Layered eel roasting device

A grilled eel, layered technology, applied in roaster/barbecue grids, kitchen utensils, food processing and other directions, can solve problems such as inability to utilize heat well, different texture and taste of grilled eel, affecting eating quality, etc. Achieve the effect of accelerating grease dripping, increasing speed and reducing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

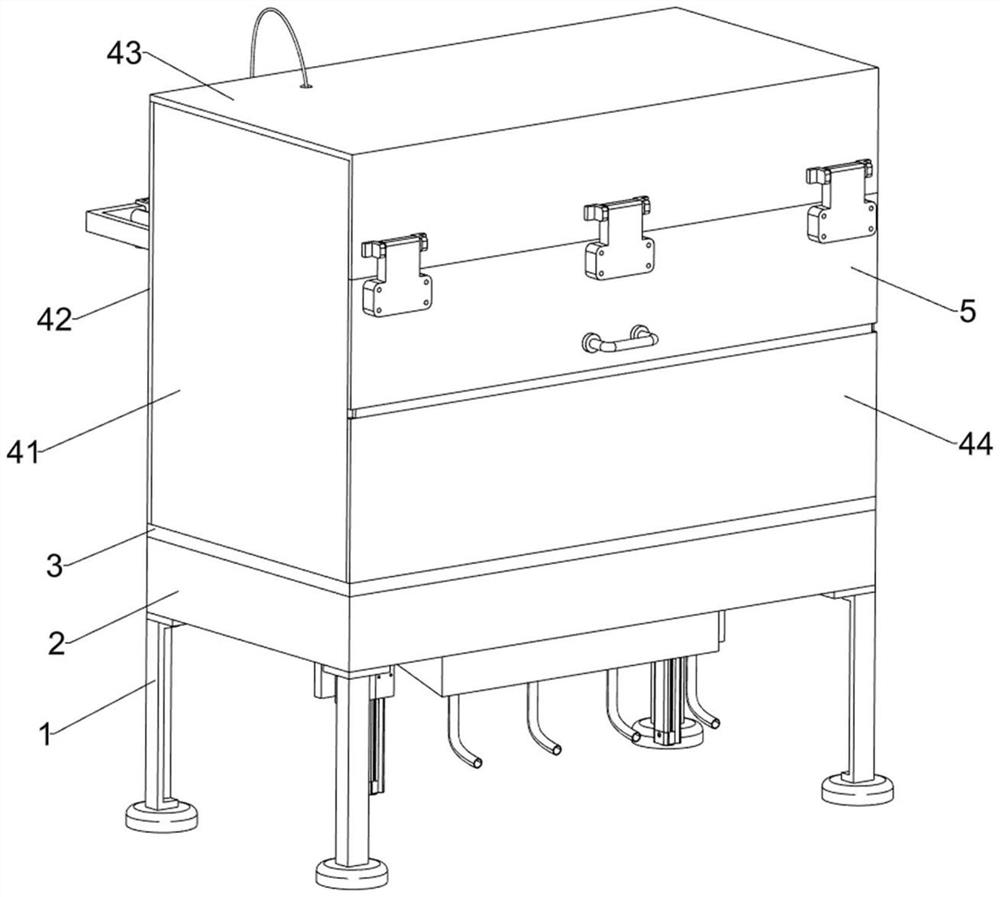

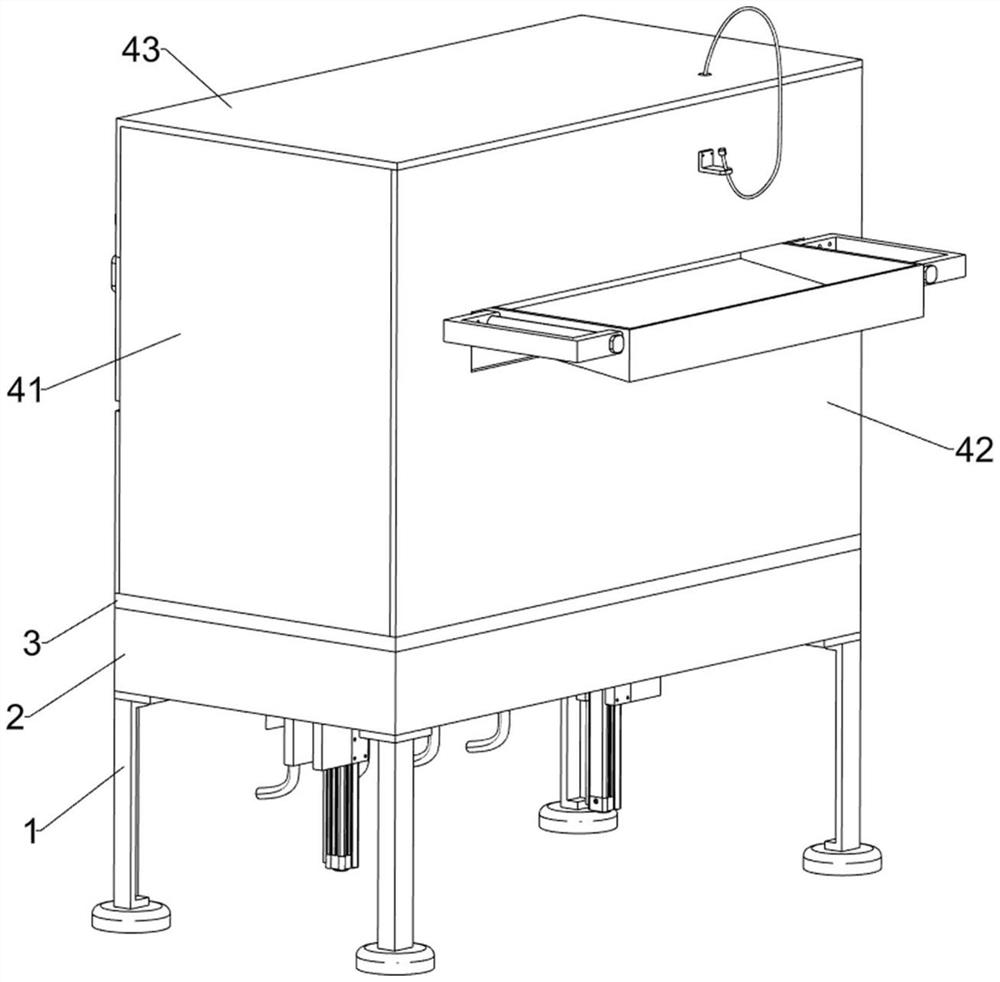

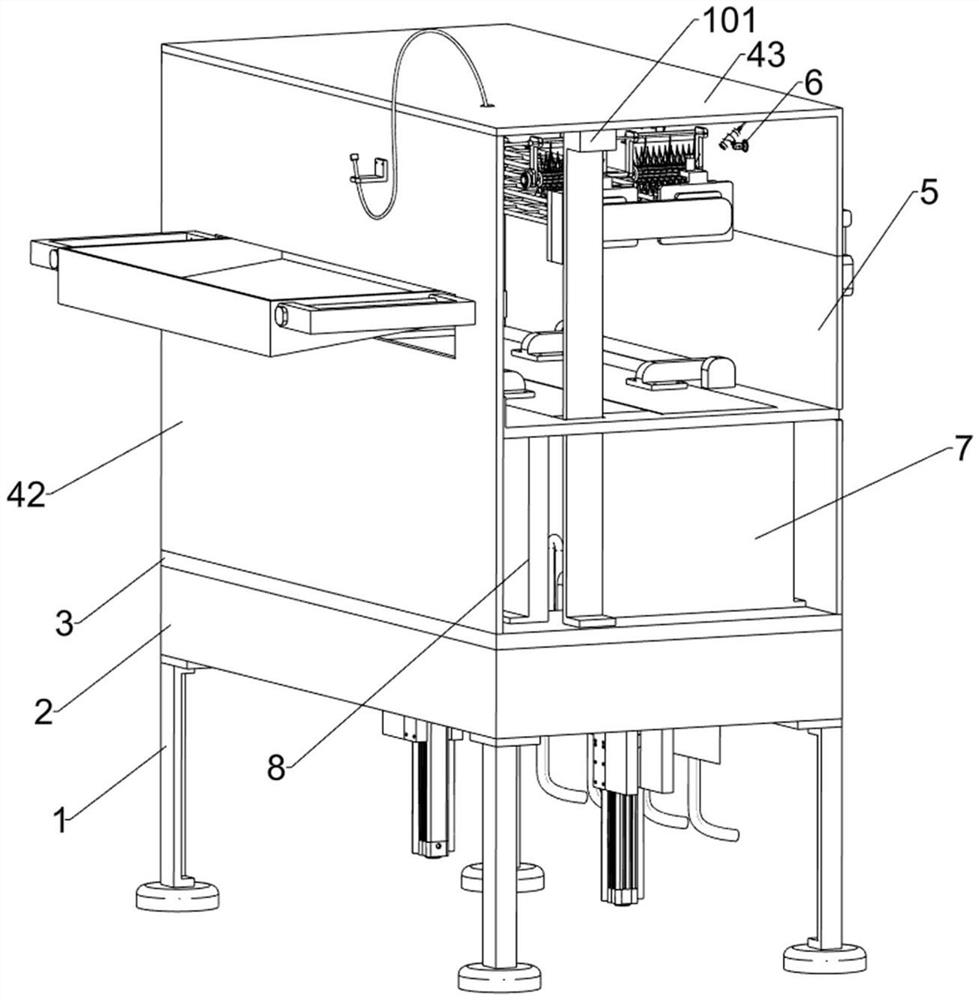

[0034] A layered grilled eel device, such as Figure 1-13As shown, it includes a tripod 1, a carrying frame 2, a first support plate 3, a first side mounting plate 41, a second side mounting plate 42, a top plate 43, an insulating plate 44, a feeding door 5, a camera 6, and a rotating clamp Holding system, baking system and spread sauce system; four tripods 1 are provided, and the upper surface of the four tripods 1 is fixed with a bearing frame 2; the upper surface of the bearing frame 2 is fixed with a first support plate 3; the first support A first side mounting plate 41 is fixed on the left and right parts of the upper surface of the plate 3; a second side mounting plate 42 is fixed on the rear part of the upper surface of the first support plate 3; The isolation plate 44 is connected; the second side mounting plate 42 is fixedly connected to the two first side mounting plates 41; the top plate 43 is fixedly connected between the upper surfaces of the two first side mount...

Embodiment 2

[0042] On the basis of Example 1, as Figure 1-Figure 13 As shown, the spreading system includes a second electric sliding rail 401, a second electric sliding block 402, an L-shaped plate 403, a second electric push rod 404, a first fixing frame 405, a spreader 406, a material distribution pipe 407, The material guide pipe 408, the third support frame 409, the connecting head 4010 and the micro motor 4011; the upper part of the front side of the second side mounting plate 42 is bolted with a second electric sliding rail 401; the second electric sliding rail 401 is slidably connected with a second electric sliding rail 401 Electric slider 402; L-shaped plate 403 is fixed on the second electric slider 402; two second electric push rods 404 are fixed on the L-shaped plate 403; A first fixing frame 405 is connected; each first fixing frame 405 is rotatably connected with a wiper 406; two wipers 406 are fixedly connected; The material guide pipe 408 is connected with a plurality o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com