Light emitting diode module with high durability and manufacturing method thereof

A technology of light emitting diodes and manufacturing methods, applied in the manufacture of light emitting diode modules, in the field of light emitting diode modules with high durability, can solve high maintenance costs, durability and reliability of light emitting diode lighting modules need to be further improved, and improve light emitting diodes Lighting module maintenance costs and other issues to achieve the best durability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

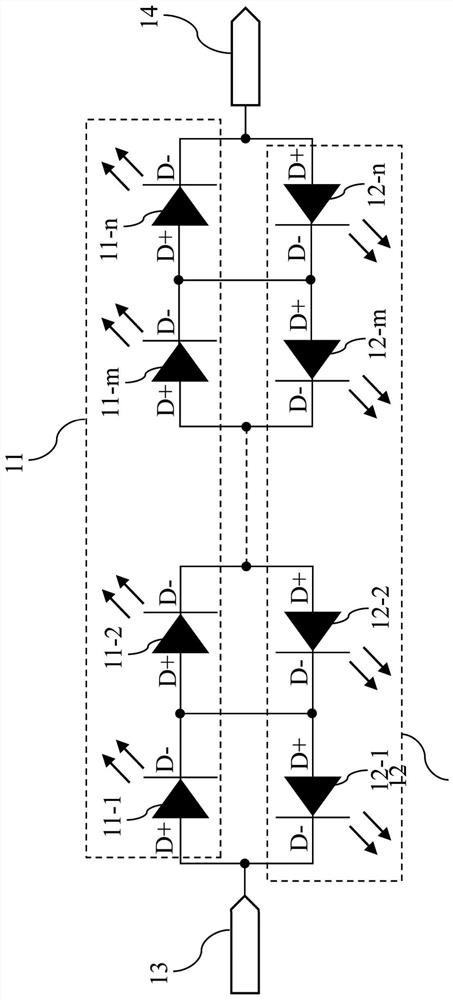

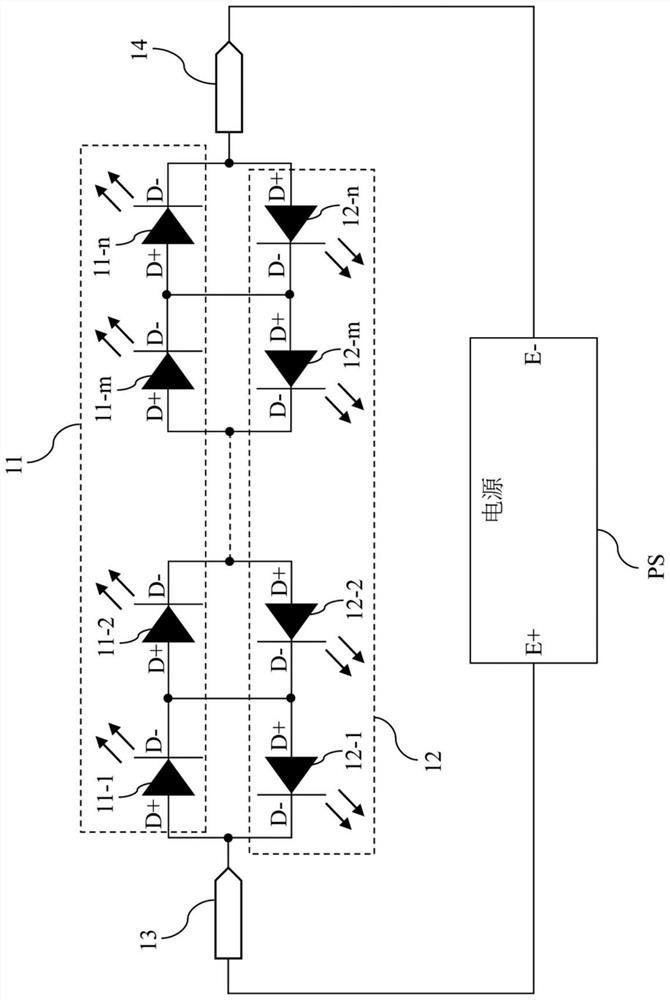

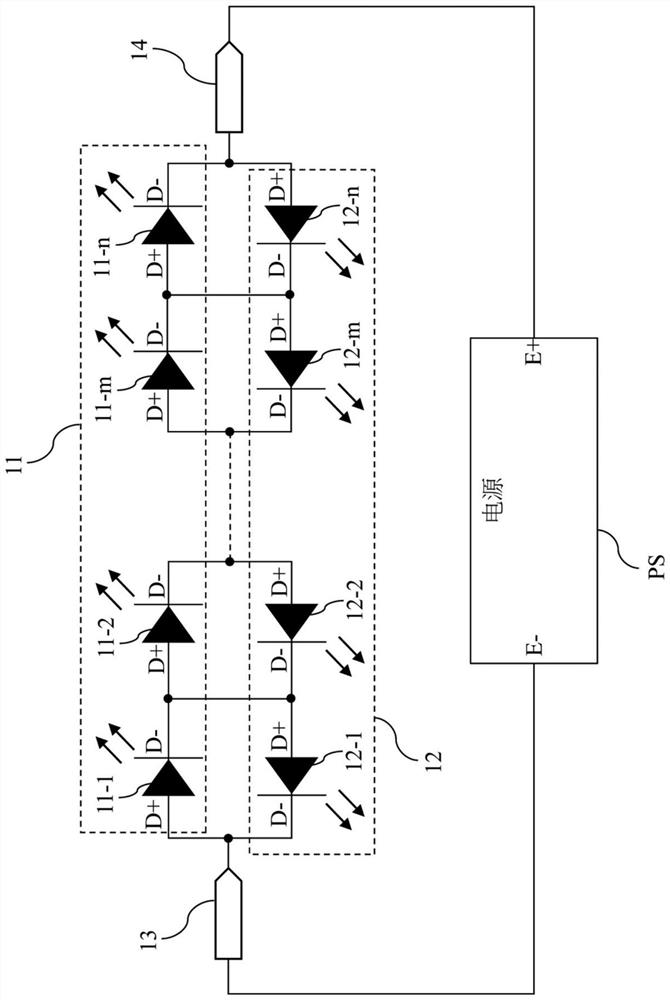

[0027] Embodiments of the high-durability light emitting diode module and the method for manufacturing the same according to the present invention will be described below with reference to the related drawings. For the sake of clarity and convenience in the description of the drawings, the dimensions and proportions of the components in the drawings may be changed. Presented exaggerated or reduced. In the following description and / or claims, when an element is referred to as being "connected" or "coupled" to another element, it can be directly connected or coupled to the other element or intervening elements may be present; When "directly connected" or "directly coupled" to another component, there are no intervening components, and other words used to describe the relationship between components or layers should be interpreted in the same manner. For ease of understanding, the same components in the following embodiments are denoted by the same symbols.

[0028] see figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com