Centrifugal three-phase separation and real-time collection device and method for kitchen waste

A kitchen waste and three-phase separation technology, applied in chemical instruments and methods, transportation and packaging, feed, etc., can solve problems such as environmental hazards, unfavorable environmental protection, and environmental damage, so as to avoid environmental pollution, promote value, and save resource effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

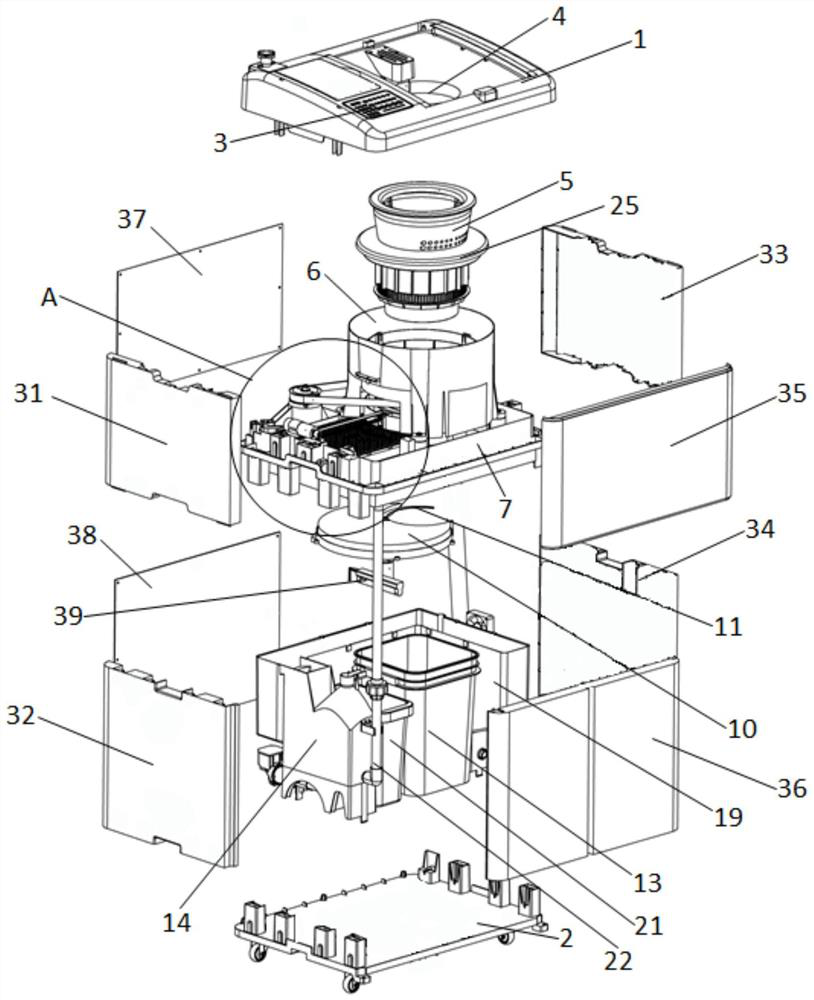

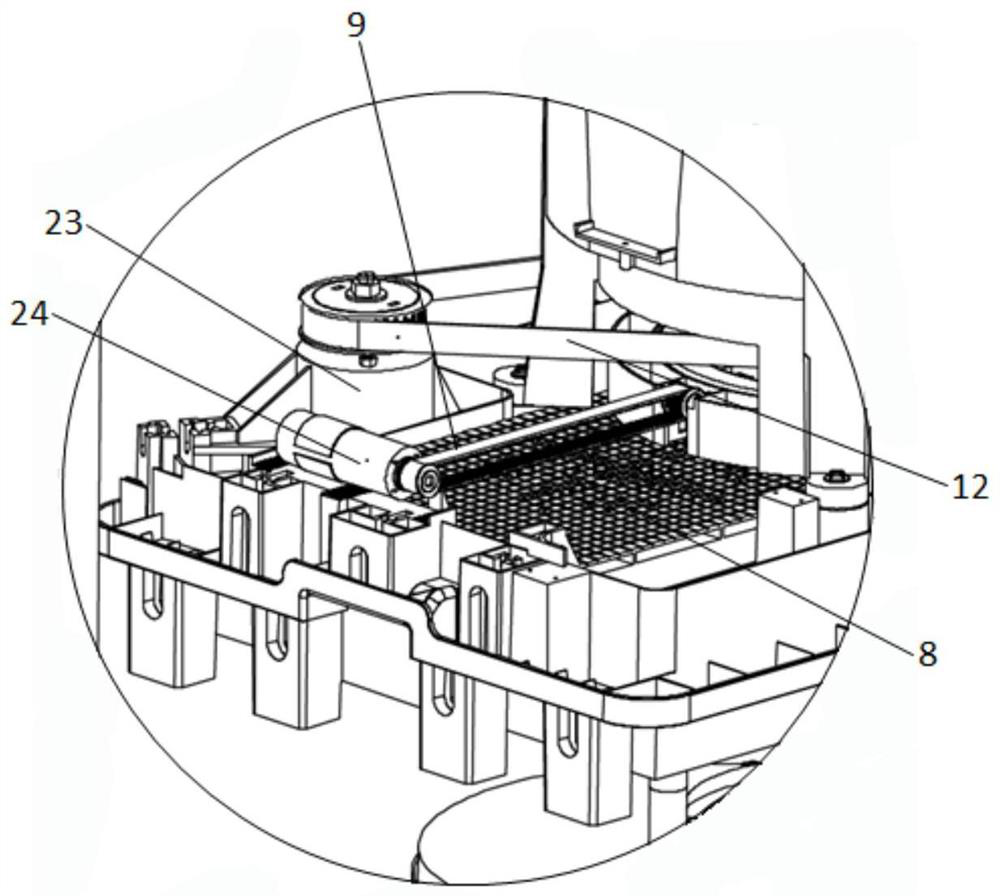

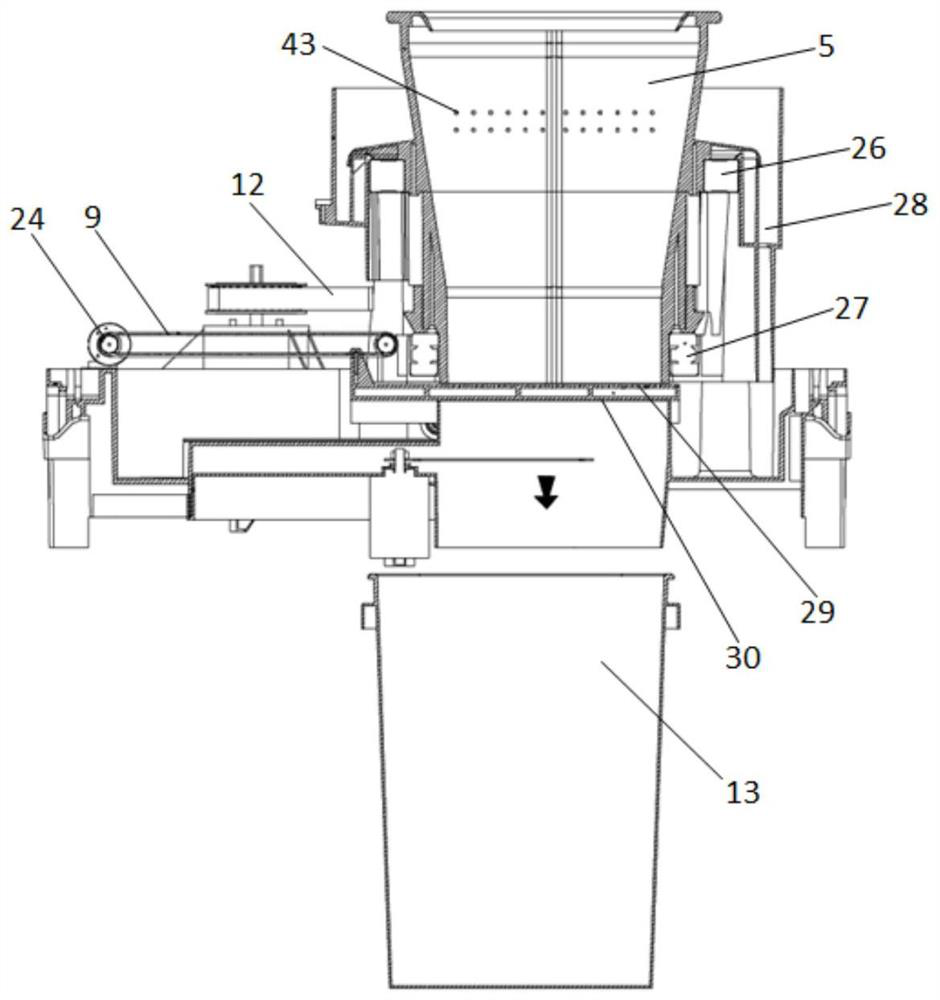

[0039] A centrifugal three-phase separation and collection device for kitchen waste comprises a shell, a solid-liquid separation structure, an oil-water separation structure and a control unit.

[0040] Specifically, the casing: includes a face frame 1, a bottom frame 2 and a side plate, one side of the face frame 1 is provided with an operation panel 3, the other side is provided with a feed port 4, and the lower part of the operation panel 3 is connected with the electric box;

[0041] Further, the side panel includes a left side panel, a front side panel, a right side panel and a rear side panel which are connected in sequence and are perpendicular to each other, and the top and bottom ends of the left side panel, the front side panel, the right side panel and the rear side panel are respectively The left side panel includes an upper left side panel 31 and a lower left side panel 32, the upper left side panel 31 and the lower left side panel 32 are clamped to each other, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com