Drain valve assembly and washing machine

A drainage valve and component technology, applied in the field of washing machines, can solve the problems of reduced drainage efficiency, limited centrifugal force of centrifugal block, unsatisfactory sealing effect, etc., and achieve the effect of flexible installation position, saving installation space and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

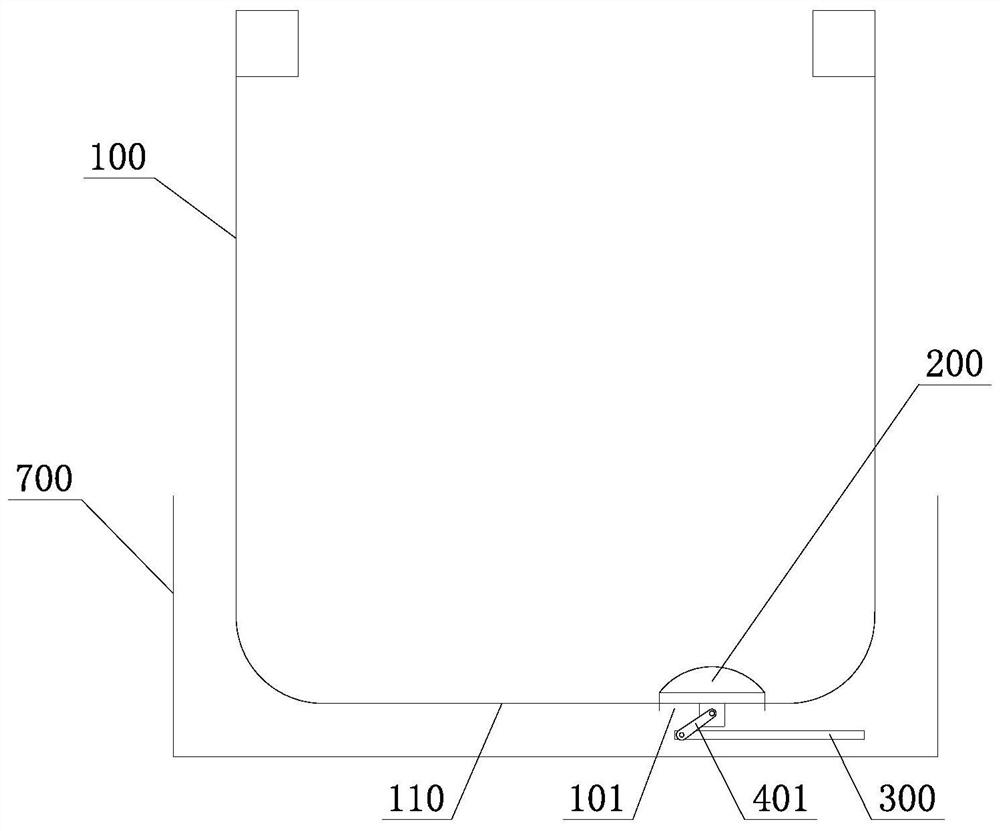

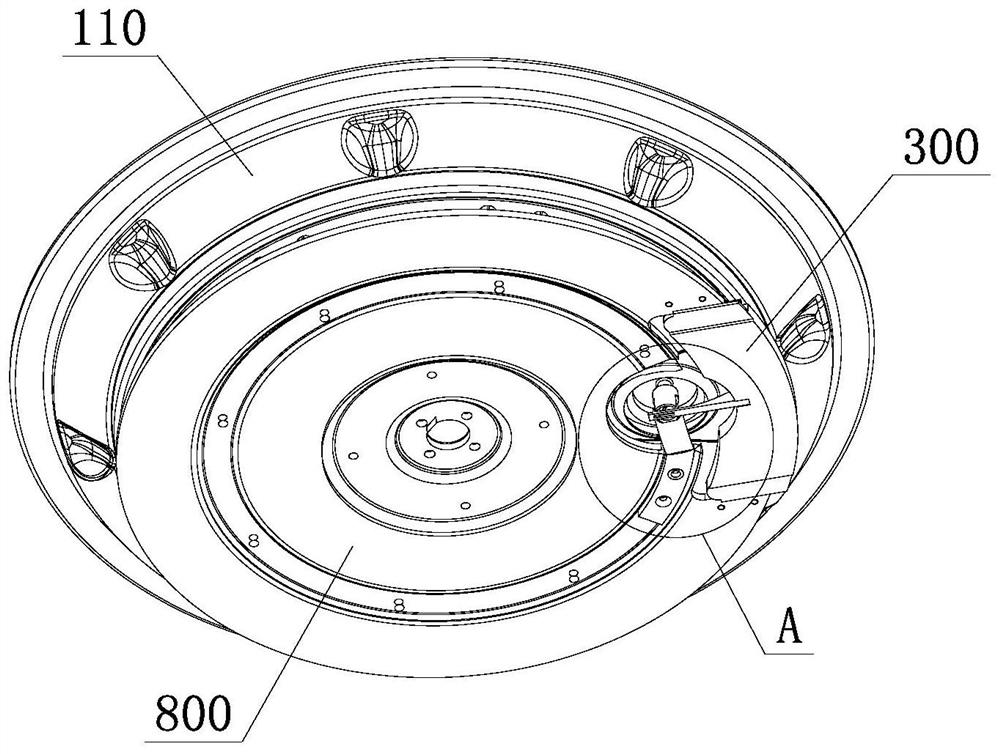

[0056] like Figure 1 to Figure 10 As shown, the drain valve assembly described in this embodiment includes a valve plug 200 and a driving component for driving the valve plug 200 to move. The driving component includes a centrifugal slider 300 and a reversing transmission mechanism, the reversing transmission mechanism is respectively connected with the centrifugal The slider 300 is connected to the valve plug 200 . The centrifugal slider 300 slides under the action of centrifugal force, and drives the valve plug 200 to move through the reversing transmission mechanism. The sliding direction of the centrifugal slider 300 is different from the moving direction of the valve plug 200 .

[0057] In the above solution, the centrifugal slider 300 and the valve plug 200 can move in different directions by setting the reversing transmission mechanism. The drain valve assembly of this embodiment can be applied to a washing machine for centrifugal drainage, such as figure 1 and fi...

Embodiment 2

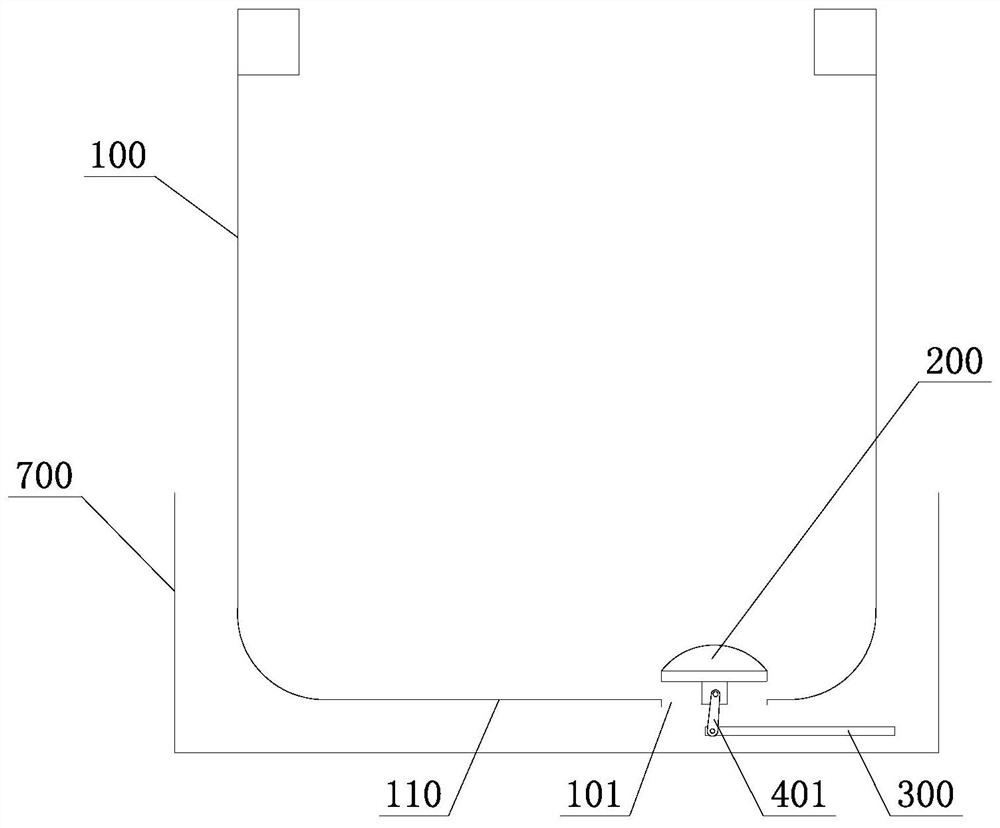

[0095] like Figure 11 and Figure 12 As shown, the difference between this embodiment and the above-mentioned first embodiment is that: the first end 4011 of the reversing rod 401 is set lower than the second end 4012, the centrifugal slider 300 slides horizontally under the action of centrifugal force, and the reversing rod 401 is The centrifugal slider 300 is driven to swing downward, and the valve plug 200 is pulled to move downward.

[0096] In the above solution, when the drain valve assembly is installed on the washing machine, the valve plug 200 is located below the tub bottom 110 of the inner tub 100 to block the drain port 101 from the bottom to the top from the outside of the inner tub 100 . When the inner tub 100 is filled with water, the water pressure at the bottom of the inner tub 100 acts on the sealing cover 201. During the process that the centrifugal slider 300 drives the valve plug 200 to open the water outlet 101, the water pressure at the bottom of the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com