Batch hoisting load analysis method for steel members

An analysis method and technology for steel components, applied in the field of hoisting analysis, can solve problems such as low calculation efficiency, and achieve the effects of saving labor costs, improving analysis efficiency, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

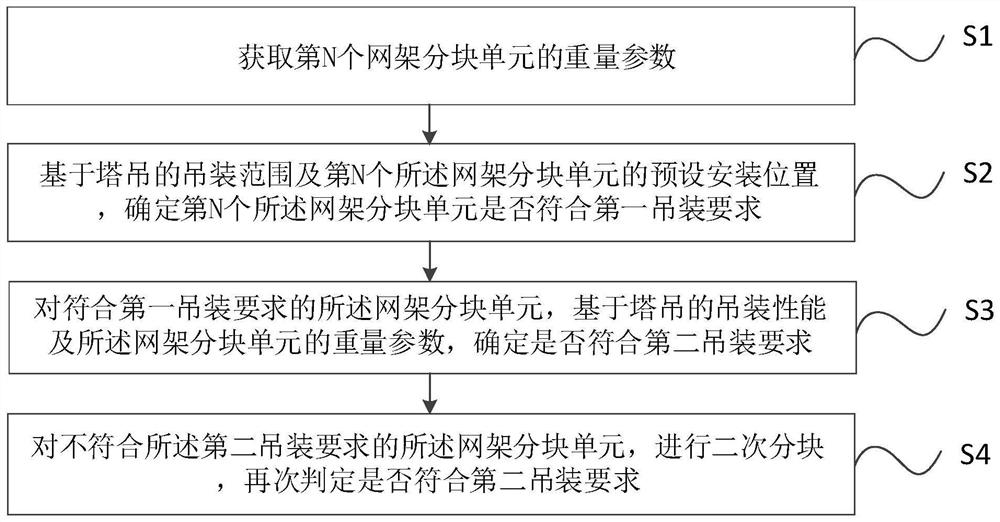

[0041] combine Figure 1-Figure 6 As shown, the method for analyzing the batch hoisting weight of steel components provided in this embodiment includes:

[0042] S1. Obtain the weight parameter of the N-th grid block unit. Among them, N is a positive integer.

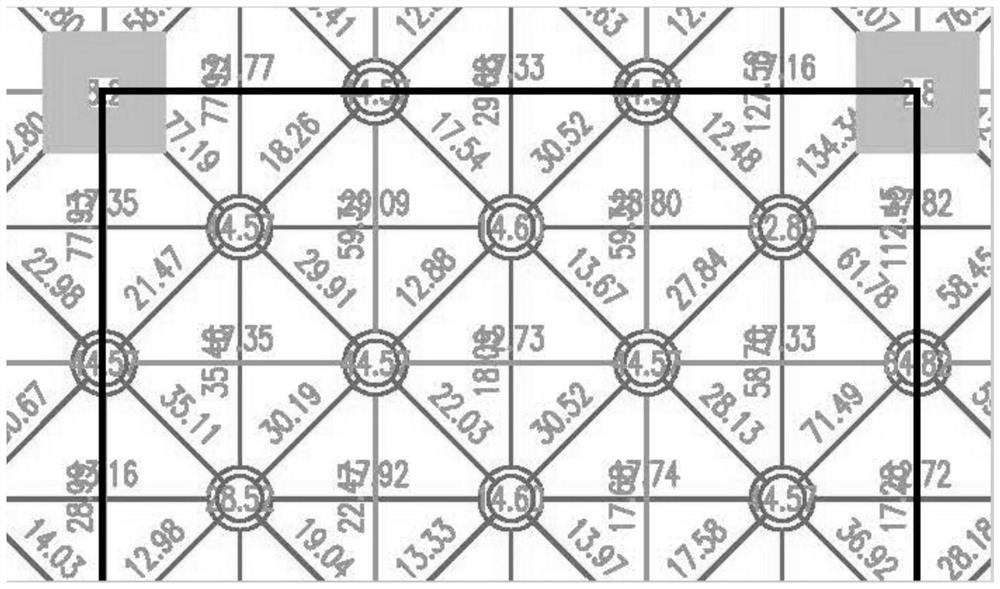

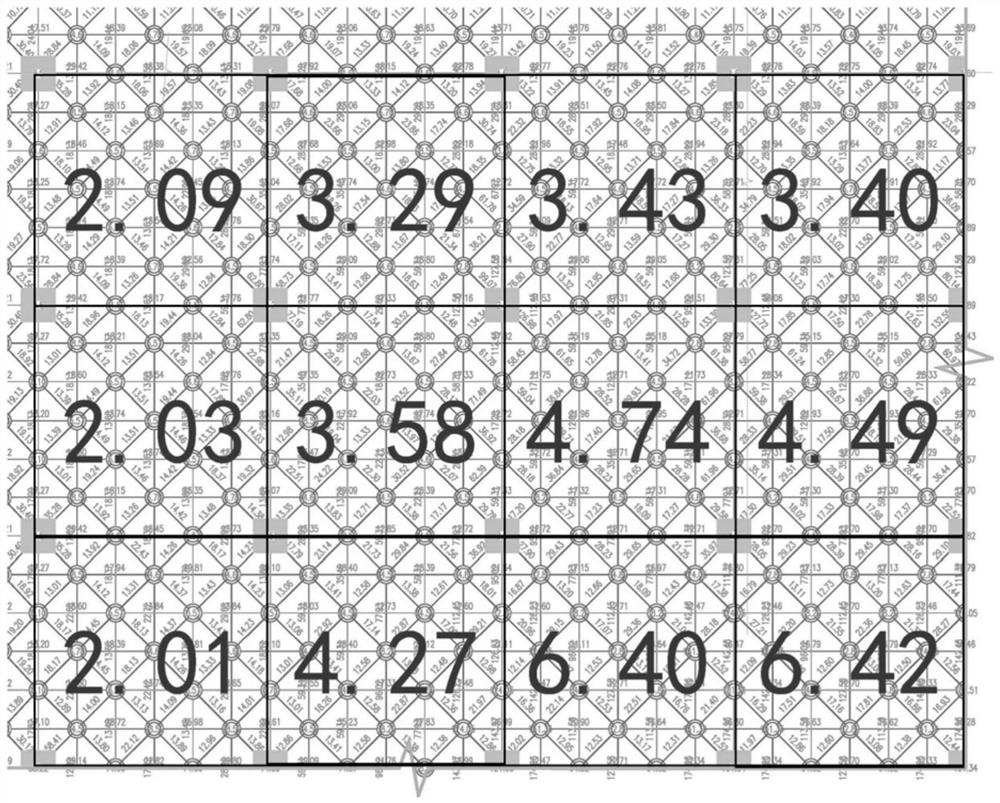

[0043] Preferably, in order to complete the assembly of a space grid, it is necessary to first divide the space grid into N grid block units; Figure 4 As shown in the figure, due to the limitation of the hoisting range of the tower crane, and at the same time, each tower crane has the limitation of the hoisting capacity according to its own parameters, therefore, in the hoisting process of the grid block unit, it is necessary to carry out N grid block units one by one. Analysis, according to the predetermined installation position of each grid block unit, determine whether it is within the hoisting range of the tower crane, and according to the weight of each grid block unit, determine whether it is within the range ...

Embodiment 2

[0077] The present embodiment provides a batch hoisting weight analysis device for steel components, including:

[0078] The acquisition module is used to acquire the weight parameter of the Nth grid block unit;

[0079] The judgment module is used to determine whether the N-th grid frame sub-unit meets the first hoisting requirement based on the hoisting range of the tower crane and the preset installation position of the N-th grid frame sub-unit; The required grid block unit is determined based on the hoisting performance of the tower crane and the weight parameters of the grid block unit to determine whether it meets the second hoisting requirement; for the grid unit that does not meet the second hoisting requirement The block unit is divided into two blocks, and it is judged again whether it meets the second hoisting requirements; wherein, N is a positive integer.

[0080] This embodiment also provides an electronic device, comprising: a processor and a memory, where the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com