Collective doffing bobbin conveying system

A conveying system and doffing technology, used in textiles and papermaking, etc., can solve the problems of the driving device not taking good dustproof measures, the storage station tube cannot be removed and replaced separately, and the tray rolls over, so as to avoid falling and reduce maintenance. cost, the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

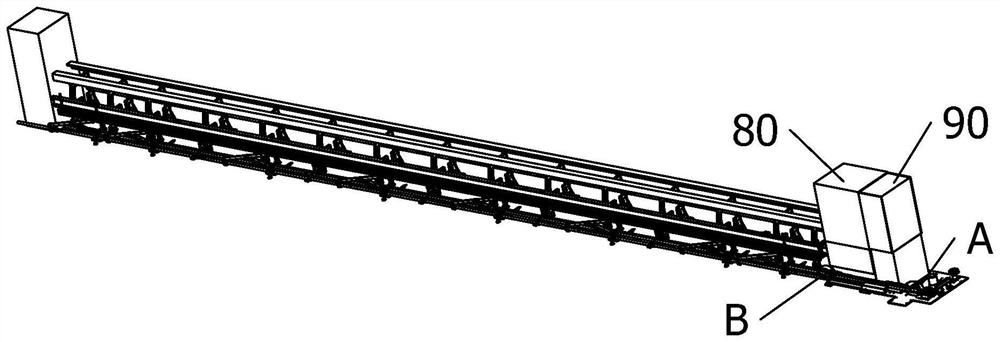

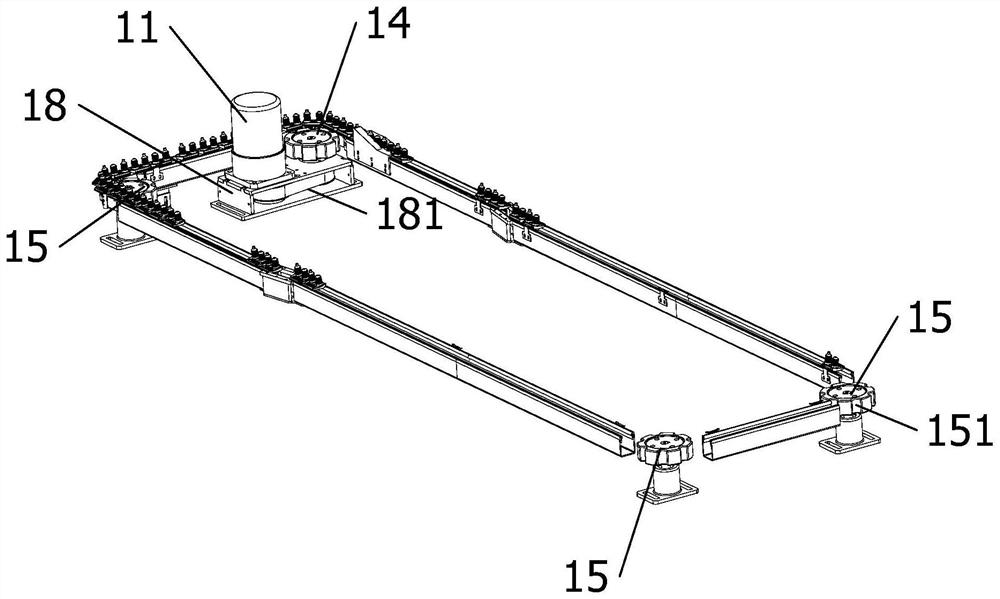

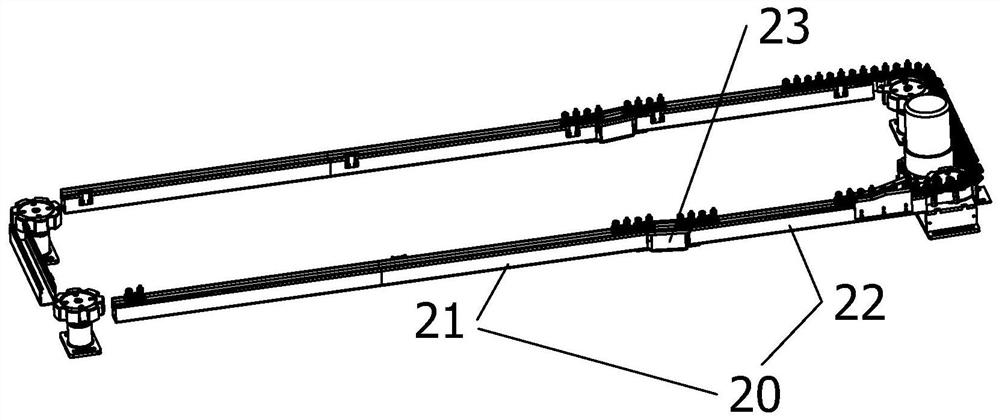

[0036] Attached below Figure 1-14 The technical solutions in the present invention are further described with the examples.

[0037] The present invention provides a collective doffing bobbin conveying system, comprising a track drive device 10, guide rails 20, several tray assemblies 30, a steel belt 40 and a blade 50, the track drive device 10 moves the steel belt 40 in the guide rail 20, and several tray assemblies 30 is fixed with the steel belt 40, so that when the steel belt 40 moves, the tray assembly 30 is moved along with it. When the yarn bobbin on the spindle is full of yarn, the full yarn bobbin is pulled out by the plug-in tube device, and then placed on the tray assembly 30 by the plug-in tube device. All tray assemblies 30 are driven by the steel belt 40 and then move in sequence To the blade 50, because the bottom of the full yarn bobbin on the tray assembly 30 is higher than the upper surface of the blade 50, and the top surface of the tray assembly 30 is lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com