Cutter resistant to vibration

A cutting tool and anti-vibration technology, which is applied in the field of cutting tools, can solve problems such as fastener deformation, blade vibration, and chipping, and achieve the effects of reducing blade deformation, prolonging service life, and improving force distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

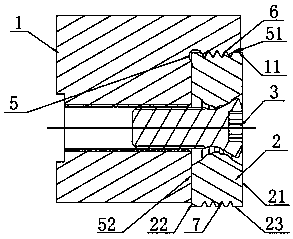

[0010] The present invention will be further described below in conjunction with accompanying drawing.

[0011] see figure 1 , the anti-vibration cutting tool of the present invention comprises a cutter body 1, a blade 2 and a fastener 3, said cutter body 1 is provided with at least one set of chip flutes 5 and a knife flute, and said cutter body 1 is fastened Part 3 fixes the blade 2 in the sipe, the sipe is composed of the side of the sipe and the bottom of the sipe, the side of the sipe is provided with concave serrations 7, and the side is provided with convex serrations 6, each convex serration 6 are respectively placed in the corresponding concave saw teeth 7, and the cutter body 1 and the blade 2 are composed of the following components by weight: C: 15-18 parts, Mn: 7-8 parts, Si: 1-2 parts, Ni : 1-2.5 parts, Ti: 3-5 parts, rare earth: 5-9 parts, N: 2-5 parts, and the rest are Fe and unremovable impurities. and the side of the lower bottom surface, a side pre-tighten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com