Important equipment independent grounding device and construction method thereof

A grounding device and equipment technology, applied in the direction of connection insulation, connection contact material, clamping/spring connection, etc., can solve the problems of medical equipment, loss of precision equipment, harsh grounding requirements, etc., to achieve safety guarantee, reduce grounding resistance value , The effect of meeting the needs of safety production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described in detail below with reference to the accompanying drawings.

[0039] The embodiment of the present invention discloses an independent grounding device for important equipment.

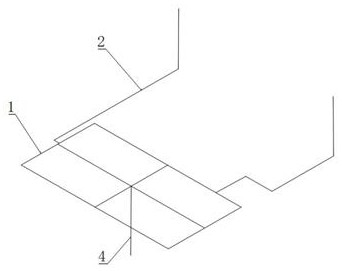

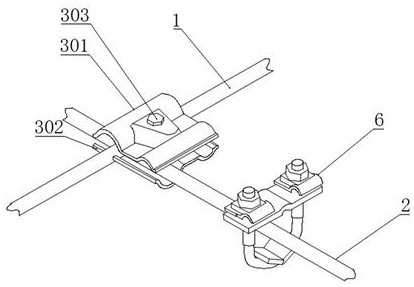

[0040] refer to figure 1 , including a grounding grid 1, a grounding wire 2, a fixture 3 and a grounding electrode 4. The grounding grid 1 includes tinned copper stranded wires arranged vertically and horizontally, and a grid-like structure is formed between the tinned copper stranded wires. The size of the net 1 is 20m×10m, and the cross-sectional area of the copper tinned stranded wire is 115-125mm 2 , the copper tinned stranded wire is 15 to 20 strands, the diameter of each strand is 3 to 10 mm, and the size of each grid is 5 m×10 m.

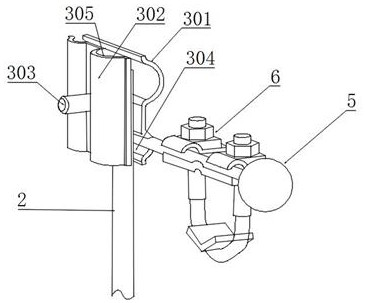

[0041] The copper tinned stranded wires are connected by a clamp 3, the grounding electrode 4 is arranged in the center of the grounding grid 1 perpendicular to the grounding grid 1, the grounding electrode 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cross-sectional area | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com