Automatic packaging and sterilizing line provided with pushing mechanism and used for margarya melanioides rice noodle seasoning bags

An automatic packaging and material pushing mechanism technology, which is applied in packaging sterilization, packaging, food processing, etc., can solve problems such as easy dropping of machines, secondary pollution, and unprotected conveyor belts, achieving high adjustability and improving efficiency , the effect of strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

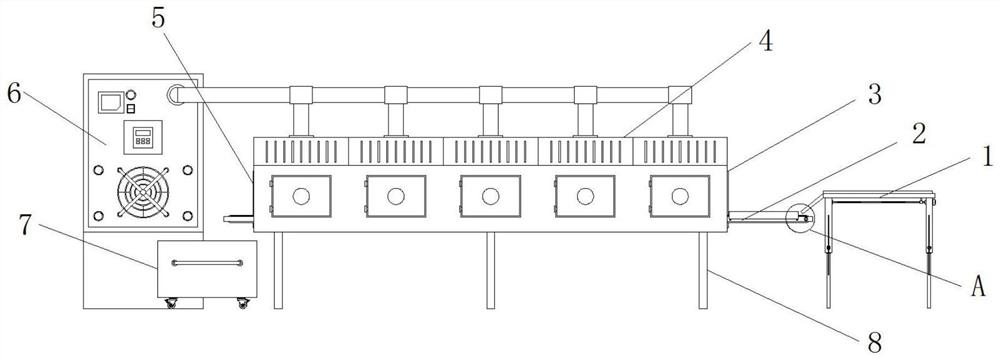

[0027] Example 1: see Figure 1-6 , an automatic packaging and sterilization line for snail powder seasoning packets provided with a pushing mechanism, including a tunnel microwave sterilizer 4 and a microwave control host 6, and the left side of the tunnel microwave sterilizer 4 is provided with a microwave control host 6. The right side of the microwave sterilizer 4 is provided with a feeding table 1, the left side wall of the tunnel type microwave sterilizer 4 is provided with a tunnel outlet 5, the right side wall of the tunnel type microwave sterilizer 4 is provided with a tunnel entrance 3, and the tunnel type microwave sterilizer 4 is provided with a tunnel entrance 3. The bottom end of the machine 4 is provided with a device bracket 8, and a transport table 2 is installed inside the tunnel microwave sterilizer 4. The transport table 2 is horizontally erected from the tunnel entrance 3 to the tunnel outlet 5, and the interior of the transport table 2 is provided with a m...

Embodiment 2

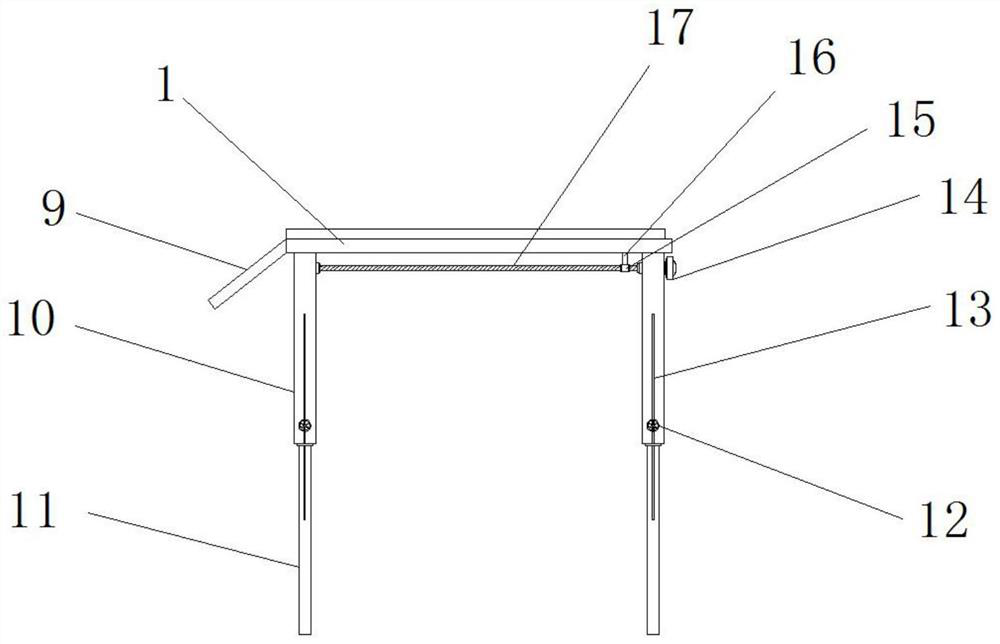

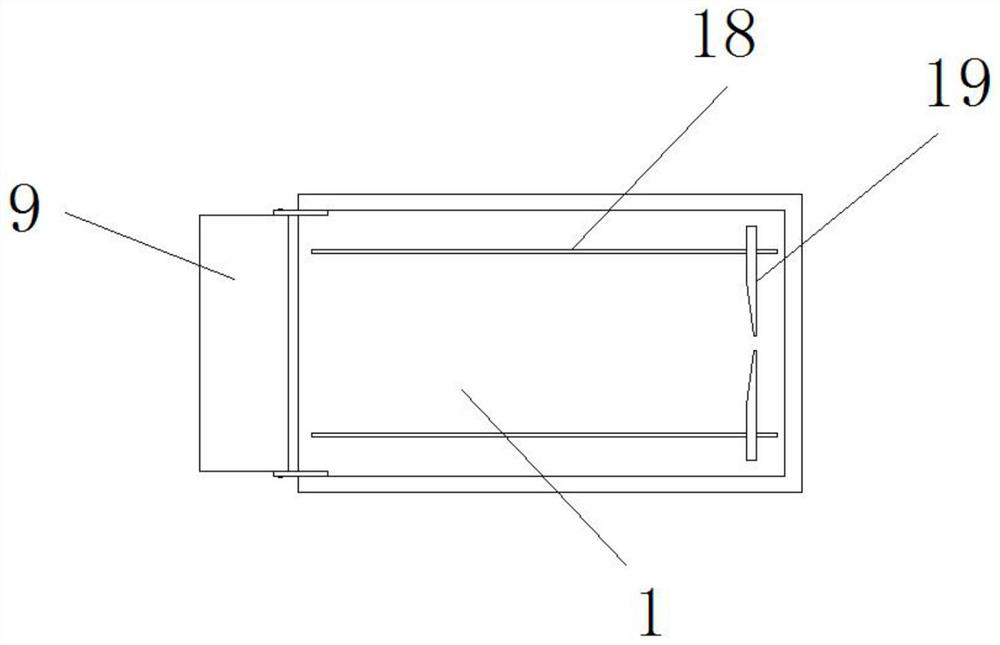

[0030] Example 2: A threaded rod 17 is arranged between the hollow columns 10, two sets of threaded rods 17 are arranged, a threaded block 15 is sleeved on the outside of the threaded rod 17, and a connecting rod 16 is fixedly connected to the top of the threaded block 15. 1 is provided with a moving groove 18 inside. The moving grooves 18 are provided with two groups and are parallel to each other. A pushing plate 19 is embedded in the interior of the moving groove 18. The bottom ends of the pushing plates 19 are respectively fixedly connected with the connecting rod 16. The right side of the feeding table 1 is provided with a servo motor 14, and the servo motor 14 is provided with two groups. The servo motors 14 are respectively fixedly connected with the threaded rods 17. The material guide inclined plate 9, the bottom end of the material guide inclined plate 9 is located above the material conveying belt 20, the material guide inclined plate 9 is hinged at the loading table...

Embodiment 3

[0032] Example 3: Hollow columns 10 are fixedly connected to both sides of the bottom end of the feeding table 1, and vertical rods 11 are sleeved inside the hollow columns 10. Adjustment grooves 13 are provided inside the vertical rods 11 and the hollow column 10. A locking bolt 12 is fixedly connected between the rod 11 and the hollow column 10;

[0033] Specifically, as figure 1 , figure 2 , image 3 and Figure 5As shown in the figure, the fixed position between the hollow column 10 and the vertical rod 11 of the feeding table 1 can be adjusted, the locking bolt 12 is loosened, the hollow column 10 is pulled up, and the feeding table 1 is raised to the required height and then locked in position. The drop height of the bag can be adjusted by adjusting the height, which is suitable for most of the tunnel microwave sterilizers on the market, and has strong applicability.

[0034] Working principle: When the present invention is in use, the staff places the material bag ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com