Image sensor and method for forming pixel structure of image sensor

An image sensor and pixel structure technology, applied in semiconductor devices, radiation control devices, etc., can solve the problem of image sensor white pixels, achieve the effect of improving white pixels and reducing metal ion pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

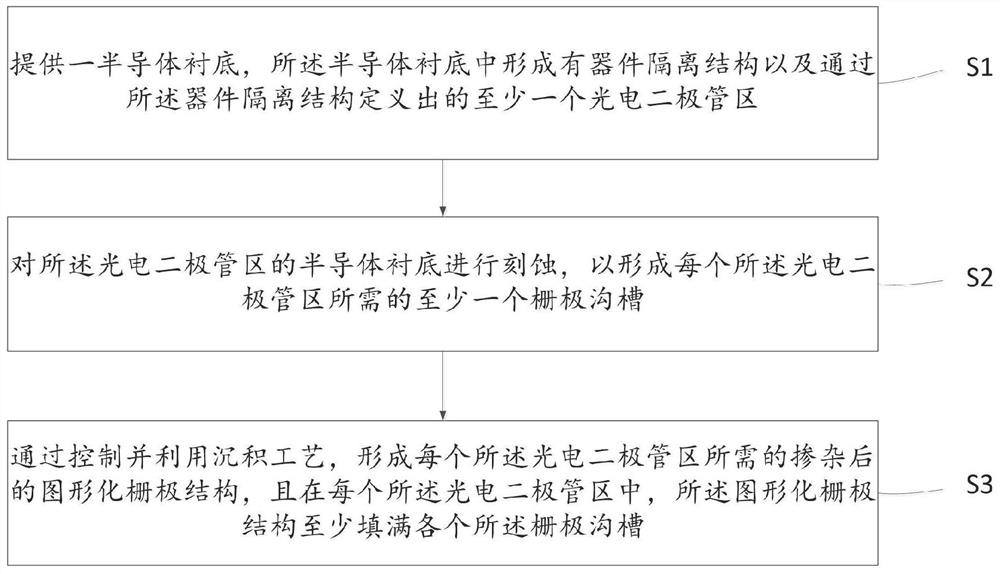

Method used

Image

Examples

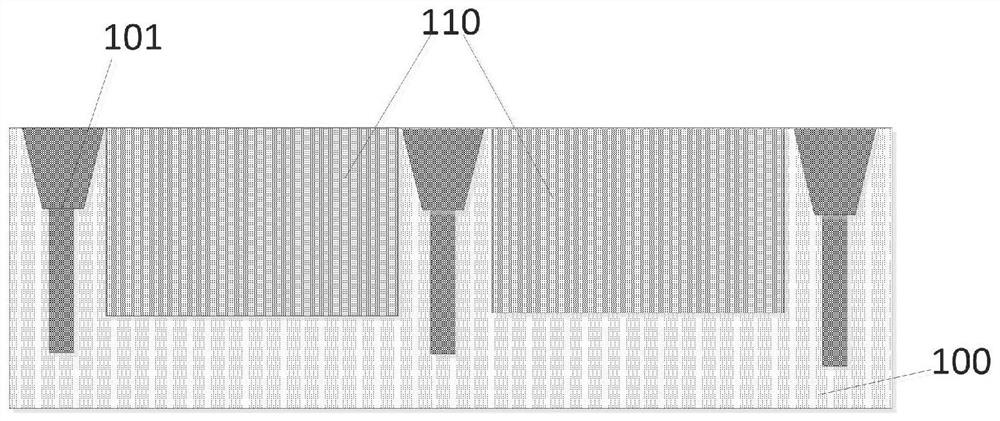

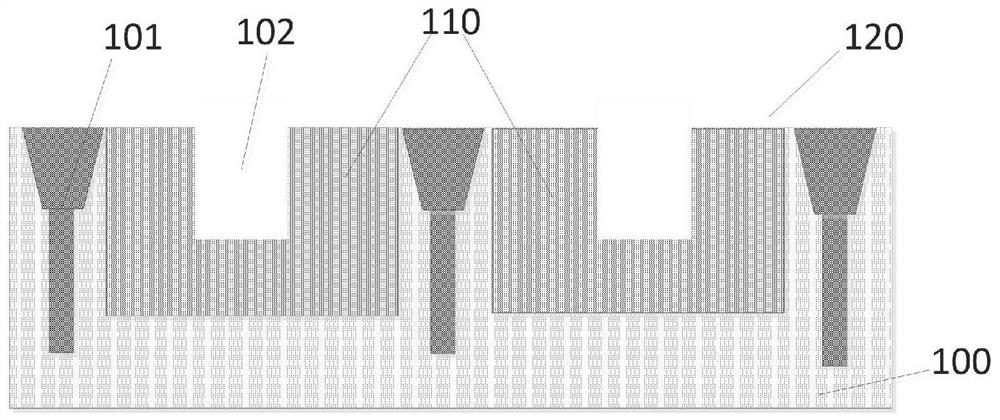

Embodiment Construction

[0029] As described in the background art, at present, with the continuous advancement of the standard CMOS process level and the market demand for small-sized pixels, the pixel size of the CMOS image sensor has been gradually reduced from 5.6 mm to 1.0 mm. Nowadays, in order to increase the area of the photodiode region PD, the pixel size has to be reduced. Therefore, the vertical gate oxide process emerges as the times require. Specifically, the existing method for forming vertical gate oxide is as follows: using silane to grow polysilicon in a low-voltage furnace tube, and then performing P ion implantation on the surface of the polysilicon layer formed as the gate structure to improve the K value of the polysilicon layer, In turn, the equivalent gate oxide thickness is reduced; however, the existing formation method will cause metal contamination in the CMOS image sensor product under the condition of small size, which will eventually cause the problem of white pixels.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com