Single crystal manufacturing system and single crystal manufacturing method

A manufacturing system and manufacturing method technology, applied in the direction of single crystal growth, single crystal growth, chemical instruments and methods, etc., can solve the problems of uneconomical, increased grinding and grinding costs, etc., to prevent calculation errors and prevent setting errors. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

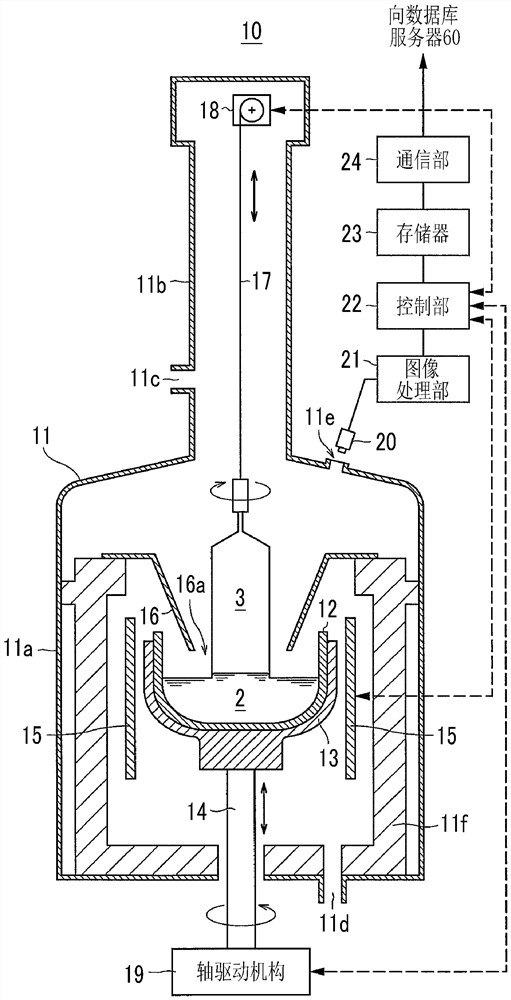

[0030] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

[0031] figure 1 It is a block diagram which shows the whole structure of the single crystal manufacturing system which concerns on embodiment of this invention.

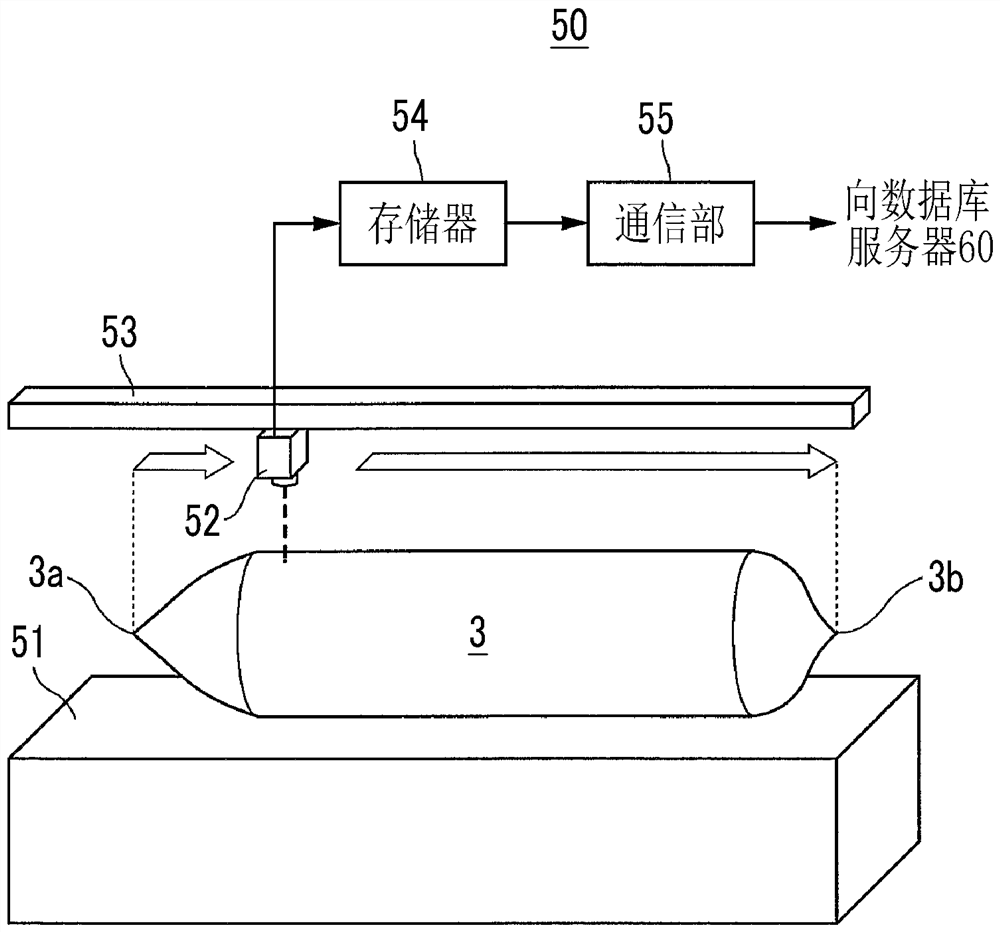

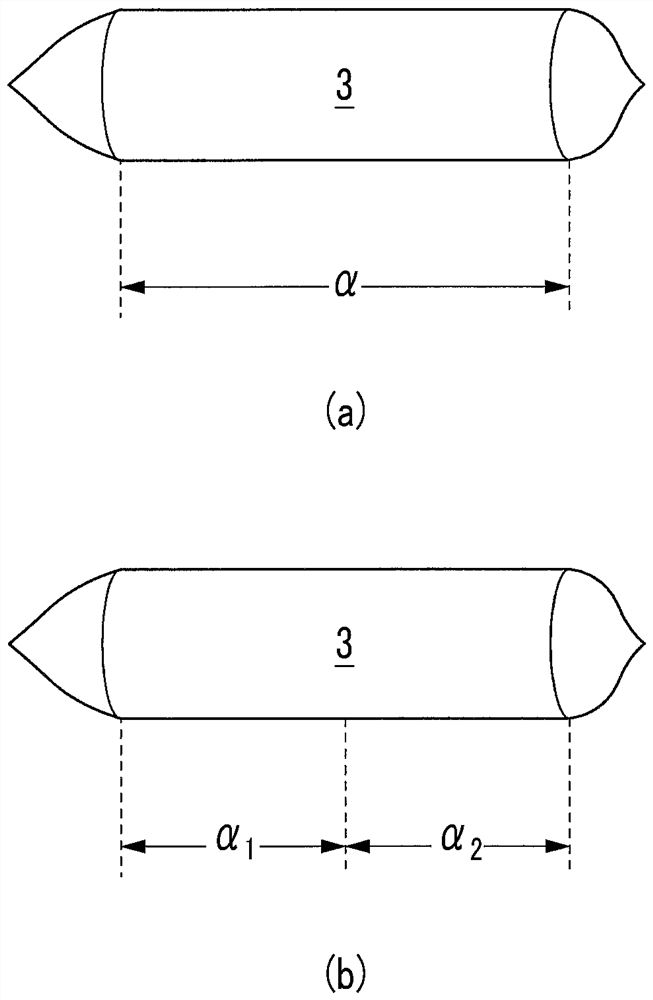

[0032] like figure 1 As shown, the single crystal production system 1 includes: a plurality of single crystal pulling devices 10 for pulling single crystal silicon by the CZ method; and a diameter measuring device 50 for measuring single crystals pulled by the plurality of single crystal pulling devices 10 at room temperature The diameter of the crystalline silicon ingot; the database server 60 manages data related to the single crystalline silicon ingot. The plurality of single crystal pulling apparatuses 10 and diameter measuring apparatuses 50 are connected to the database server 60 via the communication network 70, and are configured to be capable of data communication wi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap