Self-locking structure of drill chuck

A technology of self-locking structure and drill chuck, which is applied in the direction of tool joints, etc., can solve problems such as failure to work normally, work safety and reliability to be improved, self-locking function failure, etc., to achieve simple and effective buckle mode and operation mode, and improve Effects of operational reliability, ease of manufacture and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

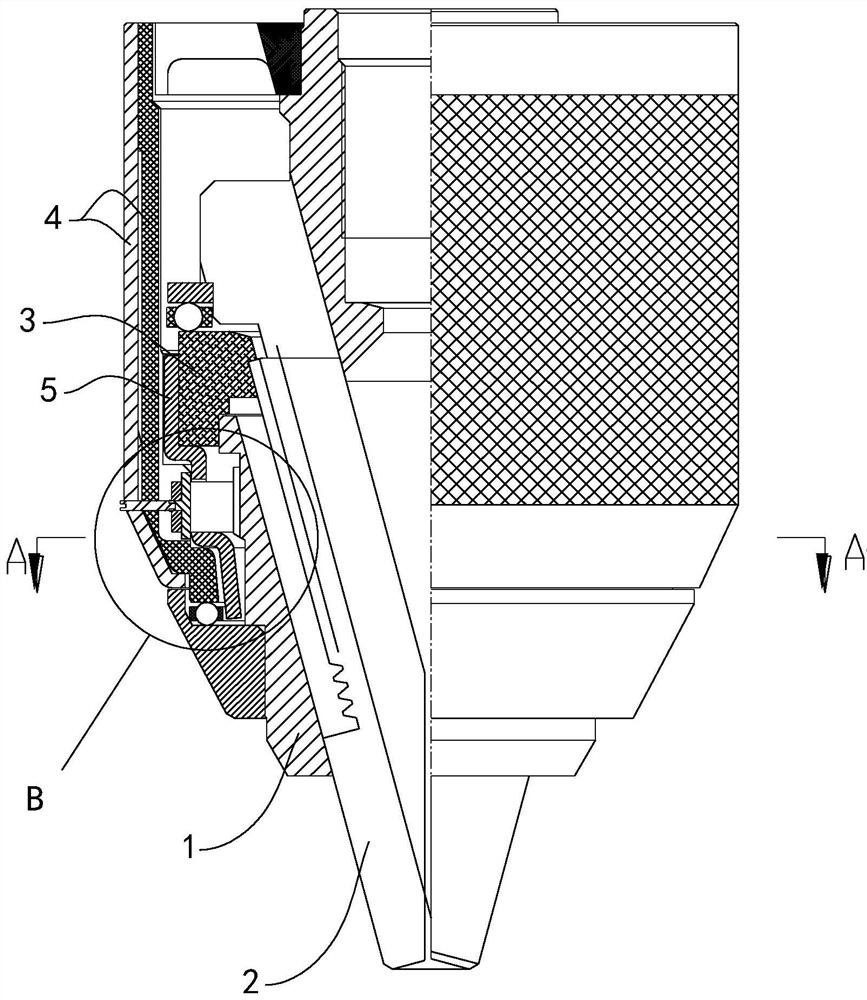

[0029] A self-locking structure of a drill chuck, refer to figure 1 As shown, it includes a drill body 1 , a clamping jaw 2 , a nut 3 , and a rotating sleeve 4 . The drill body 1 is installed vertically, and there are three clamping jaws 2. The clamping jaws 2 penetrate the drill body 1 obliquely and move in the inclined direction to realize opening and closing. , the back of each jaw 2 has a threaded structure. The rotating sleeve 4 and the nut 3 are clamped and fixed. The rotation of the rotating sleeve 4 can drive the nut 3 to rotate, and the nut 3 realizes the oblique movement of the clamping jaw 2 on the drill body 1 through the cooperation of the threads, so as to realize the opening and closing clamping operation. The screwdriver can be assembled in the clamping jaw 2 , and then a motor can be connected to the upper end of the drill body 1 to drive the drill body 1 to rotate.

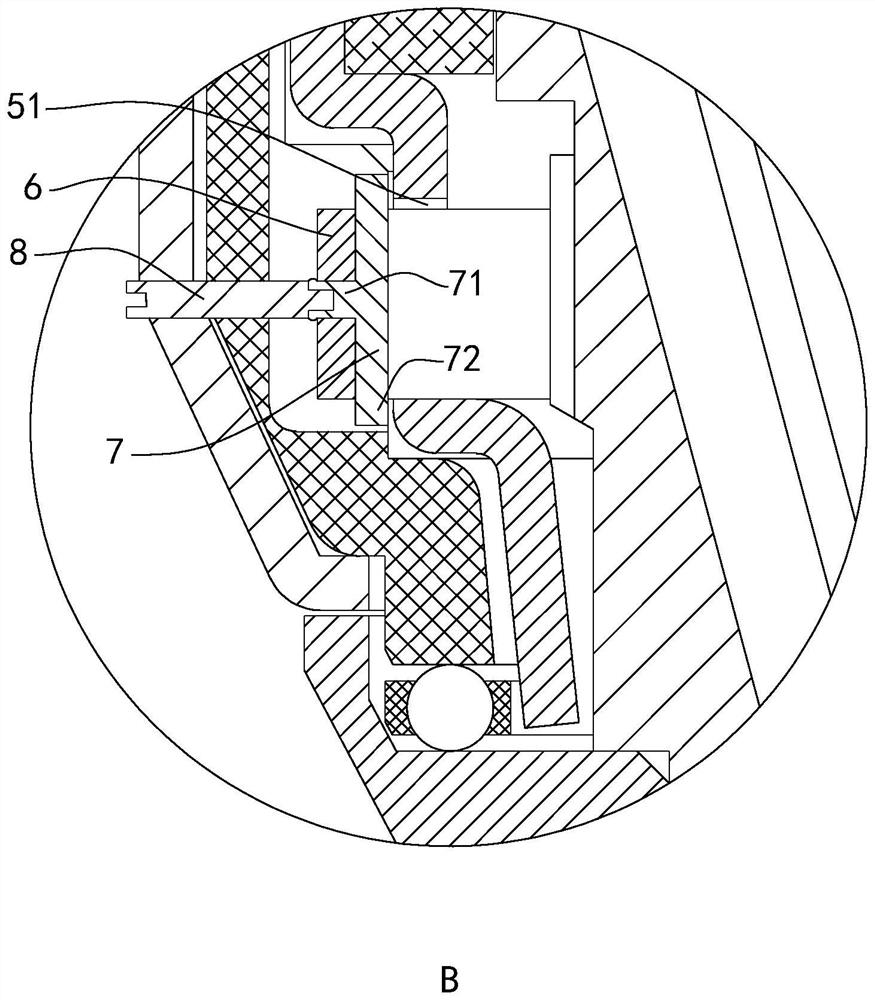

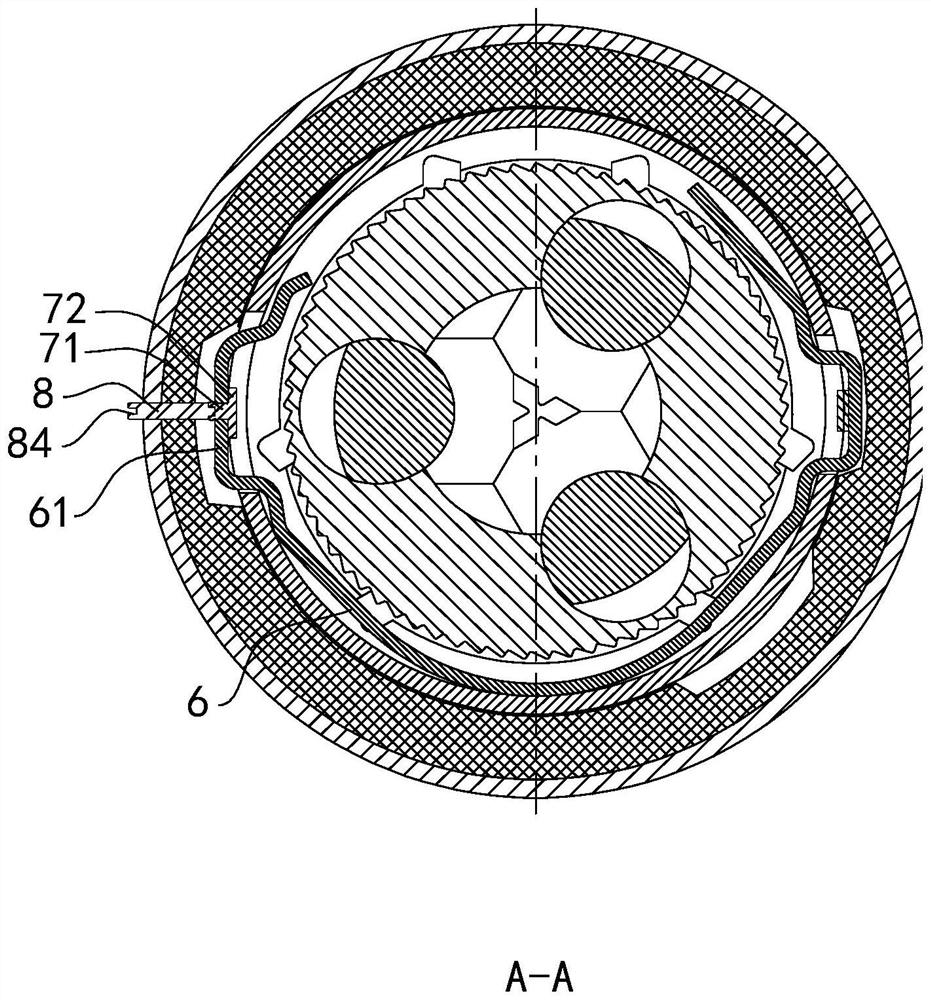

[0030] combine figure 1 , image 3 and Figure 4 It can be seen that a ratchet portion ...

Embodiment 2

[0037] Based on Example 1, refer to Figure 5 and Image 6 As shown, in order to realize the linkage between the connecting rod 8 and the locking piece 7, the connecting rod 8 and the locking piece 7 are provided with an inner hole 85, the inner hole 85 is provided with a rope body 9, and one end of the rope body 9 is fixed on the locking piece 7, the rope body 9 passes through the locking piece 7 and the connecting rod 8 and extends out of the connecting rod 8. The rope body 9 can be pulled, so that the connecting rod 8 and the rotating shaft 71 can be connected more quickly, or the elastic spring plate 6 can be pulled by pulling the rope body 9, so that the elastic spring plate 6 can be kept away from the ratchet portion 11 .

[0038] In order to facilitate the operation of the connecting rod 8 , a tool slot 84 is provided on the outer end of the connecting rod 8 . The tool slot 84 is a "cross" slot or a "one" slot.

[0039]The design of the locking piece 7 has multiple e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com