Super capacitor production line and circuit detection system thereof

A supercapacitor and circuit detection technology, applied in electronic circuit testing, hybrid capacitor terminals, hybrid/electric double-layer capacitor manufacturing, etc., can solve the problem of inconvenient correction of capacitor pins, inconvenient inspection process, capacitor grinding and trimming, and low circuit inspection and inspection efficiency. and other problems, to achieve the effect of convenient access, improve production efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

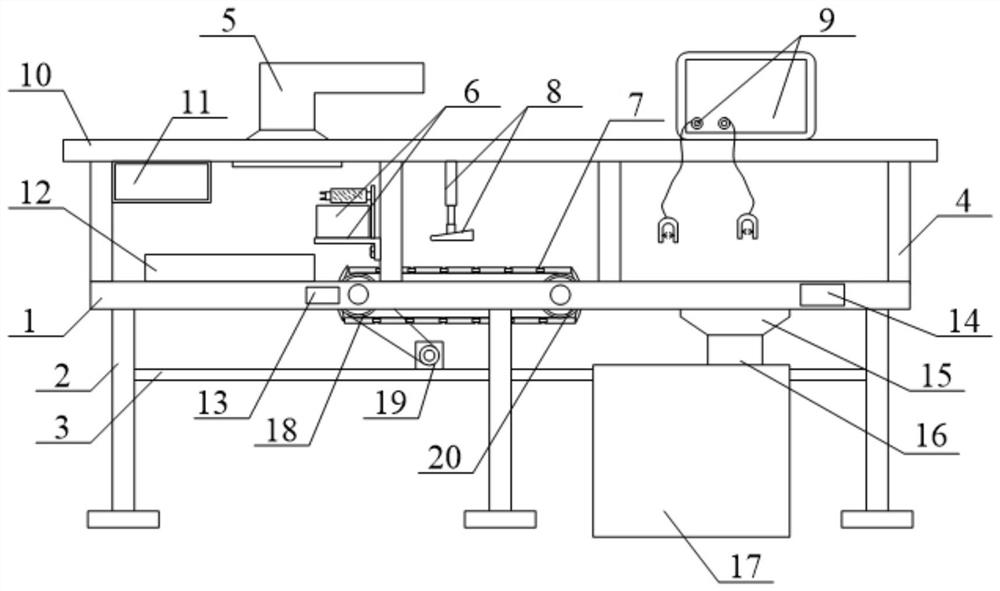

[0038] as attached figure 1 As shown, the present invention provides a super capacitor production line, including a production line console 1, a support column 2, a shaping rod 3, an upper support rod 4, a welding fume discharge pipe 5, a capacitor grinding and dressing frame assembly 6, a production line conveyor belt assembly 7, Stitch correction and opening block assembly 8, circuit detection device assembly 9, upper storage board 10, storage box 11, welding table 12, first controller 13, second controller 14, product collection bucket 15, buffer tube 16, product collection box 17, driving roller 18, conveying motor 19 and driven roller 20,

[0039] The support columns 2 are respectively bolted to the lower position of the production line console 1; the shaping rods 3 are laterally bolted to the position between the two support columns 2 set on the rear side; one end of the upper support rod 4 is The bolt is connected to the upper part of the production line console 1, and...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap