Novel carbon tank structure meeting requirements of complex vehicle body

A new type of technology for the body, applied to the charging system, adding non-fuel substances to the fuel, and the combustion engine. It can solve the problems of increasing the difficulty of disassembling and assembling the carbon tank structure, short oil vapor flow path, and harsh boundaries of the body. The effect of blocking the risk of fine particles of carbon powder entering the adsorption port, extending the length of the total flow path, and easy and accurate installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

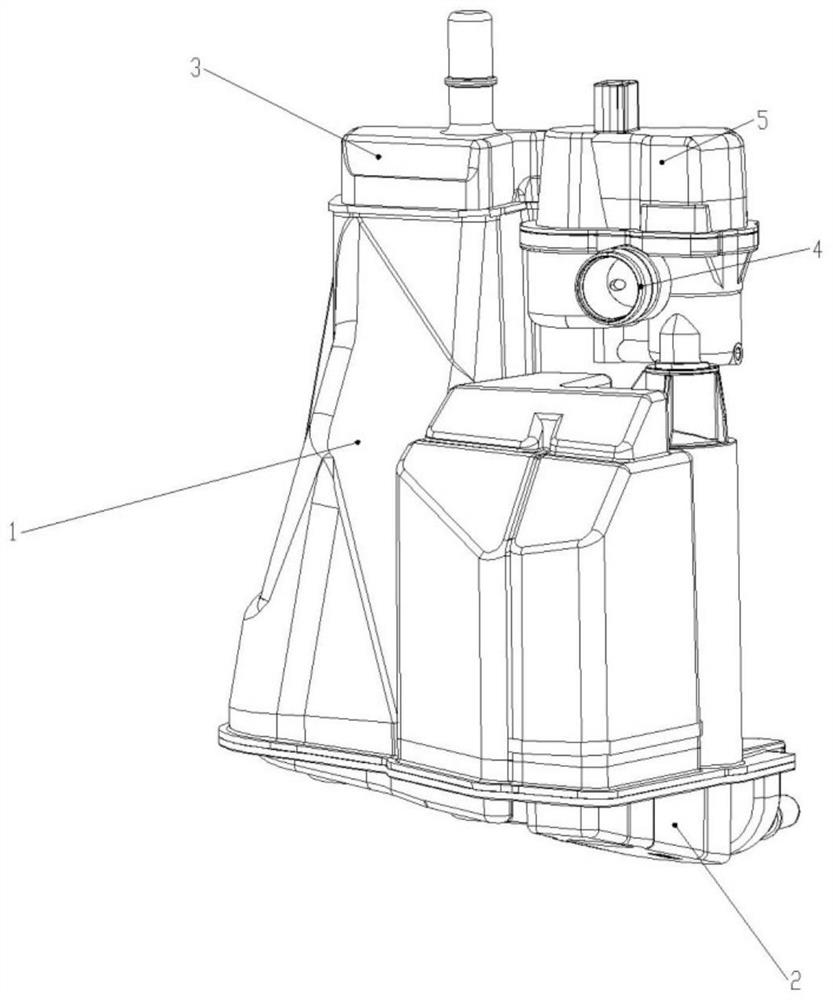

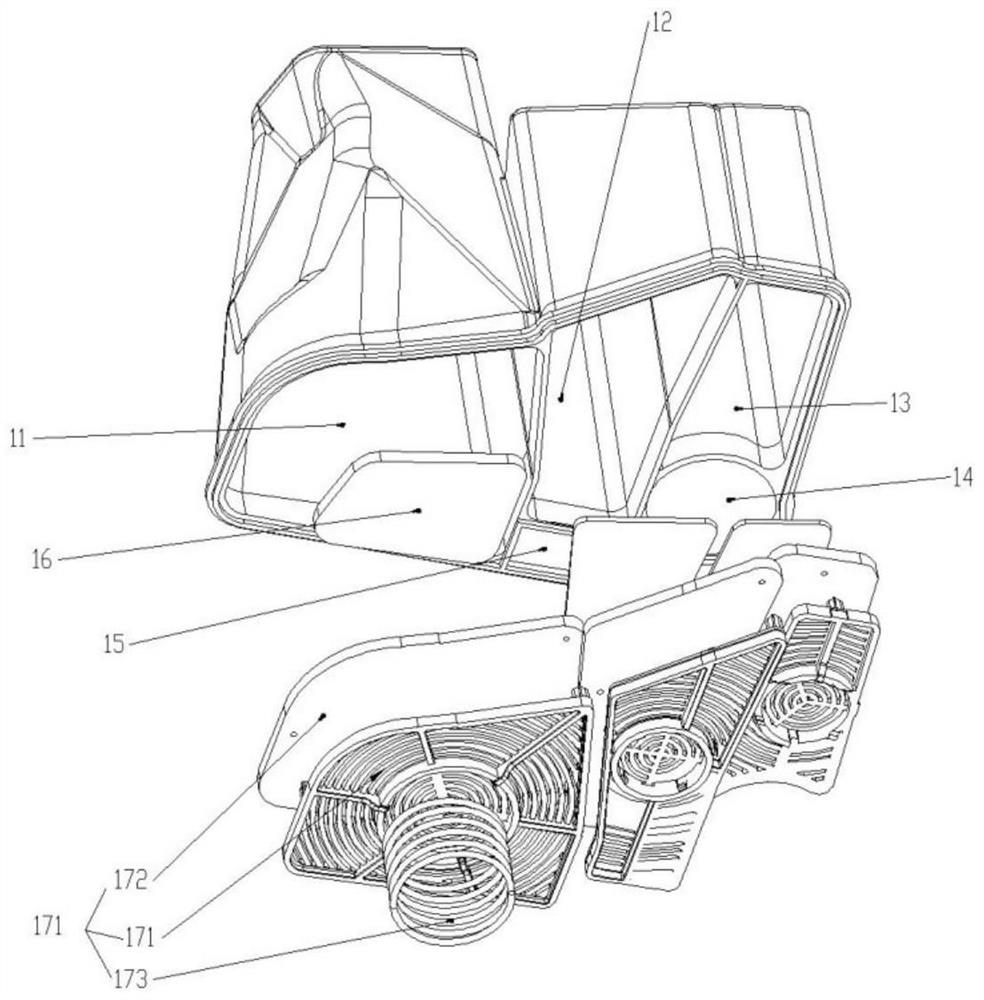

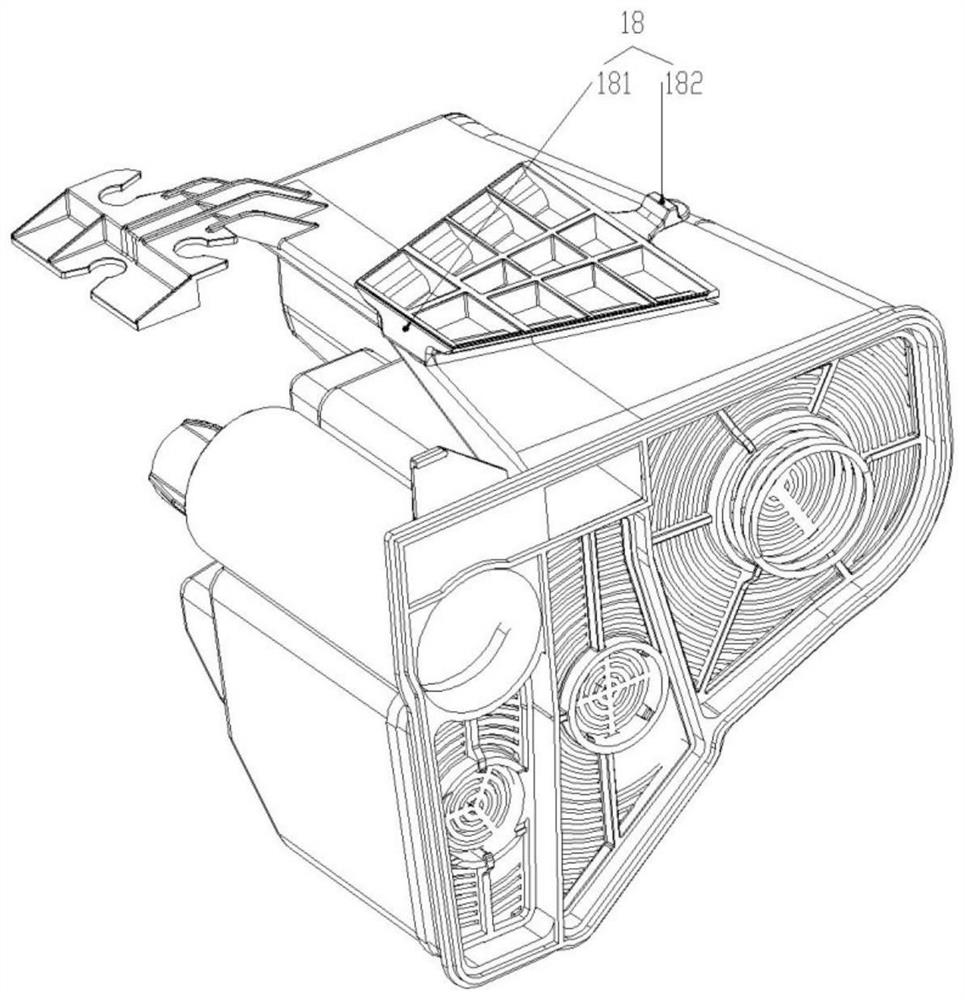

[0025] like figure 1Shown is a perspective view of the present invention, including a casing 1, a bottom cover 2, an adsorption port structure 3, an air outlet structure 4, and a leakage diagnosis module 5. The bottom cover 2 is arranged below the casing 1, and the adsorption port structure 3 Disposed above the casing 1, the air outlet structure 4 is disposed on the casing 1 at the side of the adsorption port structure 3, and the leakage diagnosis module 5 is disposed above the air outlet structure 4; figure 2 and as image 3 Shown are an exploded perspective view of the housing 1 and perspective views from different perspectives, in which a first cavity 11, a second cavity 12, a third cavity 13, a fourth cavity 14, and a flow channel 15 are arranged side by side. The upper positions of the second cavity 12 and the third cavity 13 communicate with each other.

[0026] The type of toner in the first cavity 11 and the second cavity 12 is Bax1500; the type of toner in the thir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com