New energy battery box detection equipment and detection method

A technology for testing equipment and battery boxes, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of high consumption of human resources, affecting the detection effect, and large size, and achieves a high degree of automation, increasing the detection range, and reducing production. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

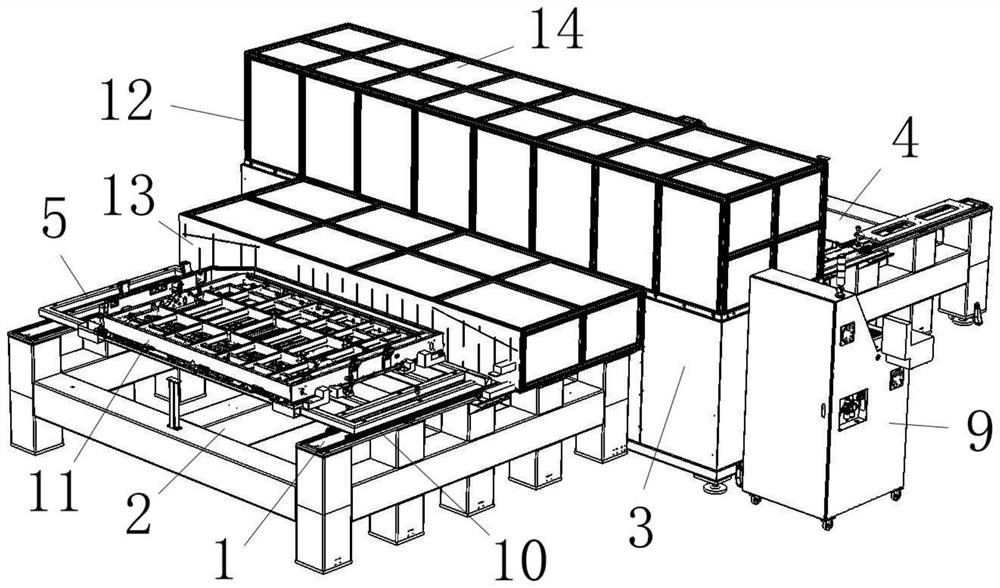

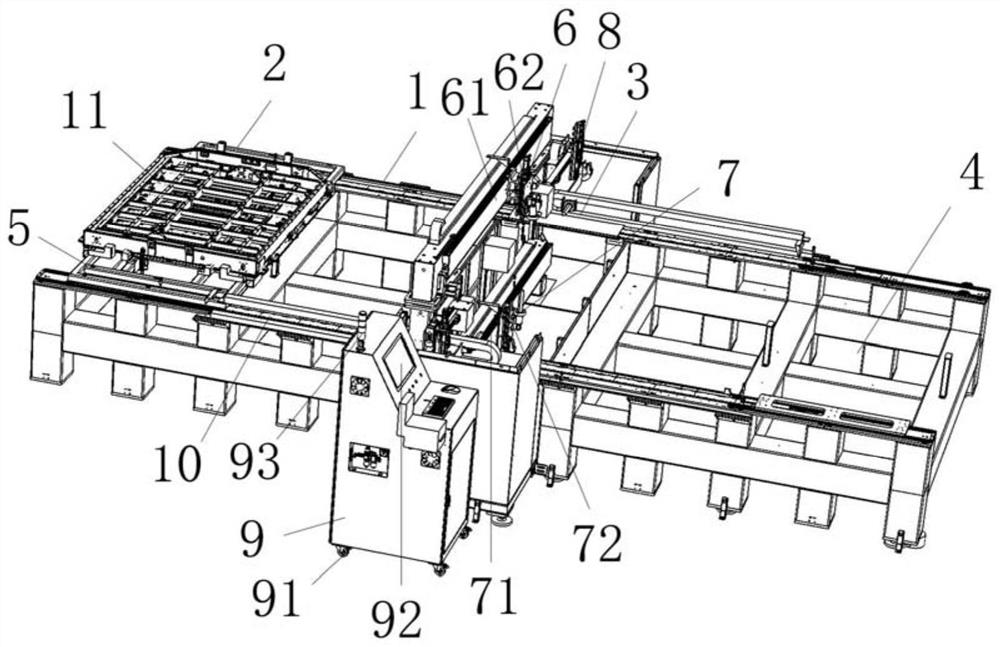

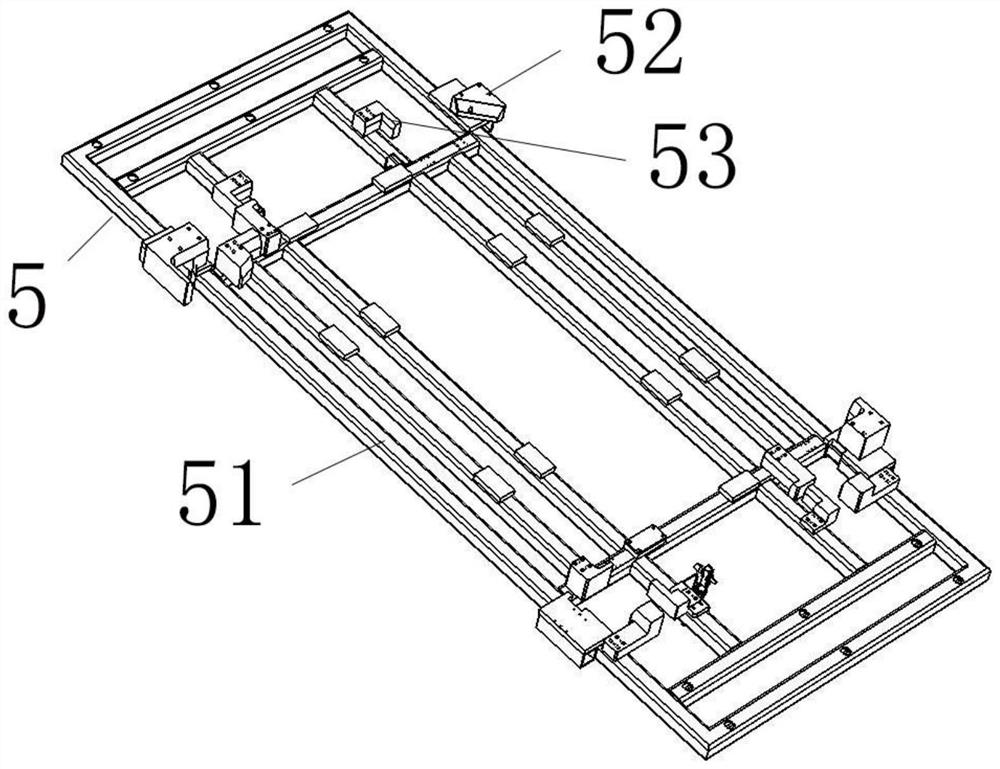

[0066] like Figure 1-4 As shown, a new energy battery box detection device includes a transmission line 1, and the transmission line is provided with a feeding area 2, a detection area 3 and a discharging area 4 in sequence, and a carrier 5 is arranged on the transmission line in the feeding area. , move between the detection area and the blanking area;

[0067] The detection area includes a top detection mechanism 6, a bottom detection mechanism 7 and two side detection mechanisms 8. The top detection mechanism is located above the bottom detection mechanism, and the two side detection mechanisms are located on the top side respectively. Both sides of the surface detection mechanism;

[0068] The top surface detection mechanism includes a first detection movement mechanism 61 and a first detection mechanism 62 moving on the first detection movement mechanism; the first detection mechanism includes a first depth compensation mechanism 63 and several first detection mechanism...

Embodiment 2

[0102] This embodiment is carried out on the basis of the above-mentioned first embodiment, and the same points as the above-mentioned embodiment will not be repeated.

[0103] This embodiment relates to a detection method, which adopts the detection device as described in the first embodiment, and specifically includes the following steps:

[0104] S1. Place the new energy battery box to be tested on the carrier;

[0105] S2. The carrier drives the new energy battery box to be detected to move on the transmission line until it moves to the detection area;

[0106] S3. During the process of step S2, the first depth compensation mechanism monitors the distance between the new energy battery box and the first detection camera in real time, and adjusts the position of the first detection camera so that the new energy battery box always falls into the first detection camera. Detect the detection range of the camera;

[0107] S4, the first detection moving mechanism drives the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com