Vehicle body top cover NVH performance optimization method

An optimization method, the technology of the top cover, applied in the direction of design optimization/simulation, instrumentation, computer material science, etc., can solve problems such as noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

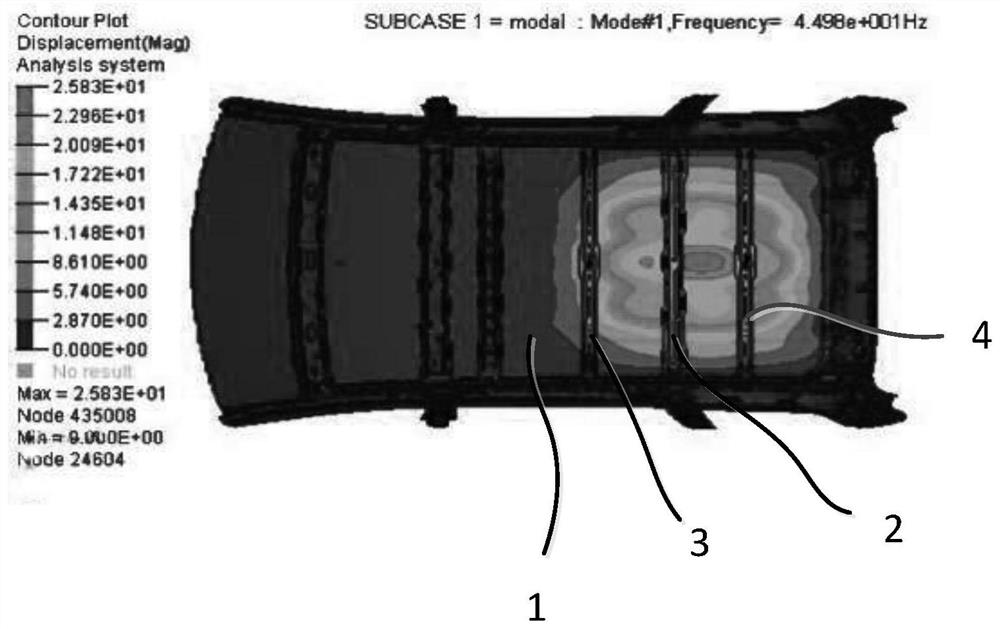

[0036] like image 3 The shown body roof 1, under the modal frequency of 44 Hz, has an obvious area of strain energy mainly concentrated in the middle and rear regions of the body roof 1. The modal strain energy is mainly concentrated on the rear stiffener. At this time, it is difficult to design an accurate damping material layout on the top cover according to the modal strain energy of the stiffener. Therefore, it is necessary to use the dynamic theory of stiffeners to "transfer" the strain energy of the stiffeners to the roof 1 of the vehicle body to complete the design optimization of the damping material.

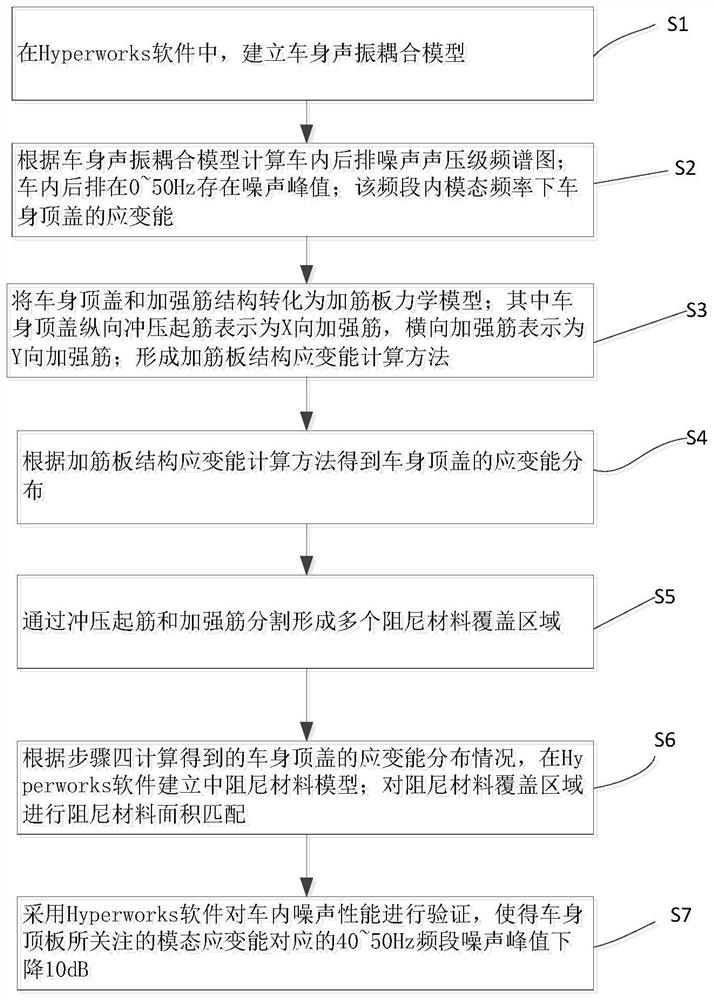

[0037] The specific design optimization steps are basically as follows figure 1 The process involved is completed, which specifically includes step 1 S1: in the Hyperworks software, establish a body sound and vibration coupling model; numerically simulate the vehicle to be designed through the software, so that the simulated body in the software matches the actual ...

Embodiment 2

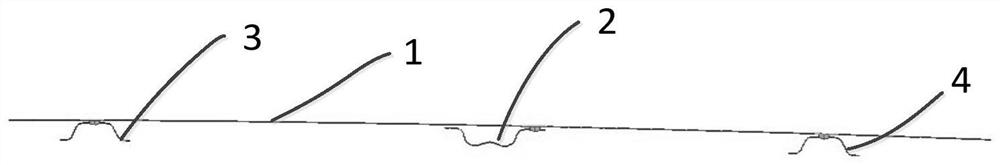

[0057] This embodiment is mainly aimed at figure 2 and Figure 4 The damping material 5 designed for the body top cover 1 is designed according to the steps and calculation methods in Embodiment 1, and the parameters involved in the body top cover 1 are input into the Altair Hyperworks software. generate as image 3 The area of strain energy concentration shown.

[0058] The parameters of the body roof 1 in this embodiment are: the thickness of the body roof 1 is 0.8 mm; the cross section of the main reinforcing rib 2 is 107.21 square millimeters; The cross section of the auxiliary reinforcing rib 4 on one side is 67.41 square millimeters.

[0059] The cross-sectional area A of the main stiffener 2 x 107.21mm 2 ;k x is the shear correction factor, which is 5 / 6; I y is the inertia moment of the stiffener on the y-axis, specifically 2.85e4mm 4 ;J x is the torsional constant, specifically 35.74.

[0060] The cross section of the auxiliary reinforcing rib 3 on the sid...

Embodiment 3

[0070] like Figure 5 The noise decibel diagram of the test at the modal frequency shown, the noise measurement point of the rear seat in the car is in the low frequency band of 40-55Hz. From the test results, it can be seen that the peak value of the noise in the car is attenuated by more than 10dB(A). It is shown that the method can effectively improve the interior noise performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com