Method for measuring most negative cathodic protection potential of steel

A cathodic protection and potential technology, which is applied in the direction of measuring devices, analyzing materials, and using stable tension/pressure to test the strength of materials, etc., can solve the problem of the most negative cathodic protection potential determination method, no evaluation of metal test method standards, and anodes Dissolution can not be effectively suppressed and other problems, to achieve the effect of inhibiting oxygen absorption corrosion, solving easy corrosion, and preventing hydrogen embrittlement cracking

Pending Publication Date: 2022-07-08

JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

View PDF1 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] In the marine environment, cathodic protection is usually used to inhibit the corrosion of steel. Cathodic protection must first determine a reasonable cathodic protection potential range. If the potential is too positive, anodic dissolution cannot be effectively suppressed, and if the potential is too negative, the steel will be "overprotected", resulting in Hydrogen evolution occurs on the surface of the material, which absorbs on the surface of the substrate and penetrates into the interior of the metal, making hydrogen embrittlement cracking more likely to occur

Anode dissolution is often accompanied by phenomena such as surface corrosion and anode slime generation, which can be directly observed or judged by ch

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

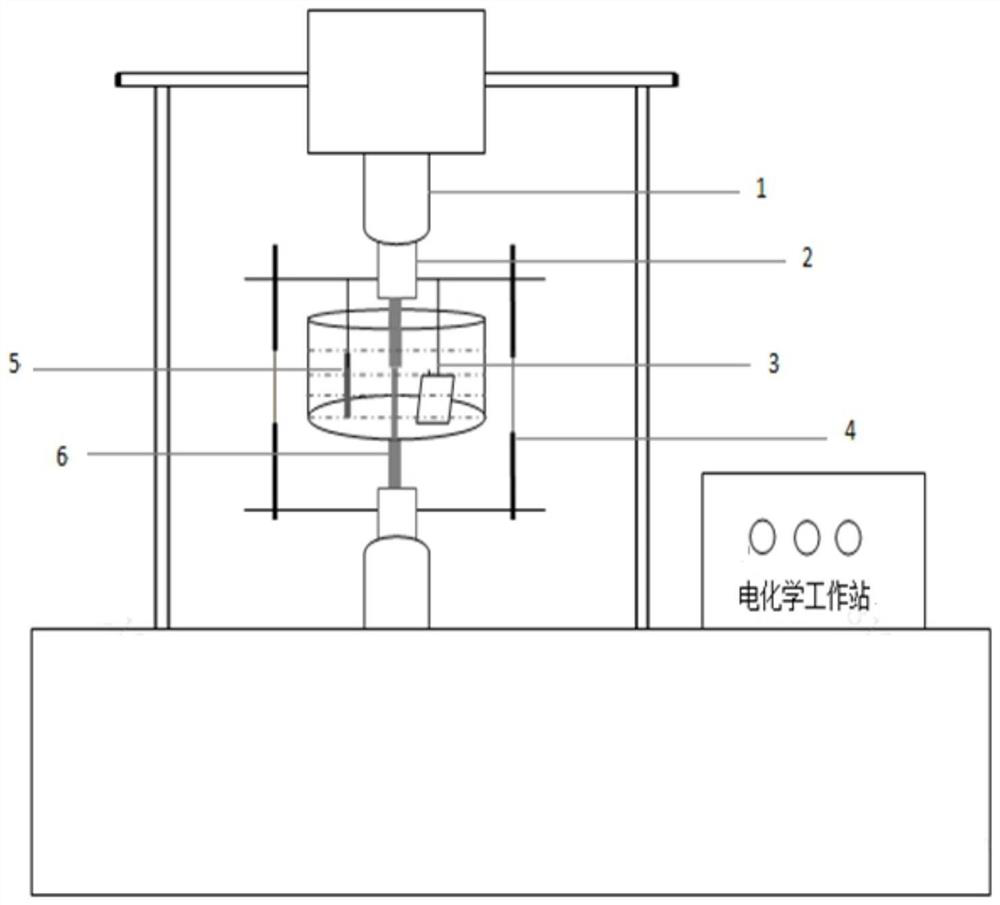

The invention relates to a method for measuring the most negative cathodic protection potential of steel. The method comprises the following steps: (1) preparing a test solution; (2) electrochemical testing: measuring self-corrosion and inflection point potential; (3) a slow strain rate stress corrosion test: researching the hydrogen embrittlement sensitivity of the sample in the test solution under different cathodic polarization potentials, and calculating a hydrogen embrittlement coefficient; (4) TDS test: taking the fracture part of the sample after the test in the step (3) is finished, determining the hydrogen content in the sample after different polarization potential tests, and calculating the hydrogen permeation rate of the sample corresponding to different potentials in the stress corrosion test process in the step (3); (5) fracture morphology analysis; and (6) data analysis: drawing a hydrogen embrittlement coefficient-polarization potential curve and a hydrogen permeation rate-polarization potential curve according to results of the steps (3) and (4) in combination with the fracture morphology in the step (5) so as to determine the most negative cathodic protection potential of the sample.

Description

technical field [0001] The invention relates to a method for determining the most negative cathodic protection potential of high-strength steel, and belongs to the technical field of material corrosion resistance research. Background technique [0002] With the development of my country's marine industry and the continuous development of marine resources, the development and application of high-strength steel for marine engineering has become more and more extensive. While its strength has been continuously improved, its corrosion resistance has also attracted much attention. [0003] In the marine environment, cathodic protection is usually used to inhibit the corrosion of steel. The cathodic protection must first determine a reasonable cathodic protection potential range. If the potential is too positive, the anodic dissolution cannot be effectively suppressed, and if the potential is too negative, the steel will be "overprotected", resulting in The surface of the material...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N3/02G01N3/04G01N3/08G01N17/00G01N17/02

CPCG01N3/02G01N3/04G01N3/08G01N17/006G01N17/02

Inventor 张欣翁韶华孙以春许晓红白云黄镇范海东周阳

Owner JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com