Movable trolley capable of achieving annular production of beams and slabs

A ring, trolley technology, applied in ceramic molding workshops, ceramic molding machines, manufacturing tools, etc., can solve the problems of limited prefabrication site, high construction schedule requirements, scattered production areas, etc., to shorten the production cycle and reduce labor. The effect of investing in and improving the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] This embodiment is a movable trolley for realizing the circular production of prefabricated box girders.

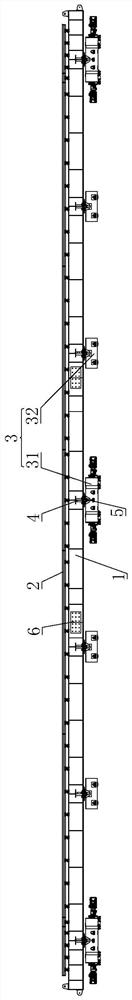

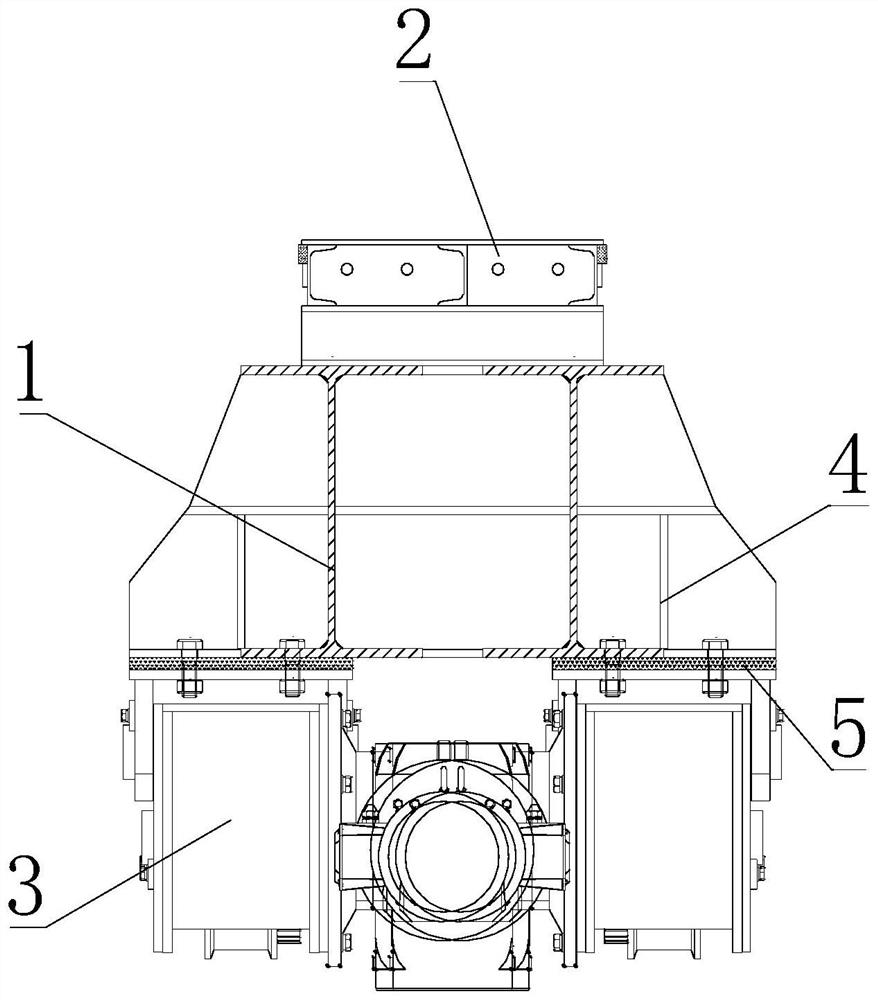

[0035] see Figure 1-Figure 3 As shown, the present invention is a movable trolley capable of realizing circular production of beams and slabs, including a main beam 1 of the trolley and a driving rail 7, the main beam 1 of the trolley is spliced and formed by a plurality of channel steels, and the main beam 1 of the trolley is provided with multiple groups And through the fixed connection of the connecting support plate 6, the bottom of the trolley main beam 1 is equipped with a platform wheel box 3, and the trolley main beam 1 is slidably arranged on the driving rail 7 through the platform wheel box 3.

[0036] The main girder 1 of the trolley in this embodiment, as the entire main load-bearing member, mainly bears the pressure of the upper concrete and the self-weight of the formwork during pouring. It is composed of beams, longitudinal beams, steel plates, a...

Embodiment 2

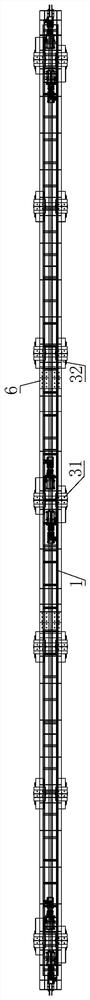

[0049] This embodiment is a movable trolley for realizing double T-beam ring production.

[0050] see Figure 9-Figure 11 As shown, the trolley main beam 1 includes two sets of main connecting beams 11 arranged side by side. The main connecting beam 11 is provided with a secondary beam 12 inside, and the main connecting beam 11 and the secondary beam 12 are fixedly connected by a transverse beam 13 .

[0051] The main connecting beam 11 lower end is equipped with a support wheel box 33, and the supporting wheel box 33 is used to support the main connecting beam 11 to slide on the driving rail 7.

[0052] The support wheel box 33 includes a support shaft 331 fixedly installed on the main connecting beam 11 , and a support roller 332 is rotatably installed on the support shaft 331 through a bearing 333 .

[0053] The main connecting beam 11 adopts the channel steel of model 28b, and the secondary beam 12 adopts the channel steel of model 18, both of which bear the upper concret...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com