Copper casting cutting machining lathe

A cutting and casting technology, applied in metal processing equipment, metal processing machinery parts, machine tools suitable for grinding the edge of workpieces, etc., can solve the problems of inaccurate cutting length, high temperature, and existence of errors, so as to avoid inefficiency , high degree of automation, and the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

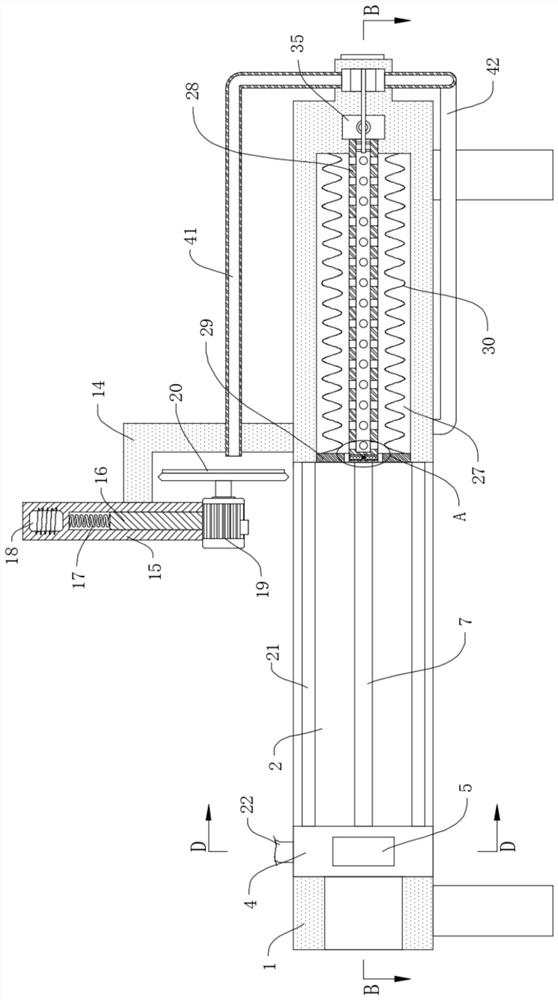

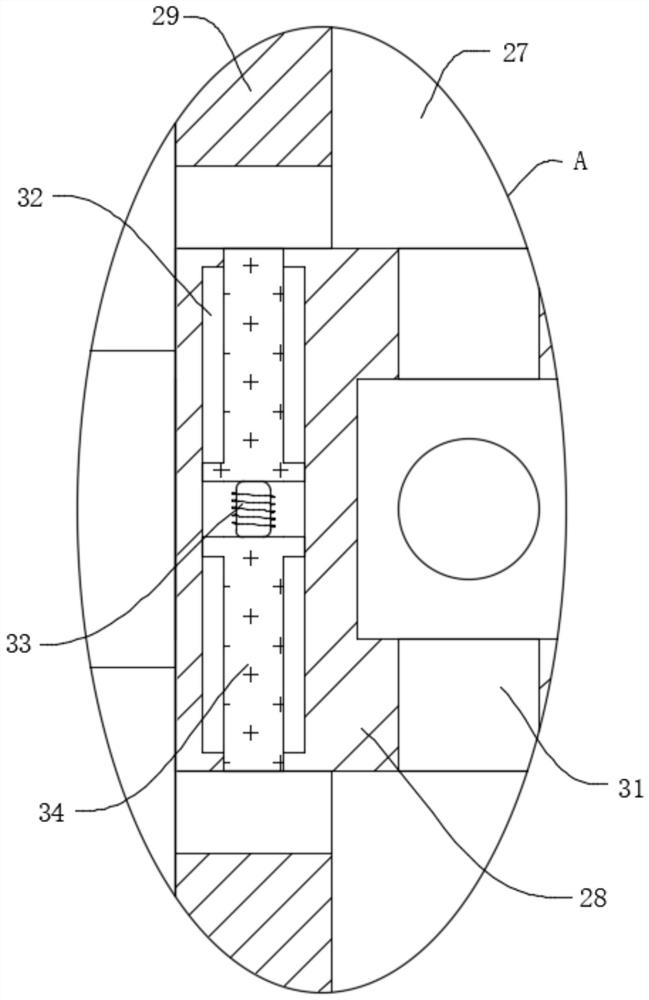

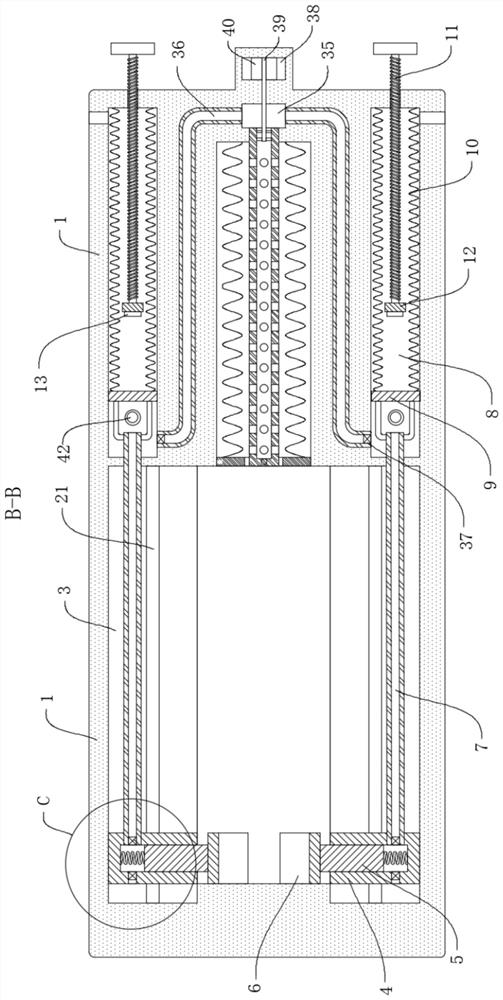

[0027] refer to Figure 1-5 , a lathe for cutting and processing copper castings, comprising a bed body 1, the bed body 1 is provided with a mounting hole 2, the two inner side walls opposite to the mounting hole 2 are provided with sliding grooves 3, and the bed body 1 is provided with a fixed-length cutting mechanism;

[0028] The fixed-length cutting mechanism includes two sliding grooves 3 and two air storage cavities 8 opened in the bed body 1. A first sliding sleeve 4 is slidably connected in the sliding groove 3, and a first sliding sleeve 4 is sealed and slidably connected in the first sliding sleeve 4. The slider 5, a third spring 23 is fixedly connected between the first slider 5 and the first sliding sleeve 4, a sliding tube 7 is fixedly connected through the side wall of the first sliding sleeve 4, and the sliding tube 7 and the bed body 1 pass through sealing and sliding It is connected and extended into the corresponding air storage cavity 8, the sliding tube 7 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com