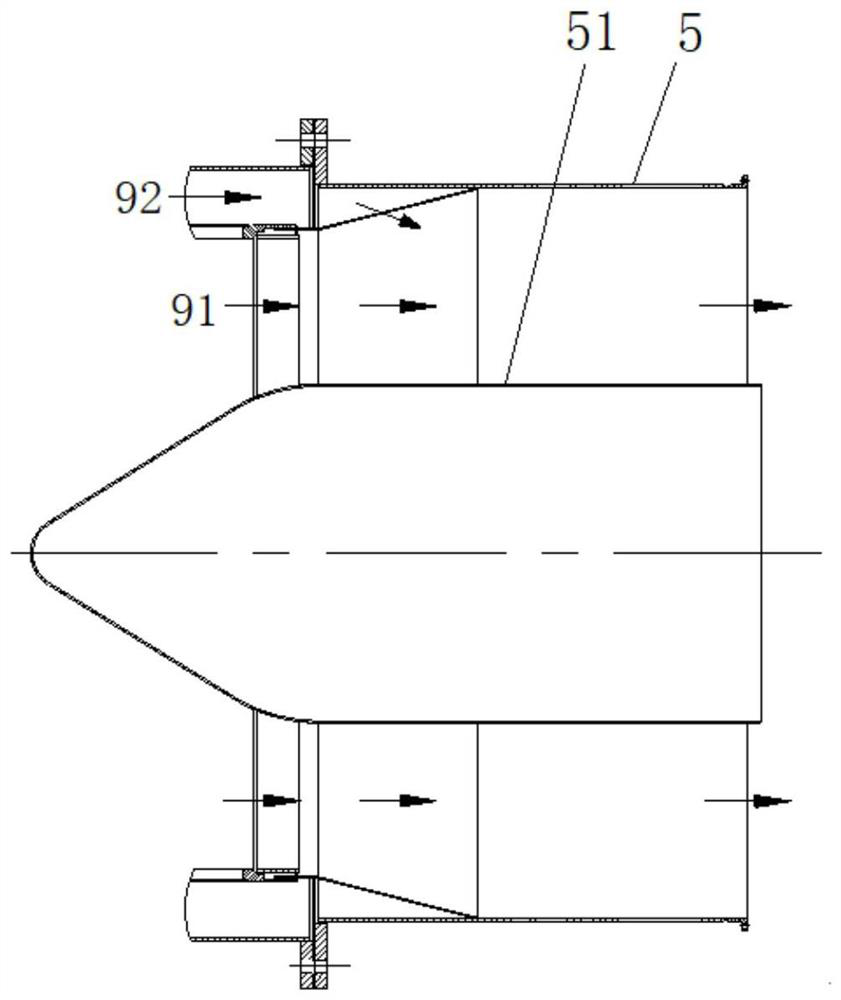

[0022] In order to make the implementation purpose, technical solutions and advantages of the present application clearer, the technical solutions in the embodiments of the present application will be described in more detail below with reference to the accompanying drawings in the embodiments of the present application.

[0023] In order to simulate the high-temperature and high-pressure air intake state of the full-ring ramjet combustion chamber and at the same time effectively protect the test equipment in the cabin, the present application proposes a full-ring ramjet combustion test inlet platform cooled by natural bleed air.

[0024] like Figure 1 to Figure 3 As shown, the full-ring ramming combustion test air intake platform cooled by natural bleed air provided by this application includes: bleed air pipe 1, rectification front connecting plate 2, thermal protection sleeve 3, rectification rear connecting plate 4, transition section 5, stamping Combustion chamber test p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com