Equipment mold for special elevator parts and machining method

A technology for parts and elevators, which is applied to the equipment molds and processing fields of special elevator parts, can solve the problems of time-consuming operation, unfavorable assembly work efficiency, troublesome installation of screws, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

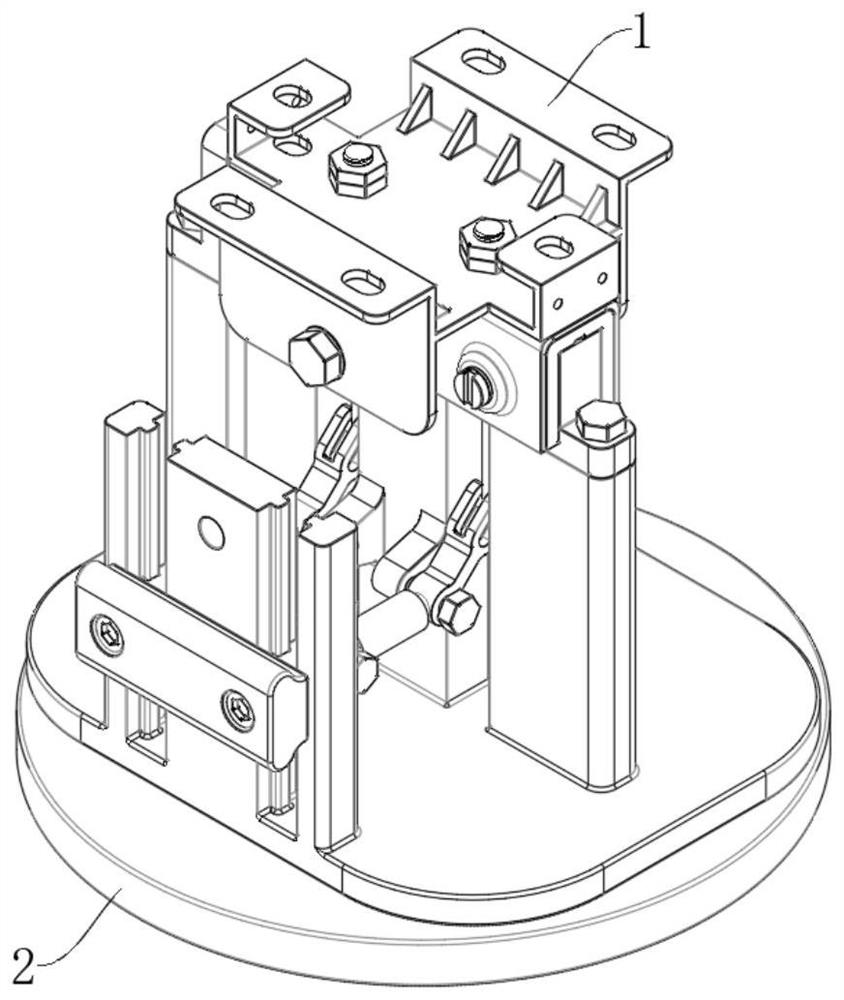

[0094] see figure 1 The present invention provides an equipment mold for special elevator parts, which includes an elevator guide shoe 1 as a special elevator part and a mold 2 used for assembling the elevator guide shoe 1 .

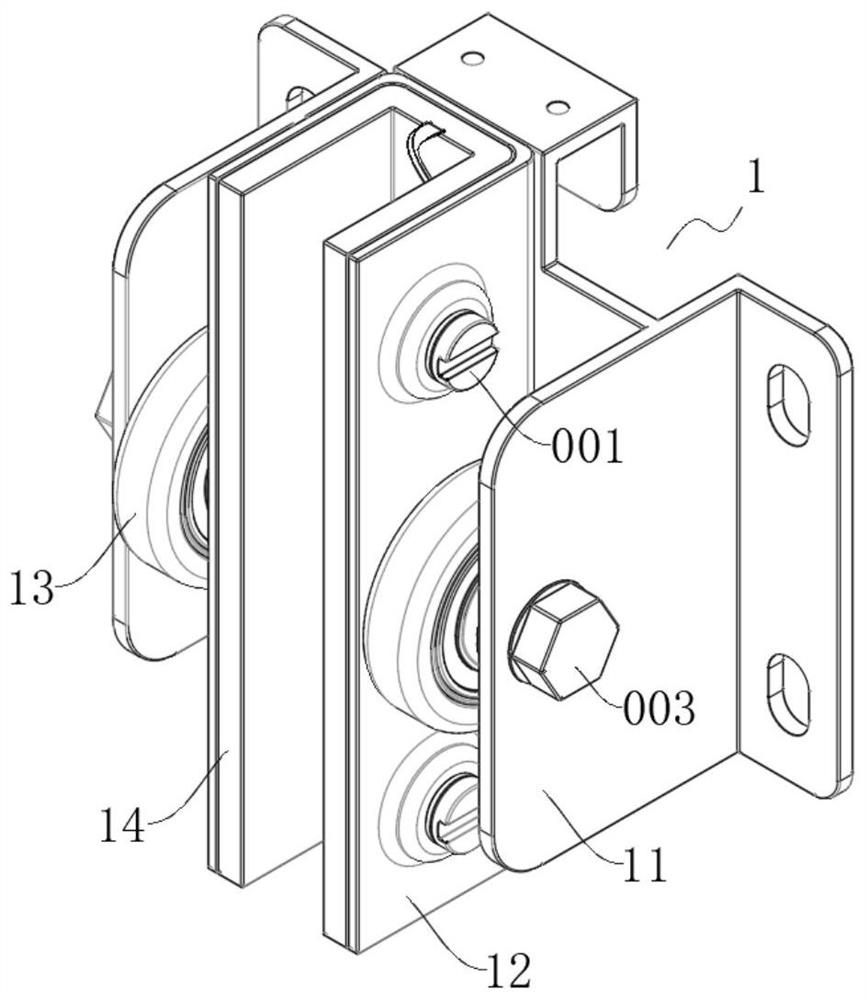

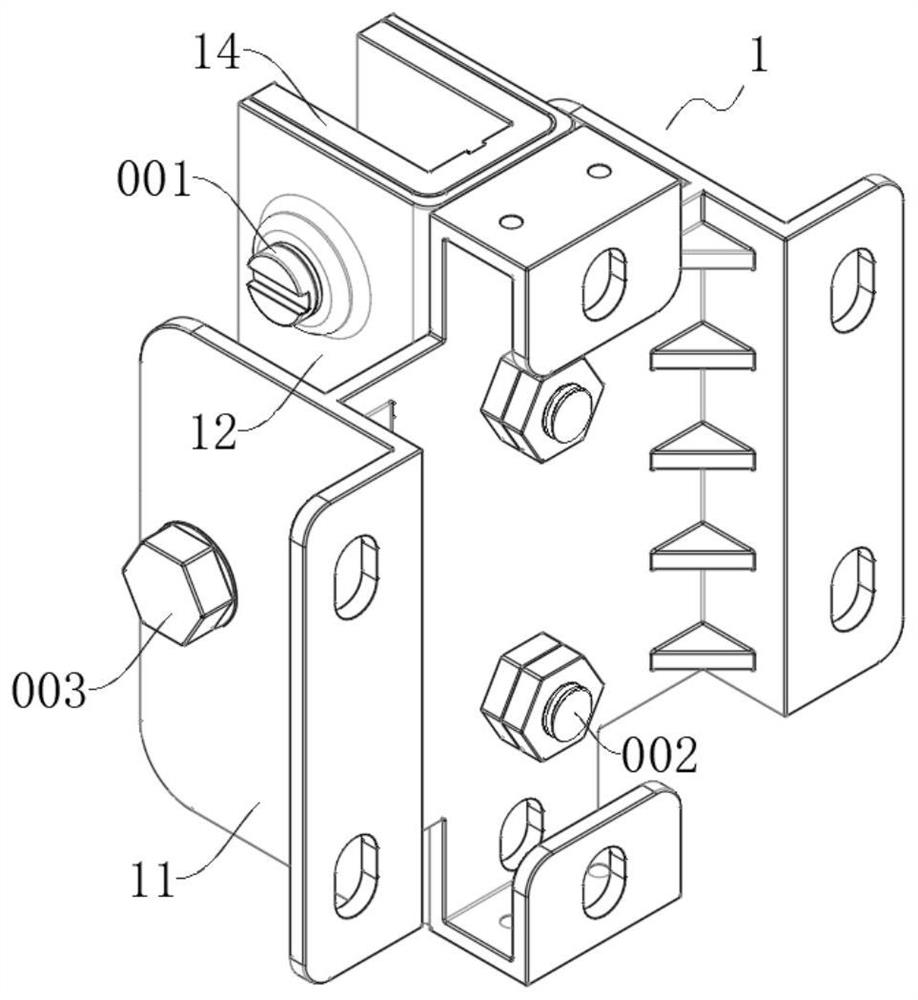

[0095] see figure 2 , image 3 and Figure 27 , The elevator guide shoe 1 provided by the present invention includes a shoe seat 11 , a shoe groove 12 , two guide wheels 13 and a shoe lining 14 . In addition, the elevator guide shoe 1 also includes four screws one 001 , two screws two 002 and two screws three 003 . Wherein, each screw 2002 is equipped with two matching nuts.

[0096] see Figure 4 and Figure 5 , the middle part of the shoe seat 11 provided by the present invention is a metal plate body in the shape of a square plate, and the upper and lower parts of the metal plate body are respectively provided with a hole 01 in the shape of a circular through hole. A 01 is arranged symmetrically up and down.

[0097] The upper and lower parts...

Embodiment 2

[0120] see Figure 28-Figure 32 , The present invention provides a processing method for the elevator guide shoe 1 to be assembled by the equipment mold of the special elevator parts.

[0121] S1. First, push the push rod body 410 upward by hand, so that the push rod 400 is pushed to the front of the upper slot one 205 in the second turntable stand 240 . At this time, the hole eighteen 406 is aligned with the groove one 205, the ball 430 is no longer blocked by the turntable stand 240, and the compressed spring 420 restores its own elasticity and pushes the ball 430 backward, so that the ball The rear ball of 430 is snapped into the inner cavity of the slot one 205 , so that the push rod 400 is limited in front of the slot one 205 .

[0122] In the present invention, when the push rod body 410 is pushed upward, the hinge seat 500 slides upward along the chute 204 under the driving action of the push rod 400, so that the hinge cylinder 600 moves upward, and the hinge cylinder ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap