Improved double-spiral-tube-bundle dust and mist eliminator

An improved, mist eliminator technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of insufficient inertial impact force, reduced dust removal and mist removal efficiency, and substandard dust discharge, and achieves resistance to passage. Small size, good dust removal and defogging effect, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

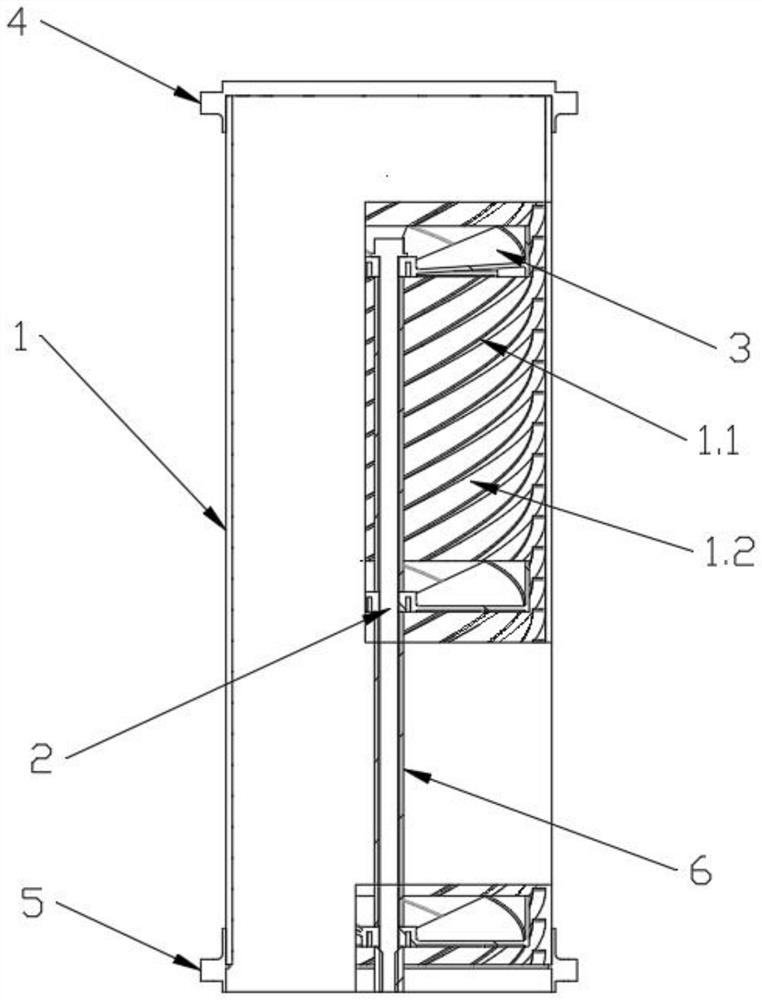

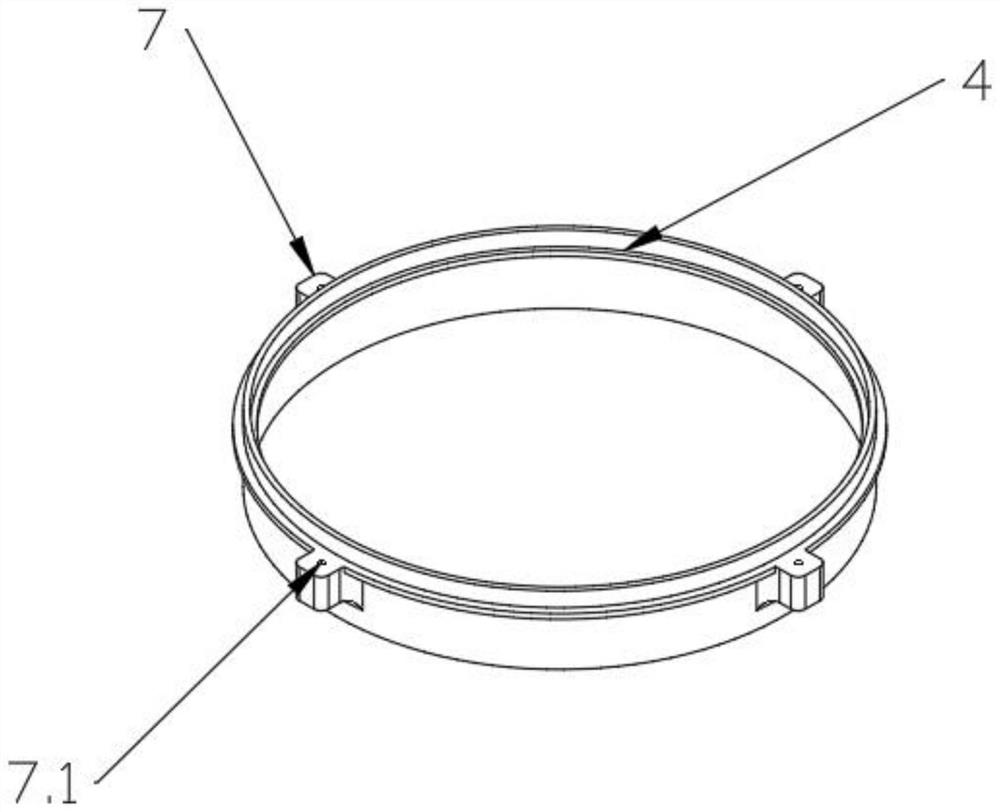

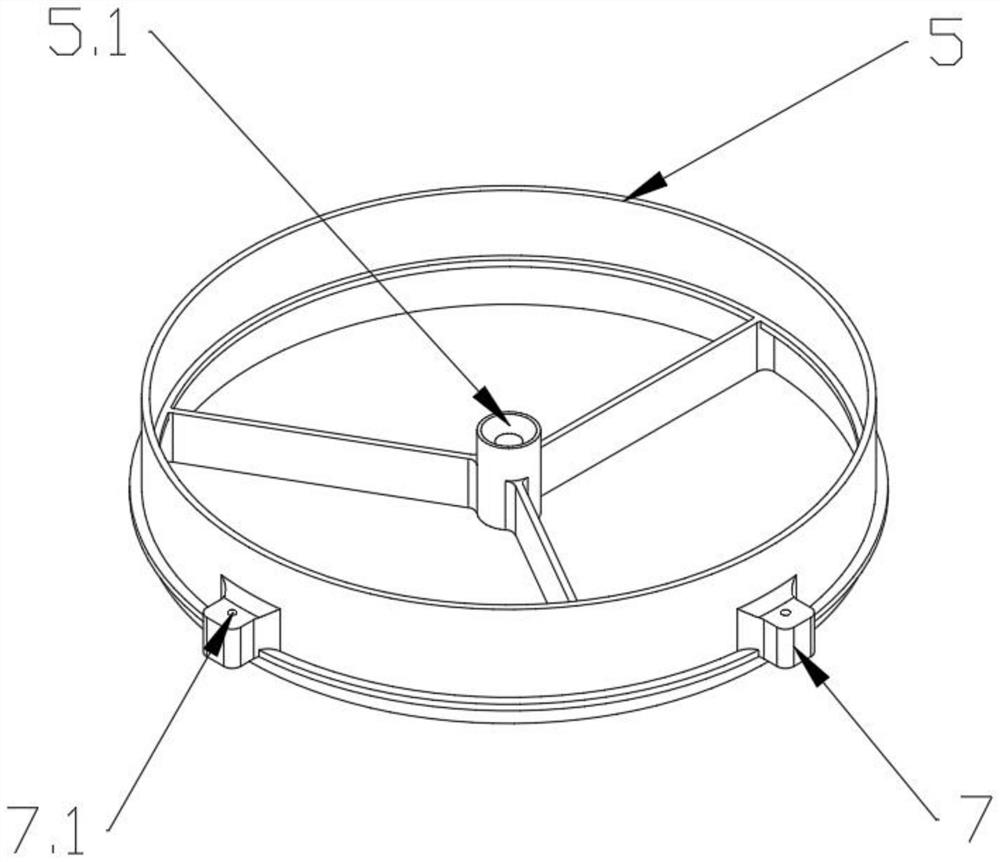

[0019] combined with Figures 1 to 3 , an improved double-coiled tube bundle dust collector, including a barrel 1, a fixed screw 2, and a separator 3. The upper and lower ends of the outer ring of the barrel 1 are respectively provided with an upper base 4 and a lower base that are snap-fitted with it. 5. A fixed screw 2 is arranged coaxially inside the barrel 1, and a separator 3 is arranged on the fixed screw 2 coaxially sleeved. The spacer tube 6 on the screw 2, the upper and lower ends of the barrel 1 are provided with sealing plates that cooperate with it;

[0020] A plurality of spiral ribs 1.1 are arranged on the inner wall of the cylinder body 1, and a water tank 1.2 is arranged between the spiral ribs 1.1;

[0021] The separator 3 is a rotating blade composed of a plurality of blades, and the rotation direction of the separator 3 is opposite to the rotation direction of the spiral rib 1.1.

[0022] As a preferred implementation of this embodiment, the outer rings of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com