Multi-stage electrostatic precipitation equipment based on particle size

An electrostatic dust removal and particle technology, which is applied in the field of industrial dust removal, can solve the problems of poor absorption effect, easy loss of small-quality dust particles, and difficult dust removal voltage, and achieves the effect of improving collection efficiency, reasonable structure and wide application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing:

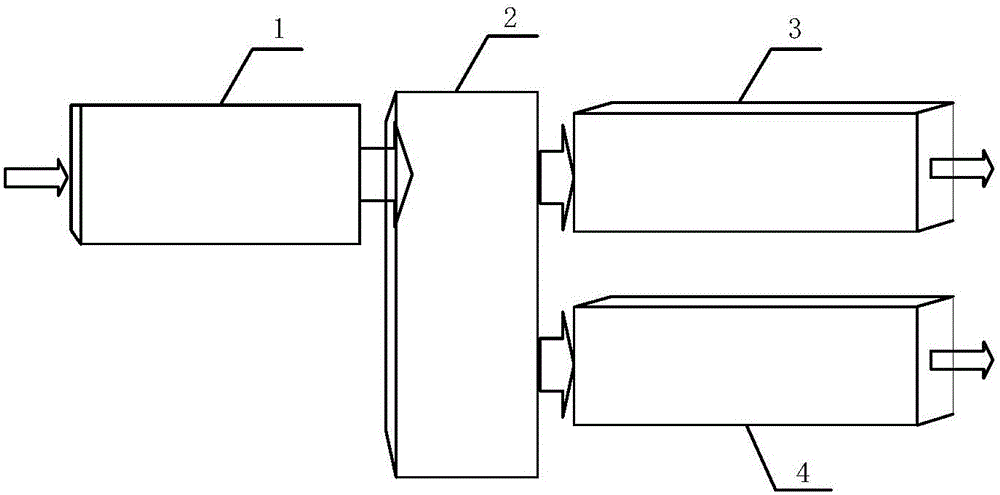

[0021] Such as figure 1 As shown, the dust removal equipment of the present invention is composed of a pre-ionizer 1, a mass separator 2, a large-mass particle dust collector 3 and a small-mass particle dust collector 4 connected in sequence.

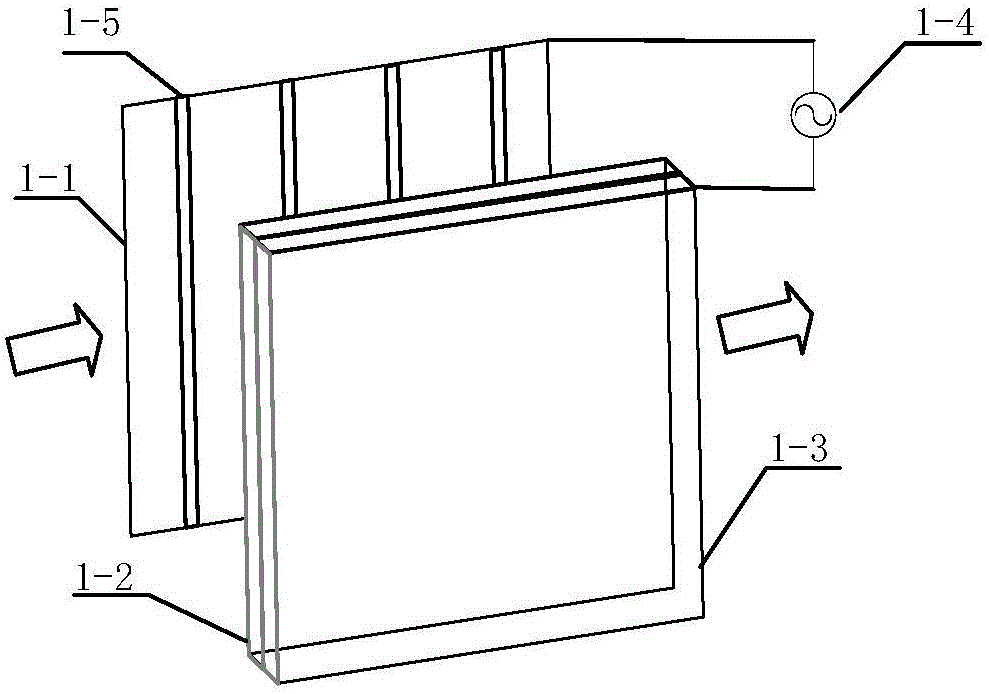

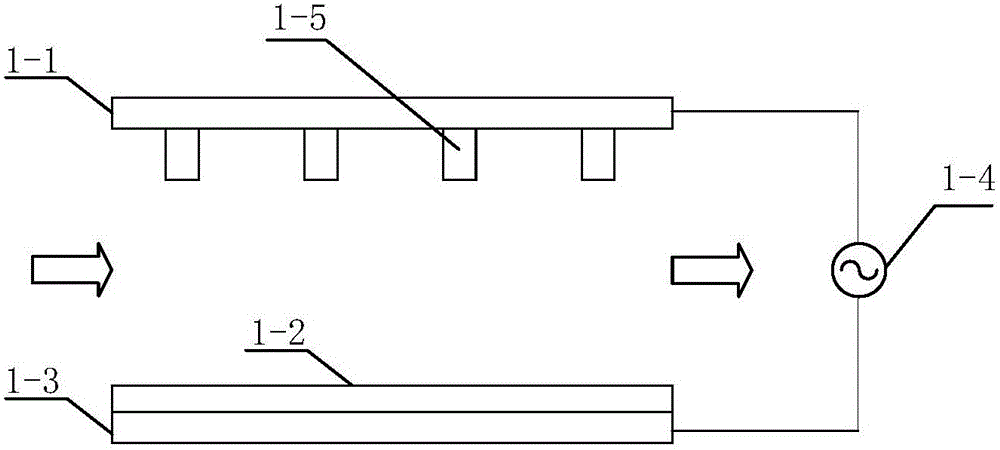

[0022] Such as figure 2 As shown, the pre-ionizer is a cuboid cavity structure, the front end is provided with an air inlet, and the tail end is provided with an air outlet. One of the plates A of the pre-ionizer is a metal with a structure of 1-5 equally spaced ribs. Plate A1-1, the rib-shaped metal plate A can be electrified first; the plate body B facing the metal plate A is made of insulating dielectric plate 1-2 and metal plate B1-3, and the insulating dielectric plate can accumulate charges , to prevent excessive current. The rib of the metal plate A faces the insulating medium plate of the plate body B, and the metal plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com