Circular saw blade and method for manufacturing circular saw blade

A circular saw blade and disc-shaped technology, which is applied in the manufacturing field of circular saw blades and circular saw blades, can solve problems such as intermittent frequency deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

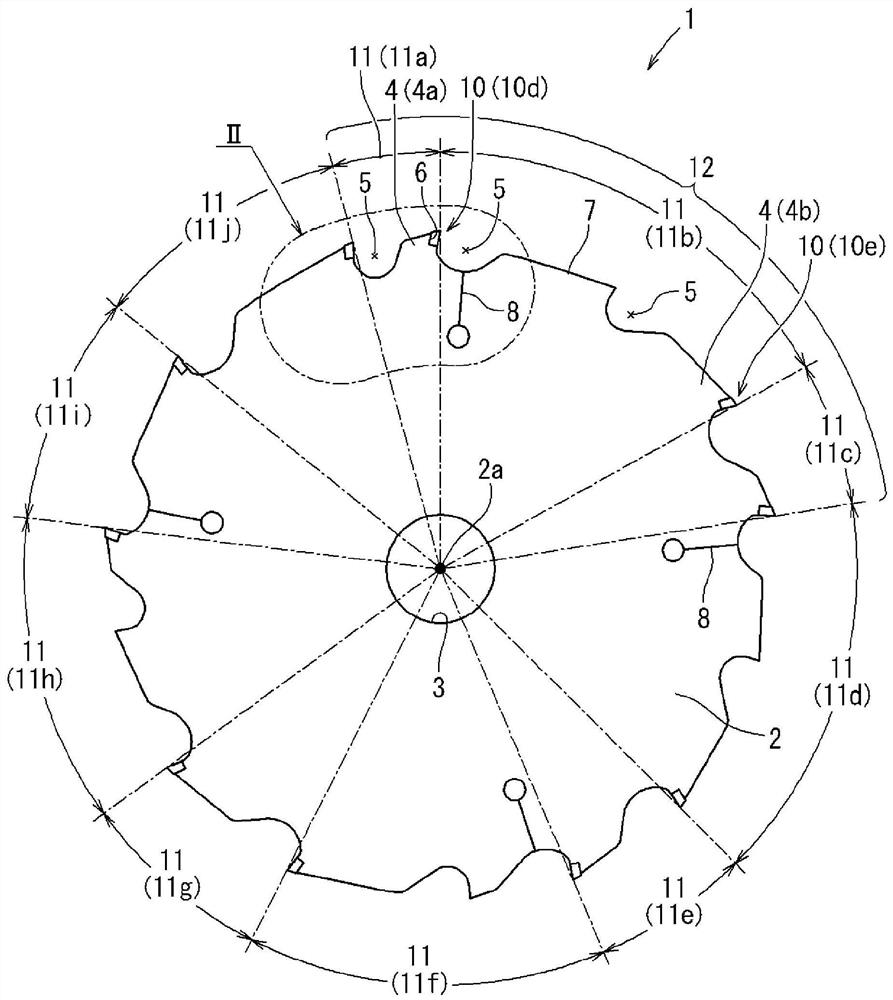

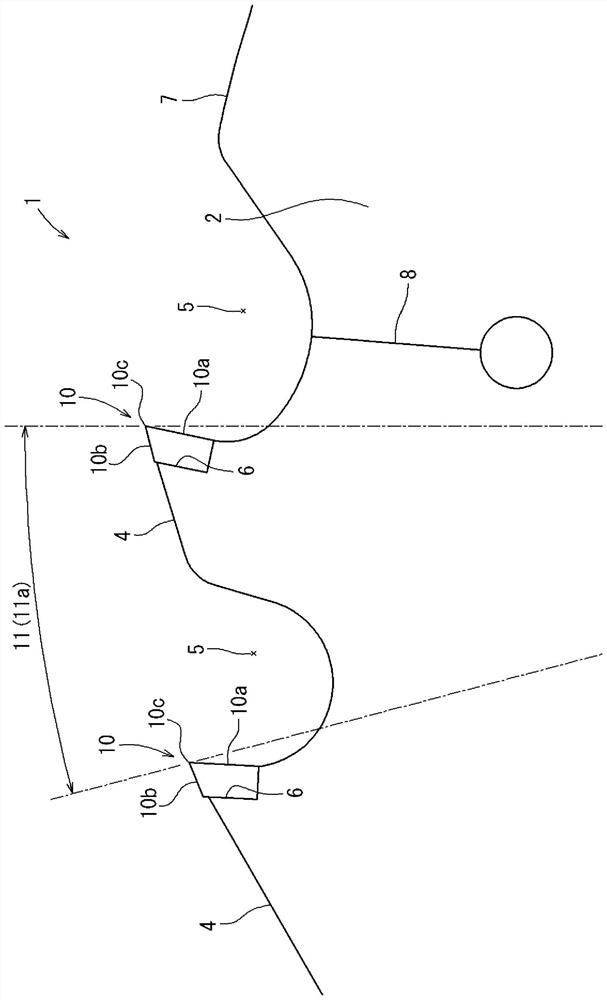

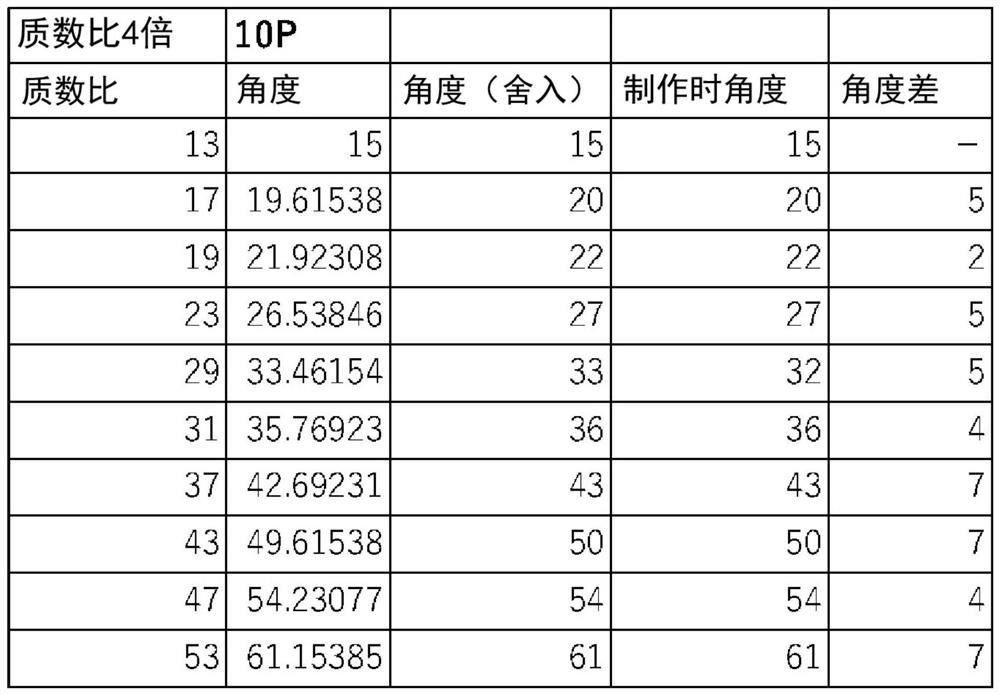

[0043] based on Figures 1 to 21 , the first embodiment of the present disclosure will be described. likefigure 1 As shown, the circular saw blade 1 has a disk-shaped base body 2 and a plurality of cutting tips 10 joined to the outer periphery of the base body 2 . The circular saw blade 1 is not a structure in which a plurality of base bodies 2 are joined, for example, but is used as a single body at the time of cutting. The circular saw blade 1 is rotatably attached to a cutting tool such as a rechargeable battery-type electric circular saw or a stationary circular saw blade cutter, for example. With regard to the circular saw blade 1, the base body 2 is rotated to form grooves in the workpiece with the respective cutting tips 10, and finally the workpiece is cut. The workpiece to be cut is, for example, wood, wood materials, resin materials, composite materials, or ceramic materials such as wall panels. Or the workpiece to be cut is carbon steel, rolled steel for general ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com