Tobacco shred impurity detection method and device, computer equipment and storage medium

A detection method and computer program technology, applied in the field of computer program products and shredded tobacco debris detection, can solve problems such as missed detection, false detection, and easy fatigue, and achieve the effects of strong directivity, accuracy and detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] In order to make the purpose, technical solutions and advantages of the present application more clearly understood, the present application will be described in further detail below with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described herein are only used to explain the present application, but not to limit the present application.

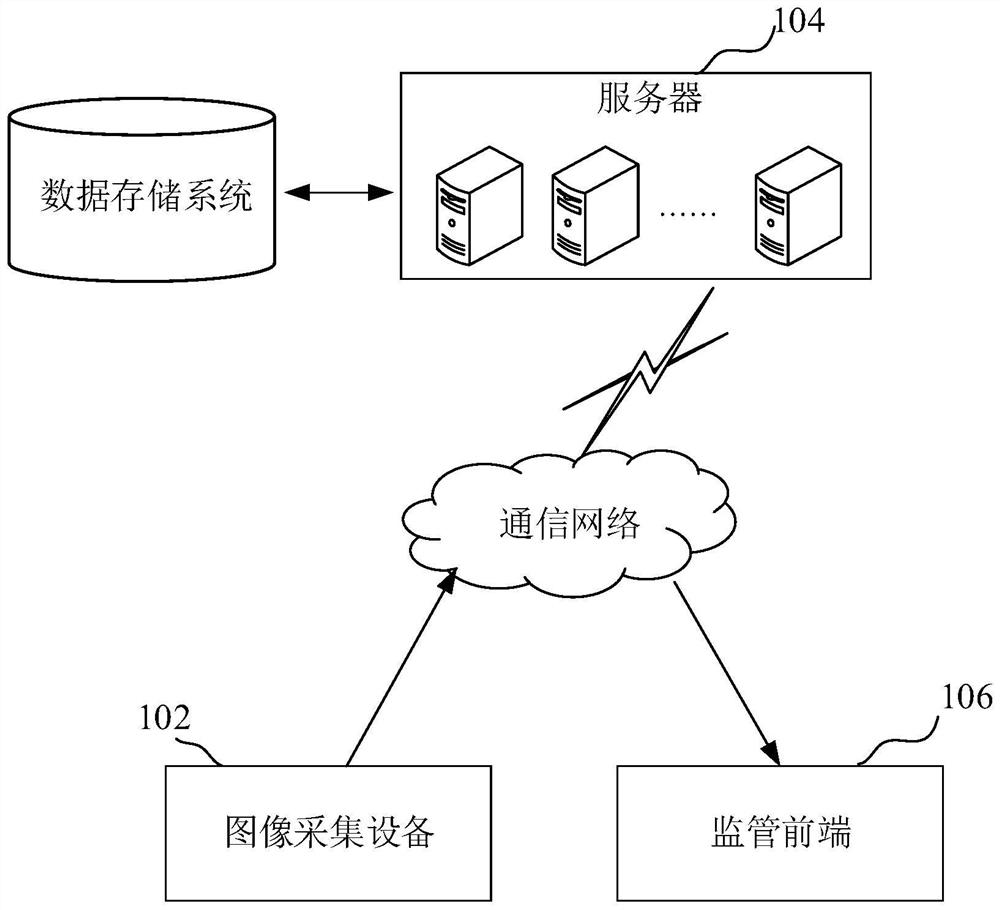

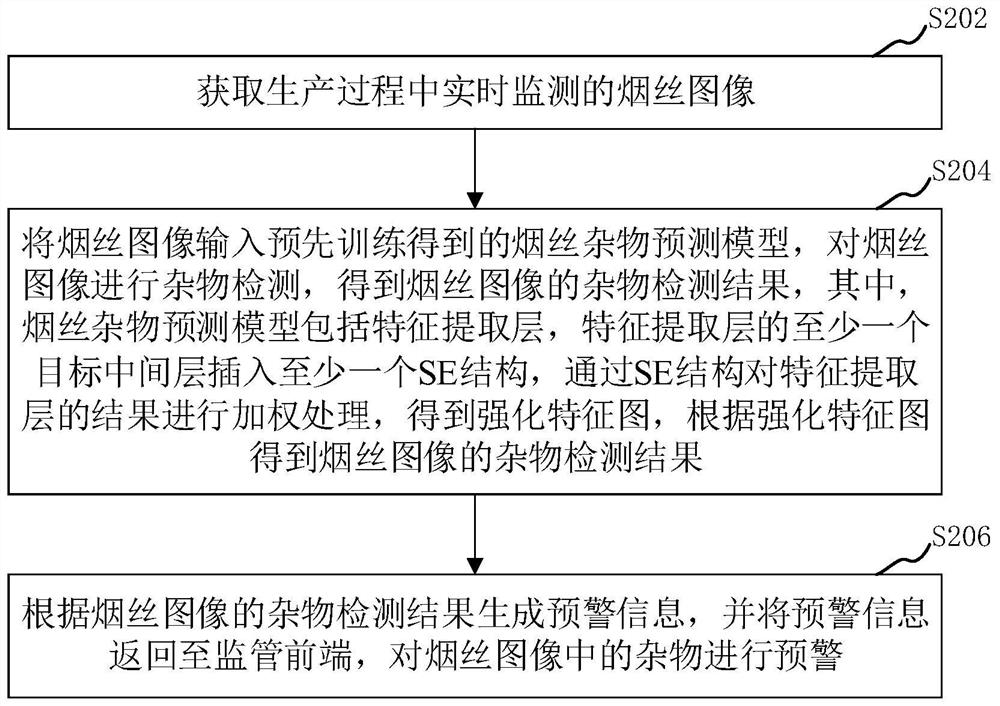

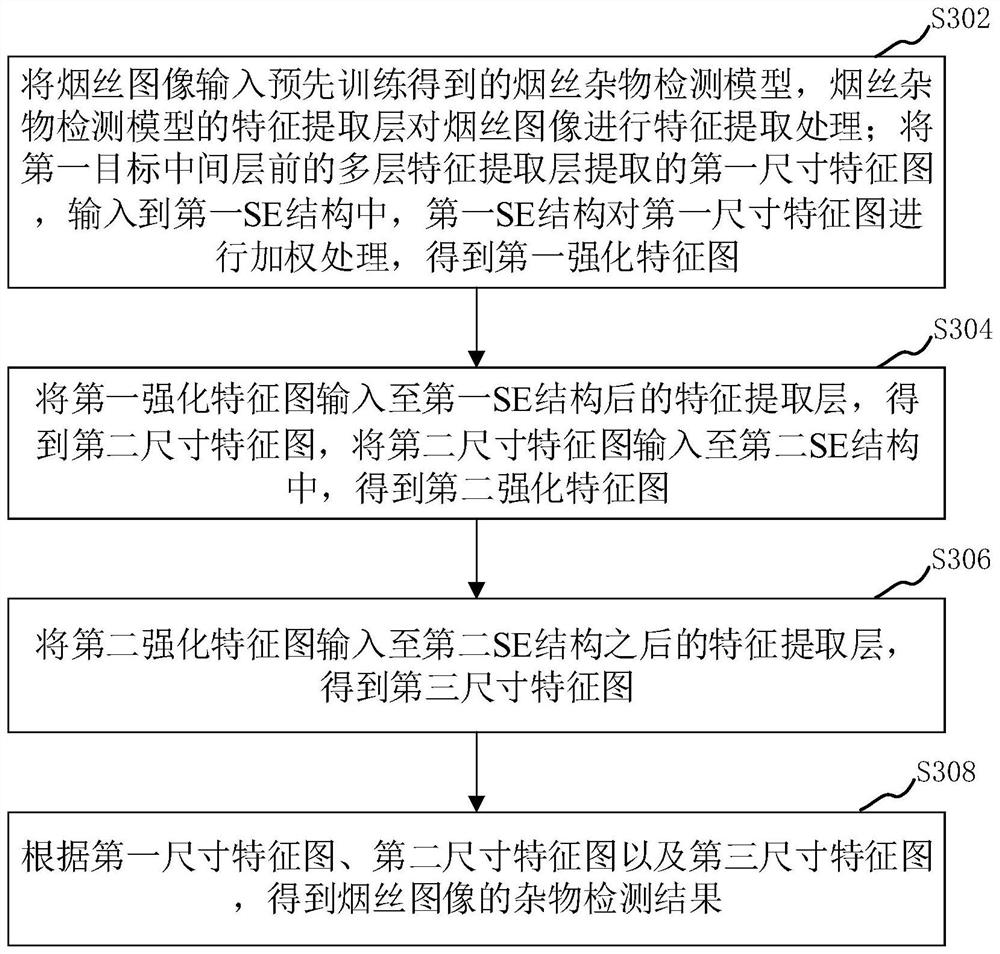

[0054] The method for detecting foreign matter in cut tobacco provided in the embodiments of the present application can be applied to methods such as figure 1 in the application environment shown. The image acquisition device 102 and the supervisory front end 106 communicate with the server 104 through a communication network, respectively. The data storage system may store data that the server 104 needs to process. The data storage system can be integrated on the server 104, or it can be placed on the cloud or other network server. The server 104 acquires the cut to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com