Auxiliary support for wood board color fading treatment

A technology of auxiliary brackets and boards, applied in the direction of wood processing, wood processing details, wood processing appliances, etc., can solve problems such as affecting the quality of finished products, poor overall floor effect, unacceptable to consumers, etc., to improve efficiency and quality of finished products, guaranteeing Uniformity, ease of use and manipulation for flexible results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049]In order to make those skilled in the art better understand the technical solutions of the present invention, the present invention will be further described in detail below with reference to the accompanying drawings.

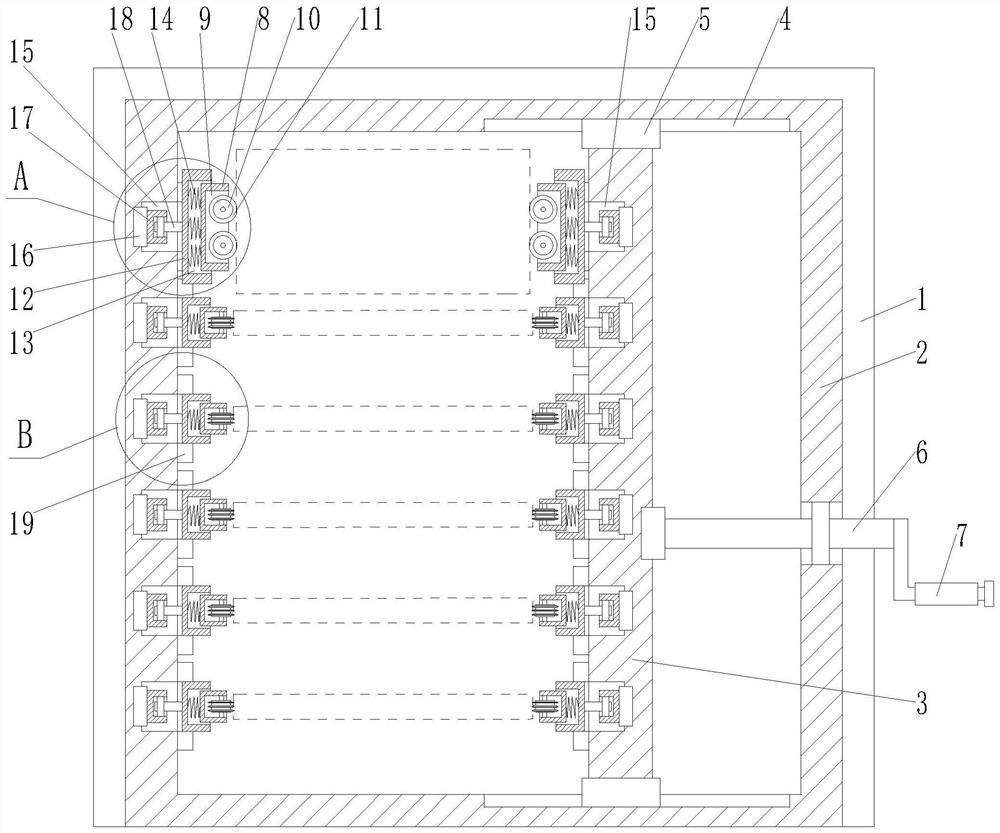

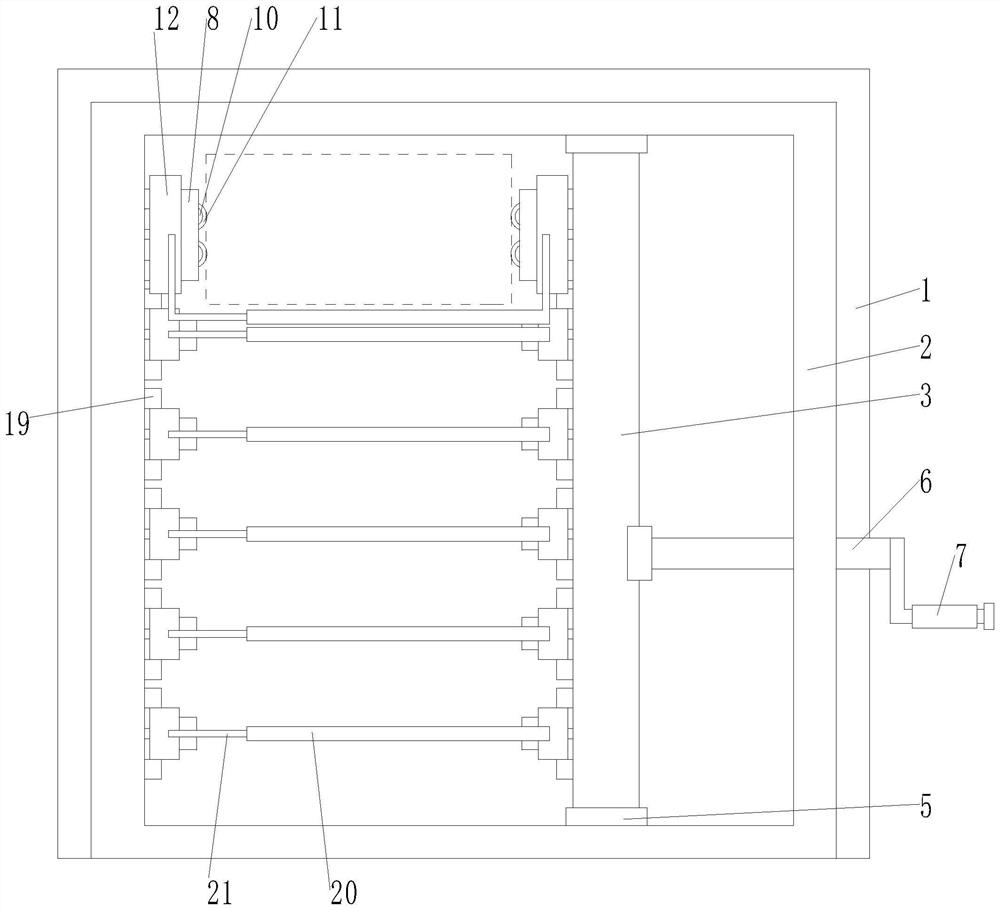

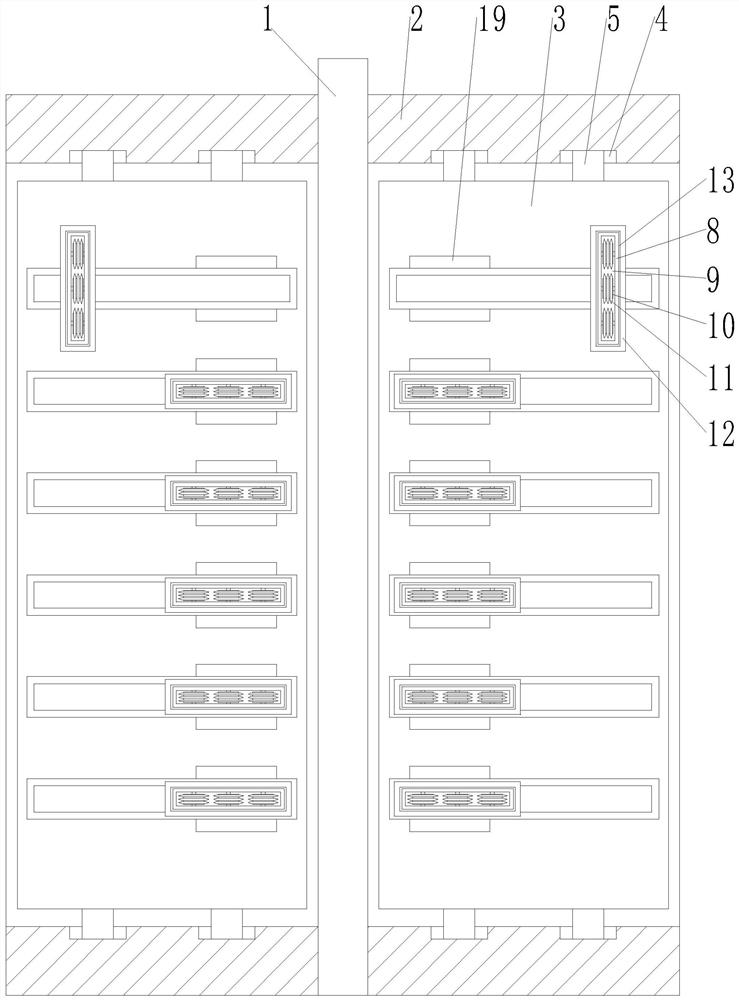

[0050] see Figure 1-5 , an auxiliary support for wood fading treatment, comprising:

[0051] The external support frame, which supports and assembles the overall structure of the device, and also protects the supported wooden boards;

[0052] A clamping and fixing mechanism, which is rotatably arranged on the external support frame and fixes the wooden board by clamping both ends of the wooden board. The clamping and fixing mechanism at least includes two sets of clamping single arms with the same structure and symmetrical arrangement, and two sets of clamping arms. The single-arm resultant force clamps the two ends of the wooden board to fix the wooden board; wherein, in the case where the two ends of the wooden board are clamped by the two sets of cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com