Noise testing method for air-cooled variable-frequency refrigerator

A technology of noise testing and frequency conversion refrigerators, which is applied in the direction of household refrigerators, refrigerators, coolers, etc., can solve the problems of not establishing a unified detection, not in the test range, and high noise complaints, and achieve high market application value and good noise matching effect, the effect of avoiding interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

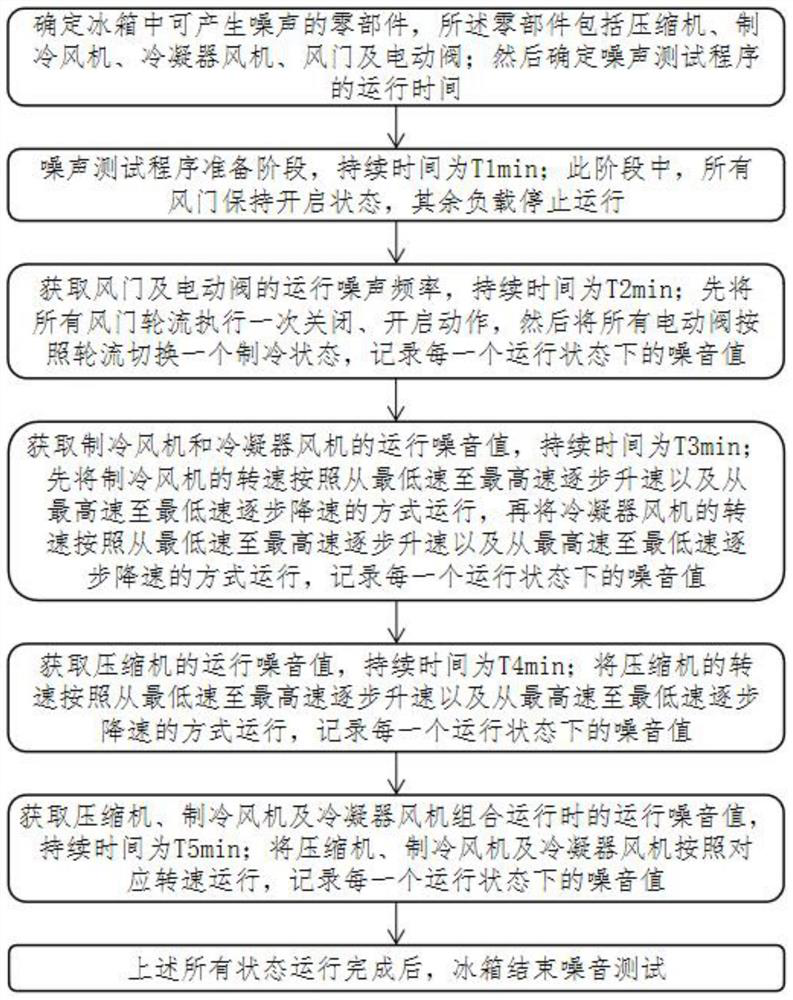

[0025] see figure 1 As shown, the present invention is a noise testing method for an air-cooled inverter refrigerator, comprising the following steps:

[0026] Step 1: Determine the parts that can generate noise in the refrigerator, the parts include compressor, refrigeration fan, condenser fan, damper and electric valve, and the damper includes refrigerating damper and variable temperature damper; then determine the running time of the noise test program ;

[0027] Step 2, the preparation stage of the noise test program, with a duration of 2 minutes; in this stage, all dampers are kept open, and other loads such as inverter compressors, refrigeration fans, condenser fans and electric valves are stopped;

[0028] Step 3: Obtain the operating noise frequency of the damper and the electric valve, and the duration is 3 minutes; first, all dampers are closed and opened in turn, that is, the closing time of the refrigerating damper is 40s → the opening time of the refrigerating da...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com