Automatic shaping mechanism for battery plate assembly

A battery and pole plate technology, applied in the field of automatic shaping mechanism for battery pole plate assembly, can solve the problems of inability to effectively control the conveying position, affecting assembly efficiency, affecting production efficiency, etc., to improve shaping and assembly efficiency, reduce transportation conversion time, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to deepen the understanding of the present invention, the present invention will be described in further detail below with reference to the embodiments, which are only used to explain the present invention and do not constitute a limitation on the protection scope of the present invention.

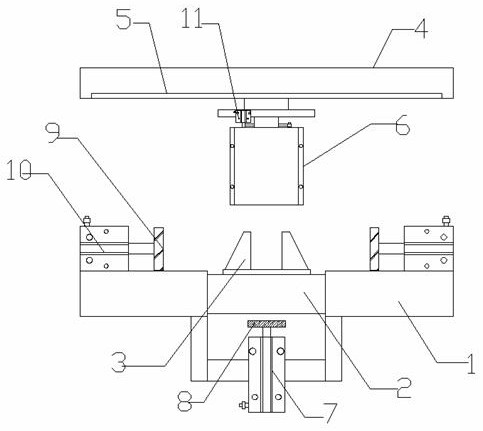

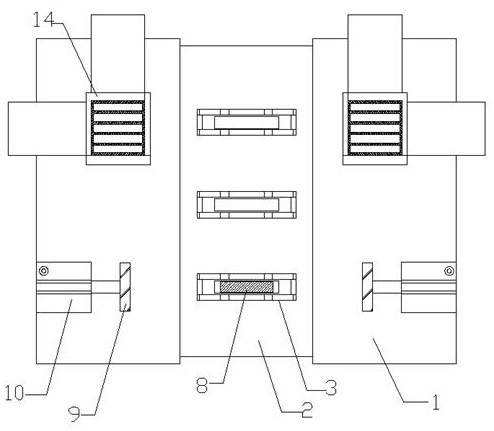

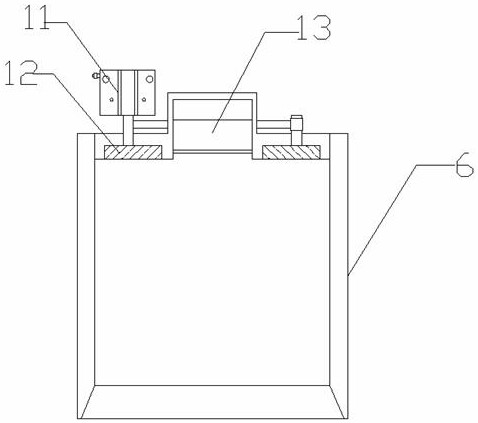

[0022] like Figure 1-3 As shown in the figure, this embodiment provides an automatic shaping mechanism for battery plate assembly, including a workbench 1, a conveyor chain 2 is arranged in the middle of the workbench 1, a discharge seat 3 is provided on the conveyor chain 2, and the discharge base 3 is provided with more than One, the pole group is conveyed by being placed on the discharge seat 3 and positioned on the conveyor chain 2.

[0023] There are clamping mechanisms on both sides of the conveyor chain 2, and the clamping mechanism includes a clamping plate 9 and a clamping cylinder 10; the clamping cylinders 10 are symmetrically arranged on the table 1 on both sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com