3D printing nozzle and 3D printer

A 3D printing and nozzle technology, applied in the field of additive manufacturing, can solve the problems of affecting the quality of printed products, unable to prevent the outflow of raw materials, and unable to meet the requirements of 3D particle printing, etc., to achieve energy saving, good leak-proof effect, and simple control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

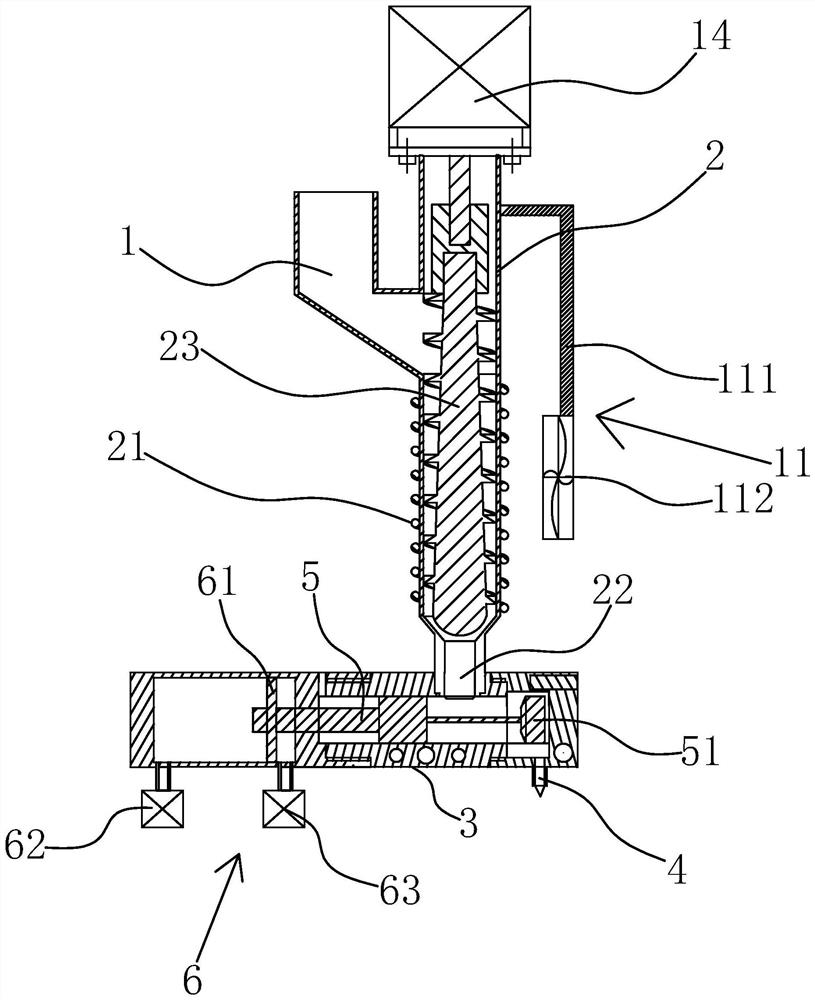

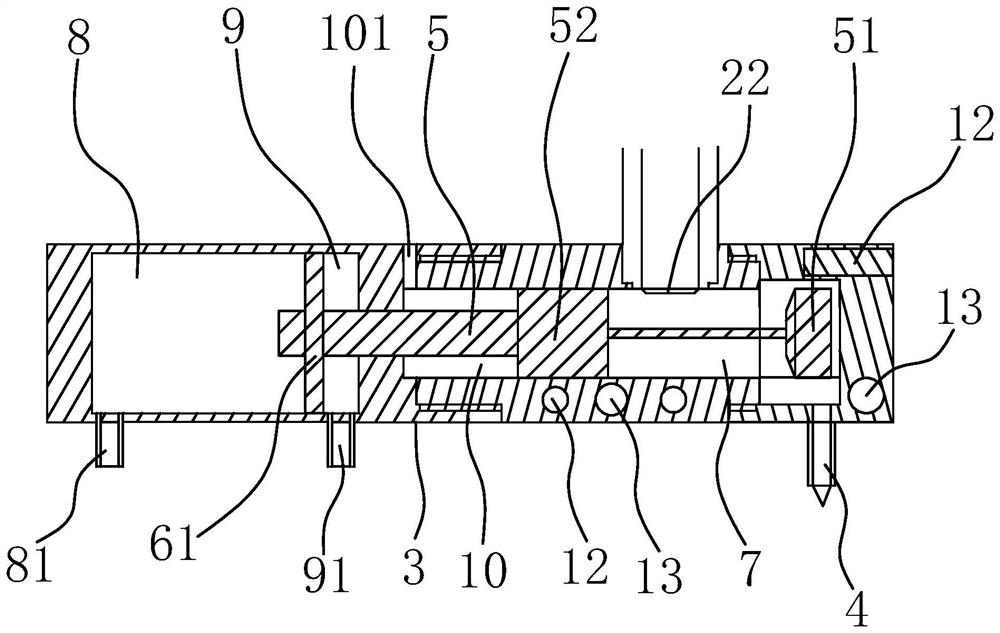

[0026] The following are specific embodiments of the present invention and the accompanying drawings to further describe the technical solutions of the present invention, but the present invention is not limited to these embodiments.

[0027] like Figure 1-2 As shown, the present invention includes a feeding port 1, a feeding pipe 2, a discharging pipe 3, and a nozzle 4, including a feeding port, a feeding pipe, a discharging pipe, and a nozzle, and the discharging pipe is provided with an axially movable The movable shaft and the driving device that can drive the movable shaft to move axially, the movable shaft is provided with a material blocking part, and the end of the feeding pipe 2 is provided with a through hole 22 that communicates with the discharging pipe 3. The movable shaft 5 is also provided with a pressure regulating piston 52 that fits with the inner wall of the discharge pipe 3. A discharge channel 7 is formed between the pressure regulating piston 52, the mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com