Rotary excavating steel sheet pile under complex stratum and construction technology

A technology of complex strata and steel sheet piles, applied in sheet pile walls, foundation structure engineering, buildings, etc., can solve the problems of increasing construction procedures, construction waste, occupying construction space, etc., to reduce the possibility of water infiltration, reduce The possibility of water seepage, the effect of reducing the influence of the water stop effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

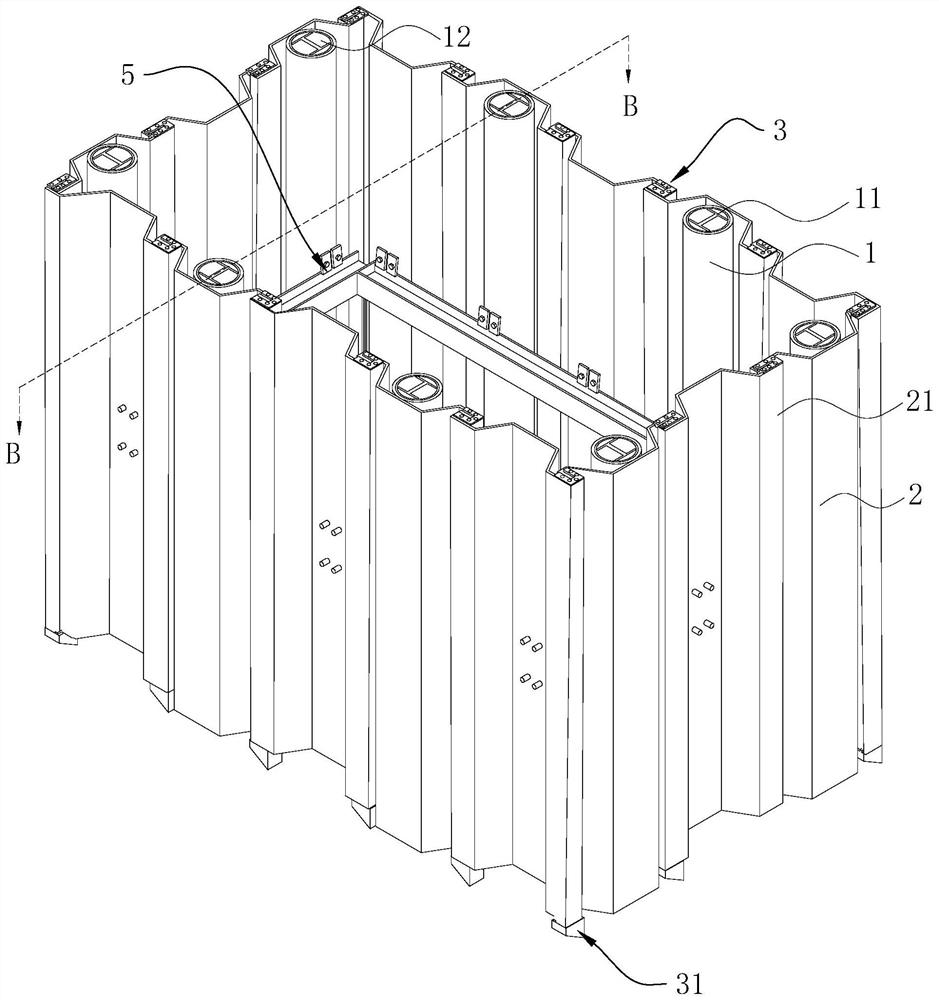

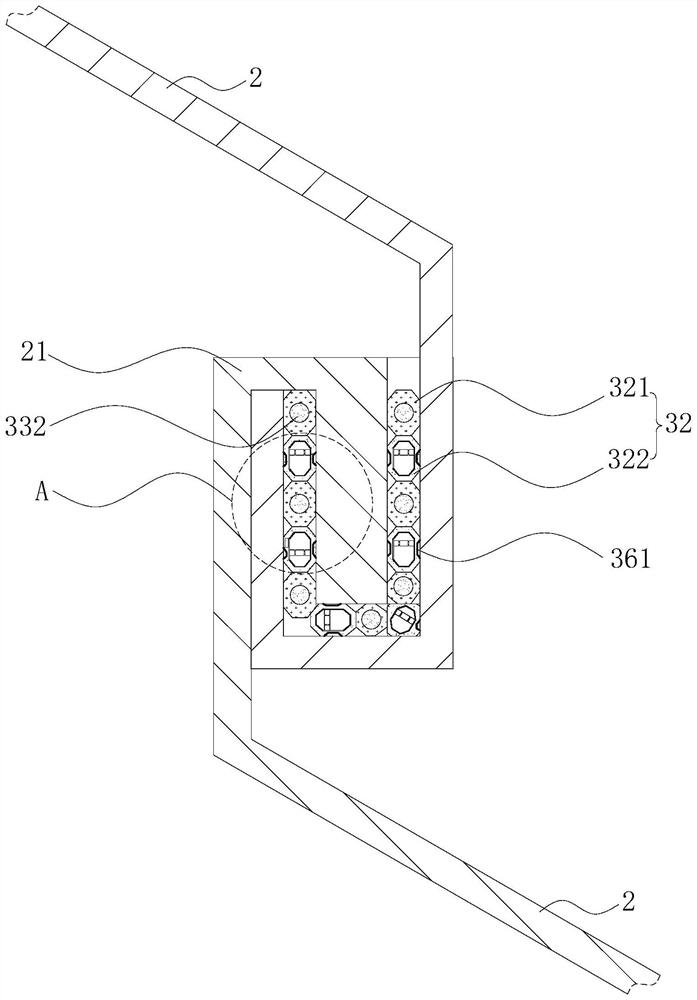

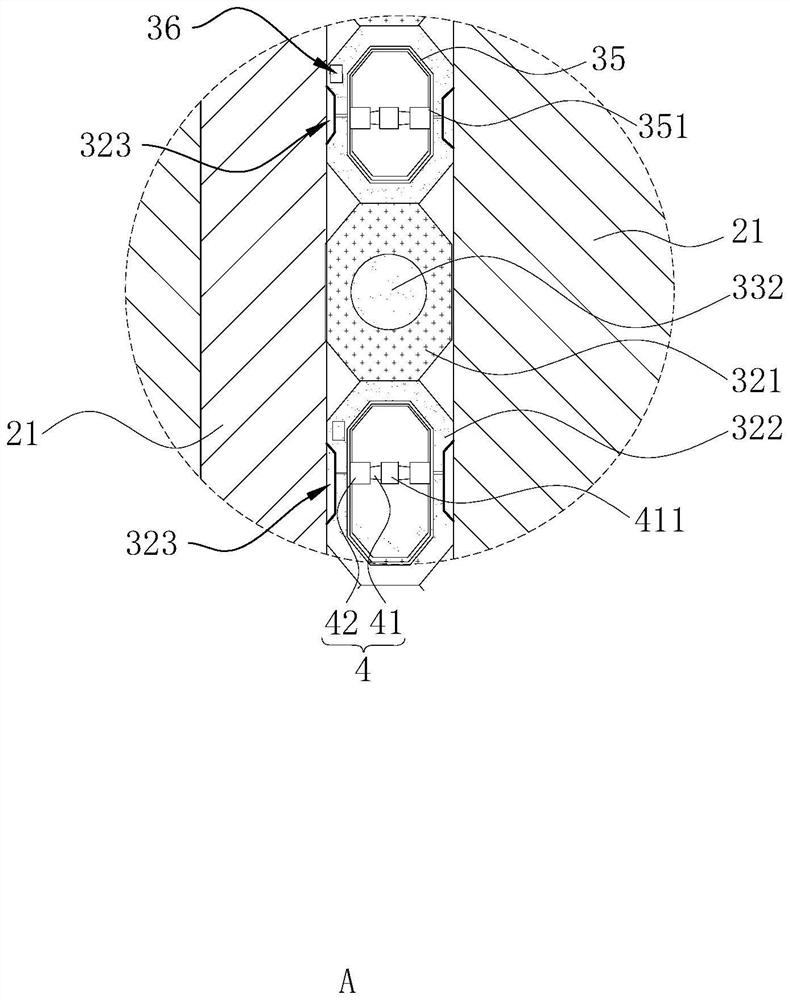

[0046] Attached to the following Figure 1-8 This application will be described in further detail.

[0047] The embodiment of the present application discloses a rotary excavated steel sheet pile under complex stratum. refer to figure 1 , Rotary excavation steel sheet piles under complex strata include a plurality of steel pipe piles 1 and a plurality of steel sheets 2, and the steel pipe piles 1 are in a tubular structure and are inserted into the ground of the construction site. The plurality of steel pipe piles 1 are uniformly distributed in a circular array, and the plurality of steel plates 2 are also uniformly distributed in a circular array. The steel plates 2 are arranged vertically, and the horizontal section of the steel plates 2 is arc or isosceles trapezoid. Among them, the plurality of steel plates 2 are all located outside the plurality of steel pipe piles 1 .

[0048] refer to figure 1 and figure 2 The vertical sides of the steel plate 2 are respectively ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com