Method for recycling lithium from waste lithium ion battery

A lithium-ion battery and lithium recovery technology, applied in the field of lithium recovery, can solve the problems of complex steps, large environmental pollution, high cost, etc., and achieve the effect of promoting recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

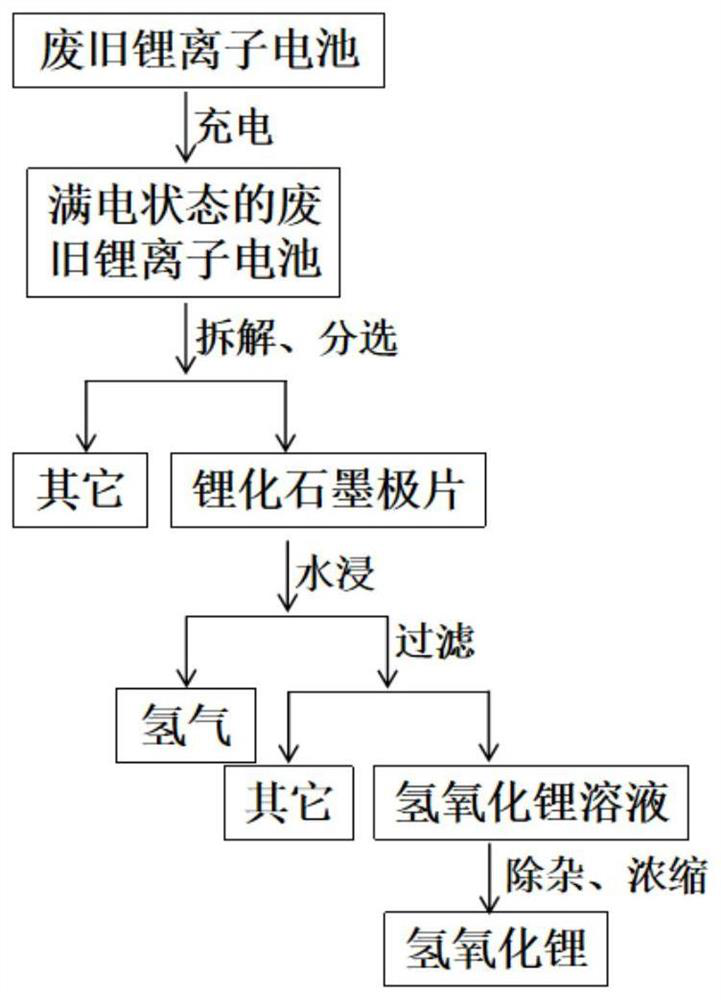

[0039] A method for recovering lithium from waste lithium-ion batteries, comprising the steps of:

[0040] (1) Charge the recovered waste lithium iron phosphate lithium-ion battery at a current density of 1C until it is fully charged.

[0041] (2) Disassemble the waste lithium iron phosphate lithium-ion battery in a fully charged state to obtain a positive electrode sheet after delithiation, a lithiated graphite negative electrode sheet, a separator, and the like.

[0042] (3) The lithiated graphite negative electrode sheet obtained above was soaked in deionized water at 25° C. for 1 hour.

[0043] (4) filter after soaking to obtain an aqueous solution of lithium hydroxide.

[0044] (5) adding the obtained lithium hydroxide aqueous solution to an impurity remover to remove impurities, and after removing impurities, heating and concentrating to remove water at 98° C. to obtain lithium hydroxide solid powder.

[0045] (6) According to the ratio of the lithium content of the fi...

Embodiment 2

[0047] A method for recovering lithium from waste lithium-ion batteries, comprising the steps of:

[0048] (1) Charge the recovered waste nickel-cobalt-manganese ternary lithium-ion battery at a current density of 1C until it is fully charged.

[0049] (2) Disassemble the waste nickel-cobalt-manganese ternary lithium-ion battery in a fully charged state to obtain a positive electrode sheet, a lithiated graphite negative electrode sheet, a separator and the like after delithiation.

[0050] (3) The lithiated graphite negative electrode sheet obtained above was soaked in deionized water at 25° C. for 1 hour.

[0051] (4) filter after soaking to obtain an aqueous solution of lithium hydroxide.

[0052] (5) adding the obtained lithium hydroxide aqueous solution to an impurity removing agent to remove impurities, and after removing impurities, heating and concentrating to remove water at 98° C. to obtain lithium hydroxide solid powder.

[0053] (6) According to the ratio of the l...

Embodiment 3

[0055] A method for recovering lithium from waste lithium-ion batteries, comprising the steps of:

[0056] (1) Charge the recovered waste lithium cobalt oxide lithium-ion battery at a current density of 1C until it is fully charged.

[0057] (2) Disassemble the waste lithium cobalt oxide lithium ion battery in a fully charged state to obtain a positive electrode sheet after delithiation, a lithiated graphite negative electrode sheet, a separator, and the like.

[0058] (3) The lithiated graphite negative electrode sheet obtained above was soaked in deionized water at 25° C. for 1 hour.

[0059] (4) filter after soaking to obtain an aqueous solution of lithium hydroxide.

[0060] (5) adding the obtained lithium hydroxide aqueous solution to an impurity removing agent to remove impurities, and after removing impurities, heating and concentrating to remove water at 98° C. to obtain lithium hydroxide solid powder.

[0061] (6) According to the ratio of the lithium content of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com