Dehumidifying device for prefabricated plywood

A plywood and wet board technology, applied in heating devices, non-progressive dryers, lighting and heating equipment, etc., can solve problems such as uneven heat, moisture is not easy to dry, affect dehumidification effect, etc., to achieve the effect of uniform temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, but not all of the embodiments.

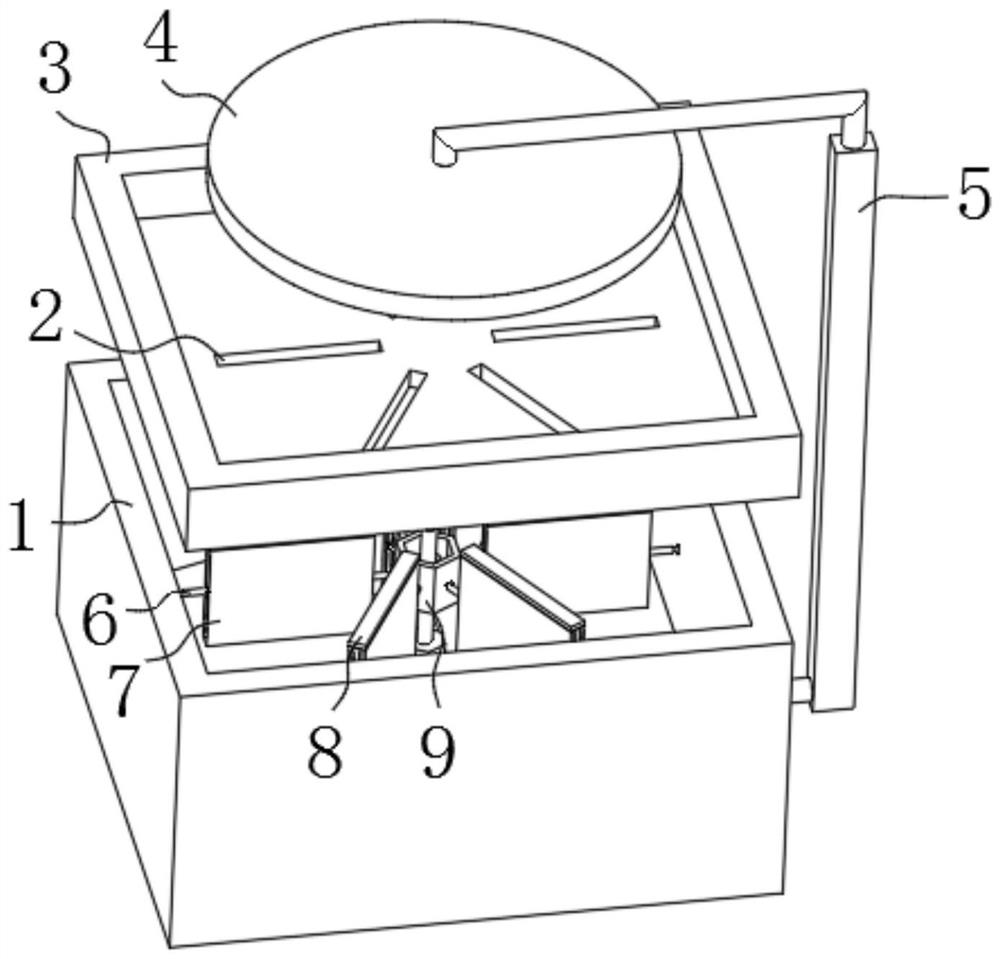

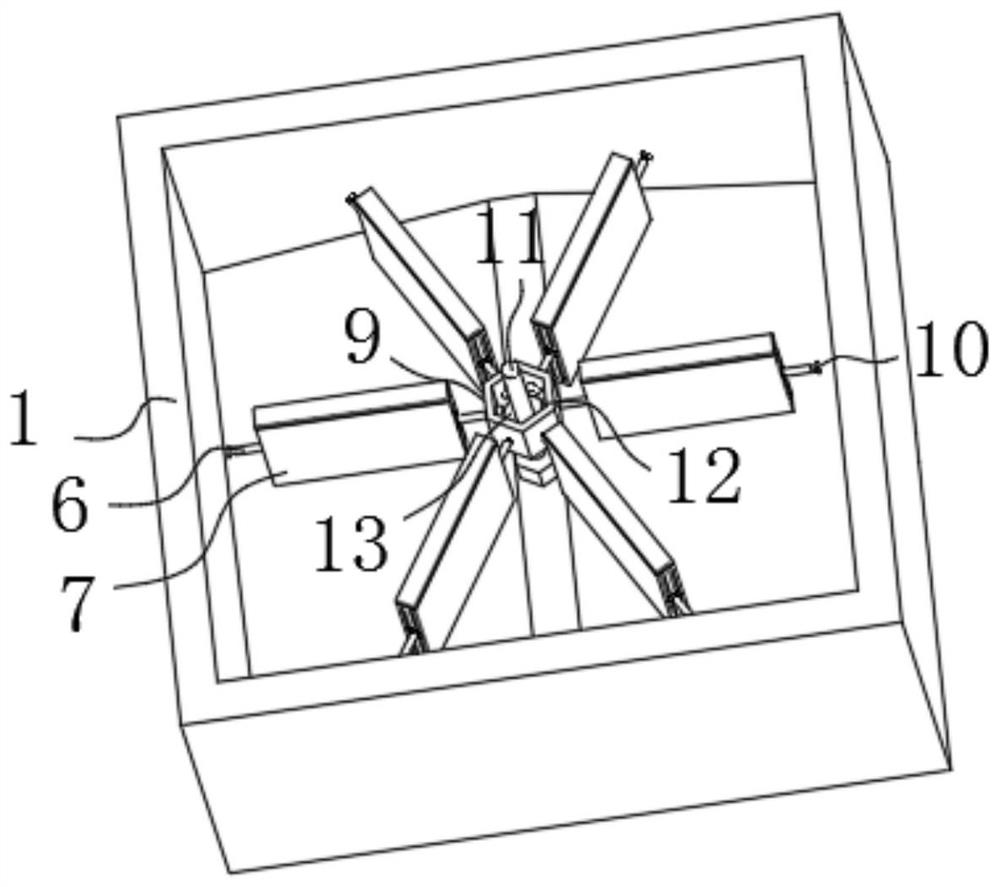

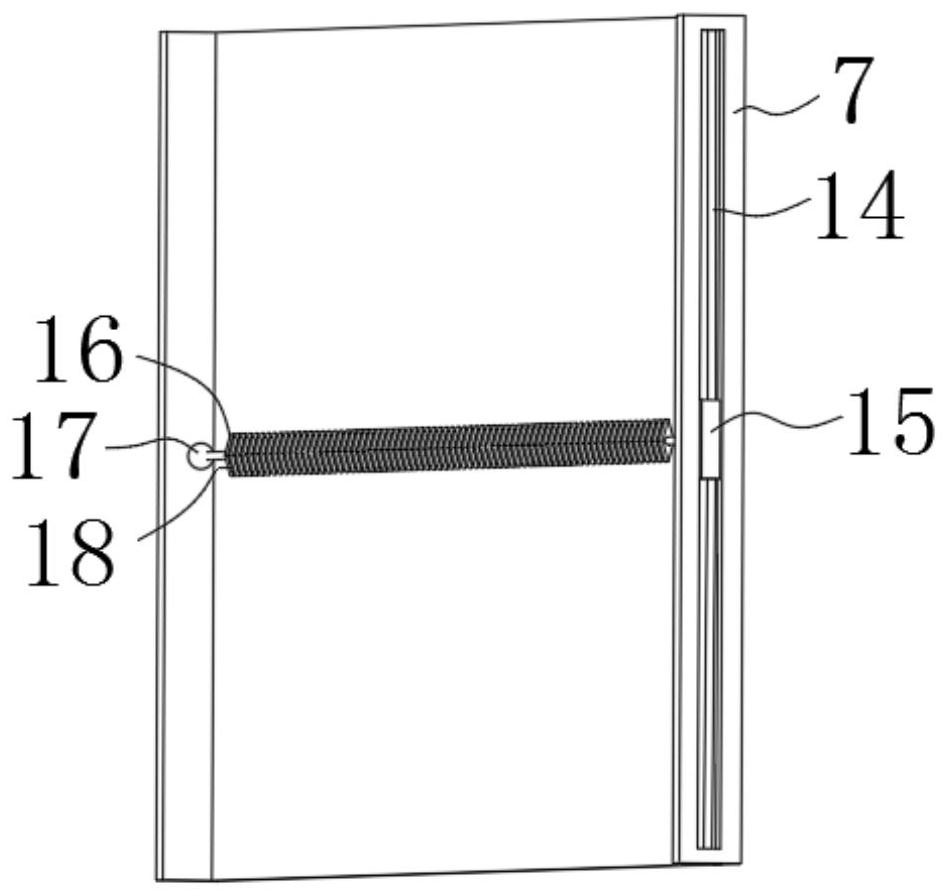

[0021] refer to Figure 1-3 , a prefabricated plywood dehumidification device, including a sand pool 1, characterized in that the sand pool 1 is provided with a variable speed motor, the variable speed motor is installed with a rotating shaft 11, the rotating shaft 11 is installed with a first helical gear 12, the rotating shaft 11 is meshed with The assembly is connected with a plurality of rotating columns 10 , each rotating column 10 is slidably connected with a dehumidification plate 7 , an end cover 8 is installed on the dehumidification plate 7 , the dehumidification plate 7 is filled with hot sand, and the plywood is put into the dehu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com