Electrically actuatable drive unit

A driving unit and electric operation technology, applied in the direction of electric components, brakes, electromechanical devices, etc., can solve problems such as inaccuracy, brake pressure adjustment influence, error, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

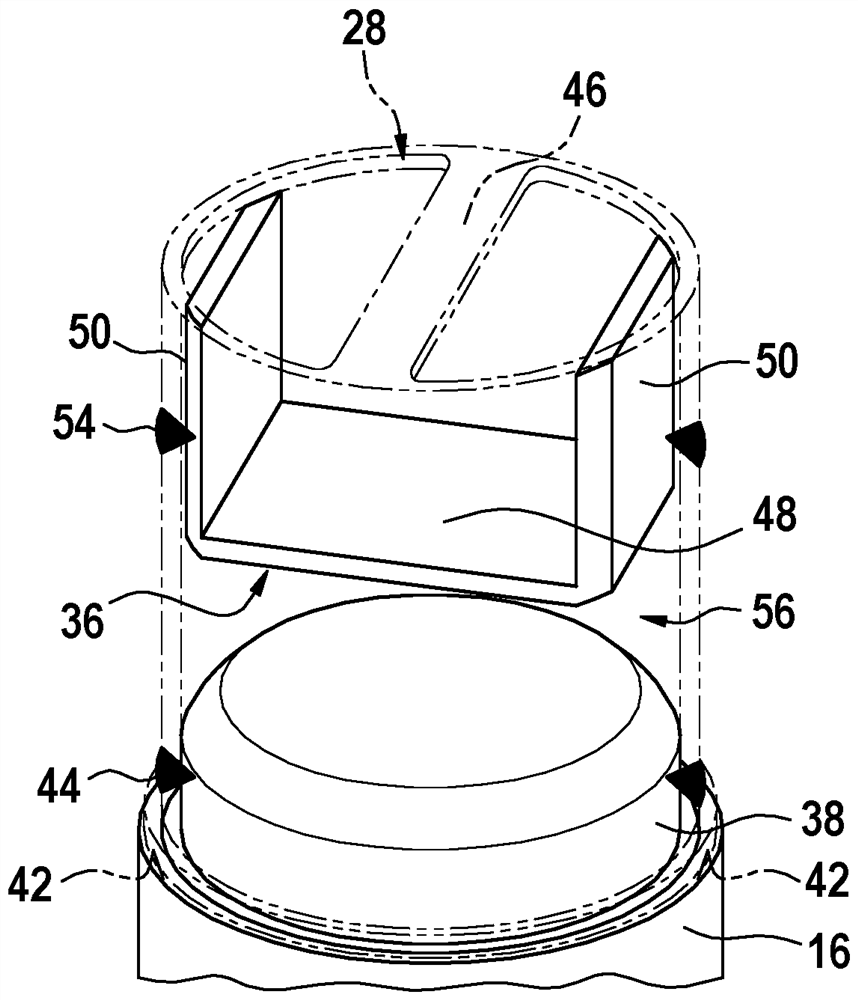

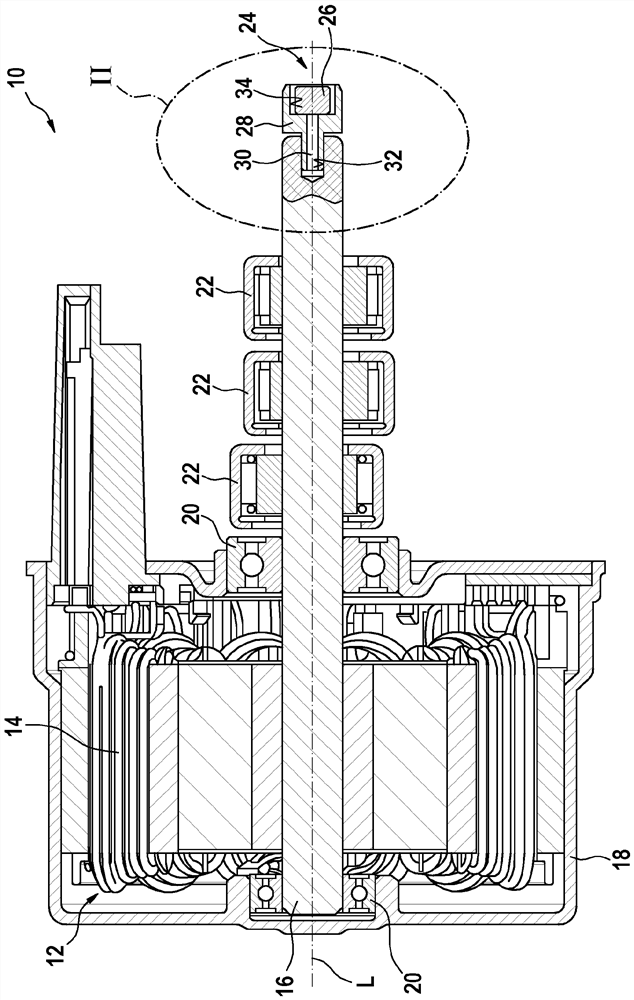

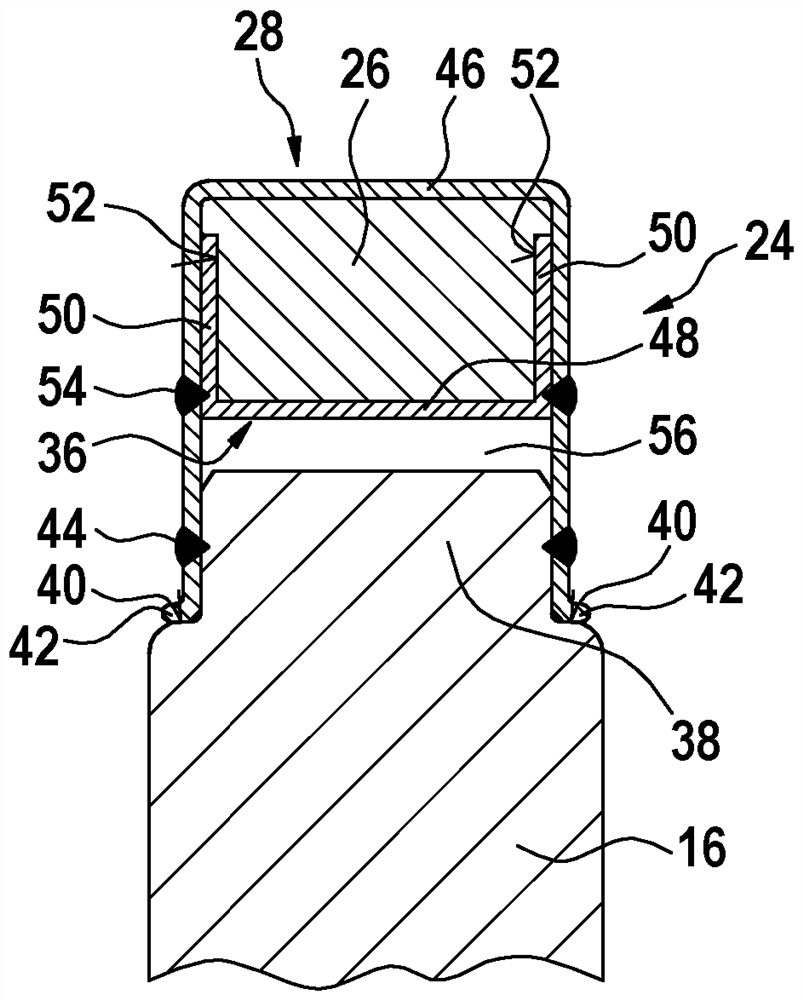

[0021] figure 2 According to the design according to the invention, according to figure 1 Details of X. The motor shaft 16 of the drive assembly 10 is shown in the region of the end of the motor shaft facing away from the rotor 14 of the electric motor 12 (not shown). according to figure 2 , this end of the motor shaft 16 is equipped with a signal transmitter 24 of the sensor device.

[0022] The signal transmitter 24 includes, as is known, a magnetic element 26 which is fastened on the front side of the motor shaft 16 by means of a holding element 28 made of a magnetically non-conductive material. According to the invention, the holding element 28 is produced as a hollow cylinder, within which the magnetic element 26 is accommodated and fixedly anchored by means of a clip element 36 . The hollow cylinder has an open first end with which it is pushed onto a shoulder 38 which is displaced in its outer diameter relative to the outer diameter of the motor shaft 16 . The tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com