Transmission support and sliding device

A technology of transmission bracket and sliding device, which is applied in the direction of feeding device, metal processing equipment, metal processing machinery parts, etc. It can solve the problem that the resistance of the screw is large or small, which affects the position accuracy of the slide table and the force of the screw in the screw system. Uncertain size and direction etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

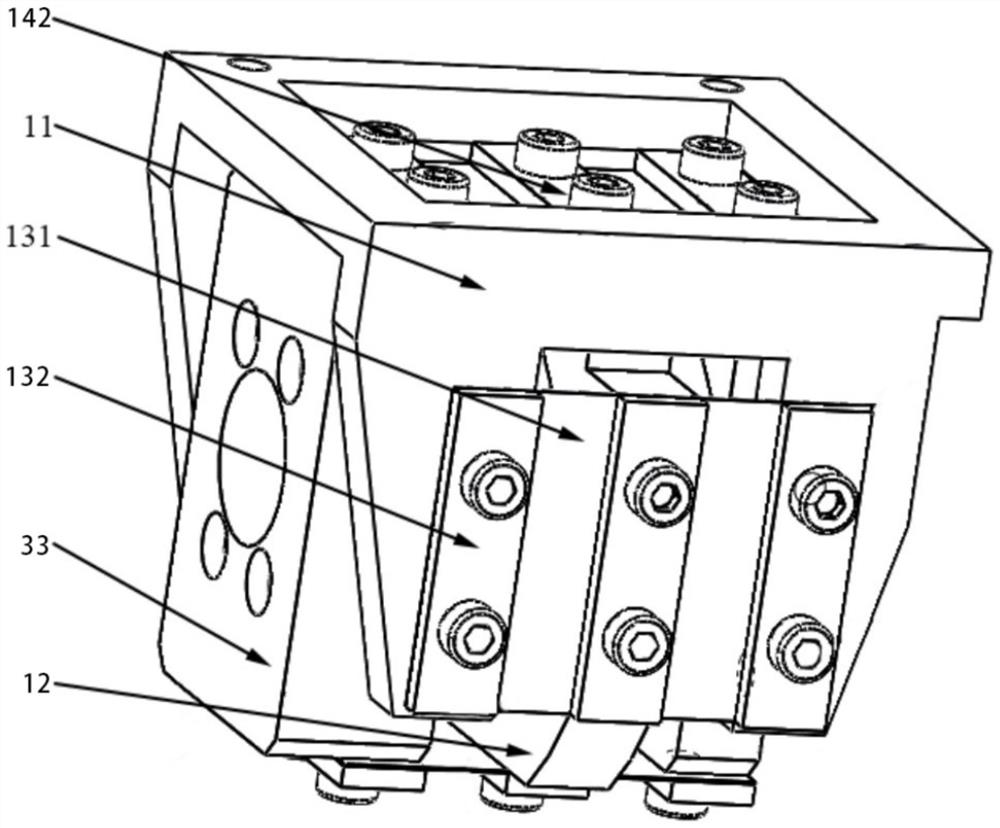

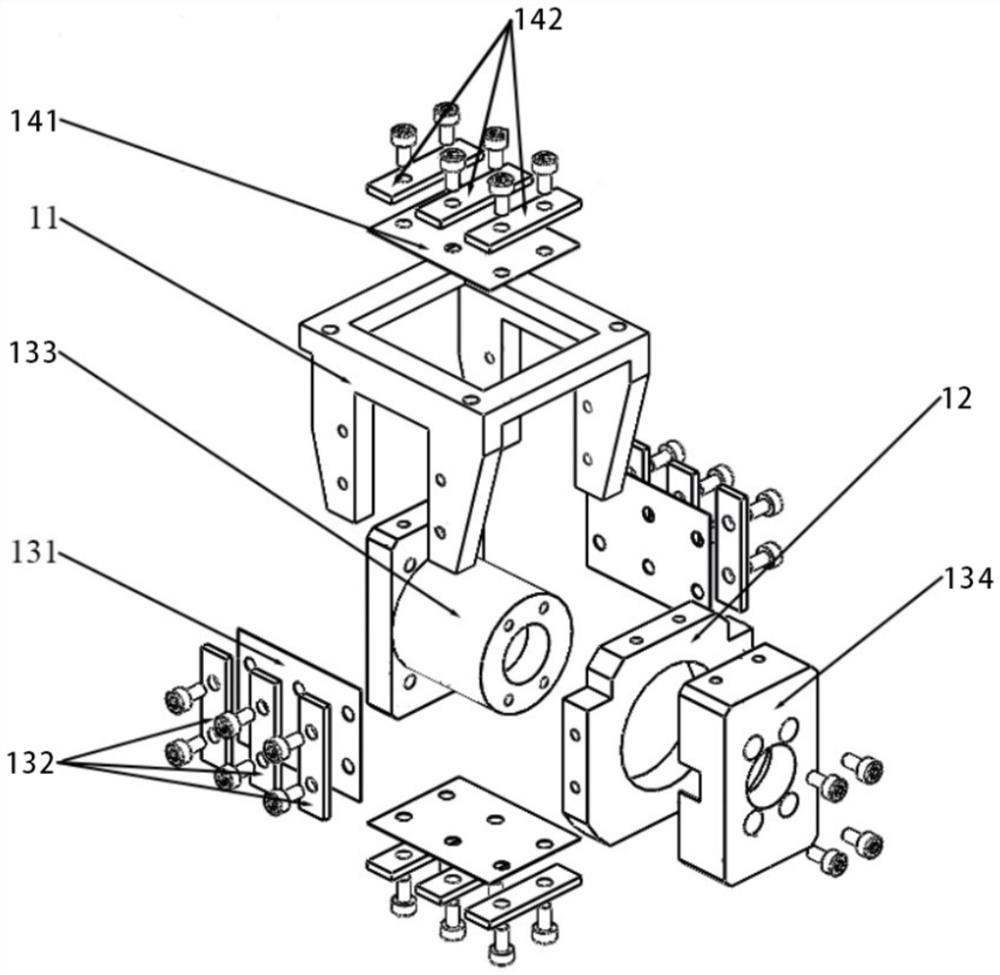

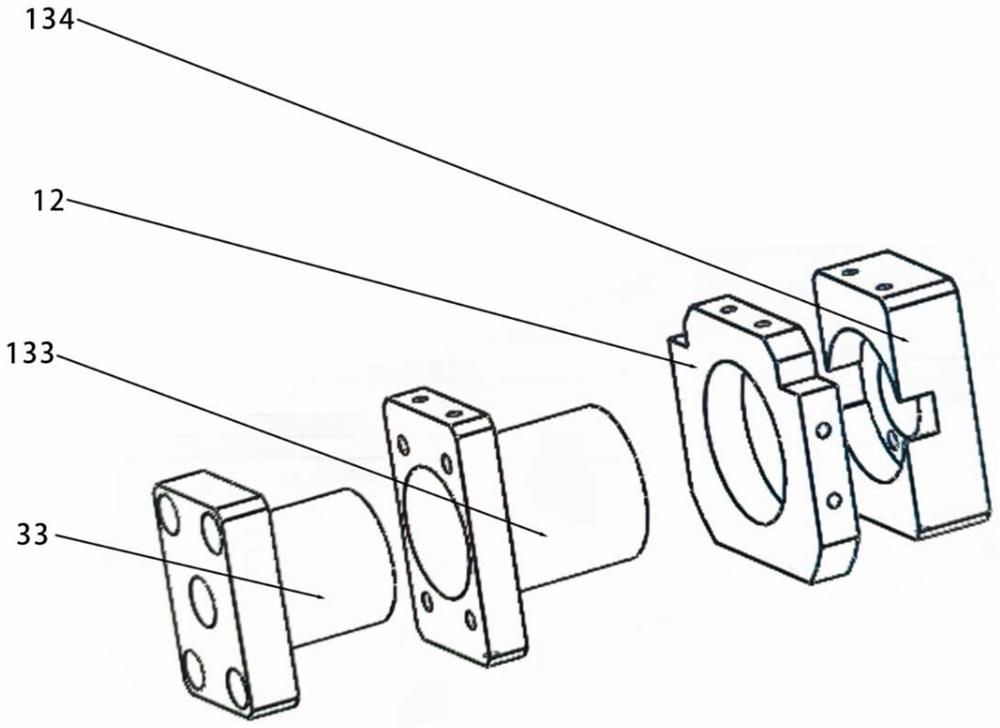

[0043] This embodiment provides a transmission bracket 1, such as Figure 1 to Figure 3 As shown, it includes a bracket body 11, a force transition piece 12, a first elastic structure 13 and a second elastic structure 14. The bracket body 11 is fixedly connected with the sliding assembly, and the force transition piece 12 is installed between the drive assembly and the bracket body 11. During this time, the first elastic structure 13 is installed between the force-bearing transition piece 12 and the drive assembly, the second elastic structure 14 is installed between the bracket body 11 and the force-bearing transition piece 12, and the bracket body 11 is sleeved on the force-bearing transition piece 12 In addition, the force transition piece 12 is a rounded rectangular ring. The force transition piece 12 receives the driving force of the driving component through the first elastic structure 13 and transfers the driving force to the bracket body 11 through the second elastic st...

Embodiment 2

[0048] This embodiment provides a sliding device, such as Figure 4 As shown, it includes a base 2, a driving assembly, a sliding assembly and the transmission bracket 1 in Embodiment 1, the driving assembly is arranged on the base 2, the sliding assembly is fixedly connected with the base 2, and the transmission bracket 1 is arranged on the base 2. between the seat 2 assembly and the sliding assembly.

[0049] like Figure 4 As shown, in the sliding device provided in this embodiment, the sliding component includes a sliding table 41 and a sliding rail 42, and the driving component includes a driving member, a screw rod 31 and a nut member 32. The driving member is a servo motor, and the driving member is fixed to the base by bolts. One end of the seat 2, the driving end of the driving member is connected with the screw rod 31, the two screw rod 31 supports are respectively arranged at both ends of the screw rod 31, the screw rod 31 is slidably connected with the screw rod 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com