Automatic hardware assembling machine

An assembly machine and hardware technology, applied in the field of plastics, can solve problems such as bending, reduced service life, and copper sheet damage, and achieve the effects of avoiding narrow space, reducing rebound force, and increasing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

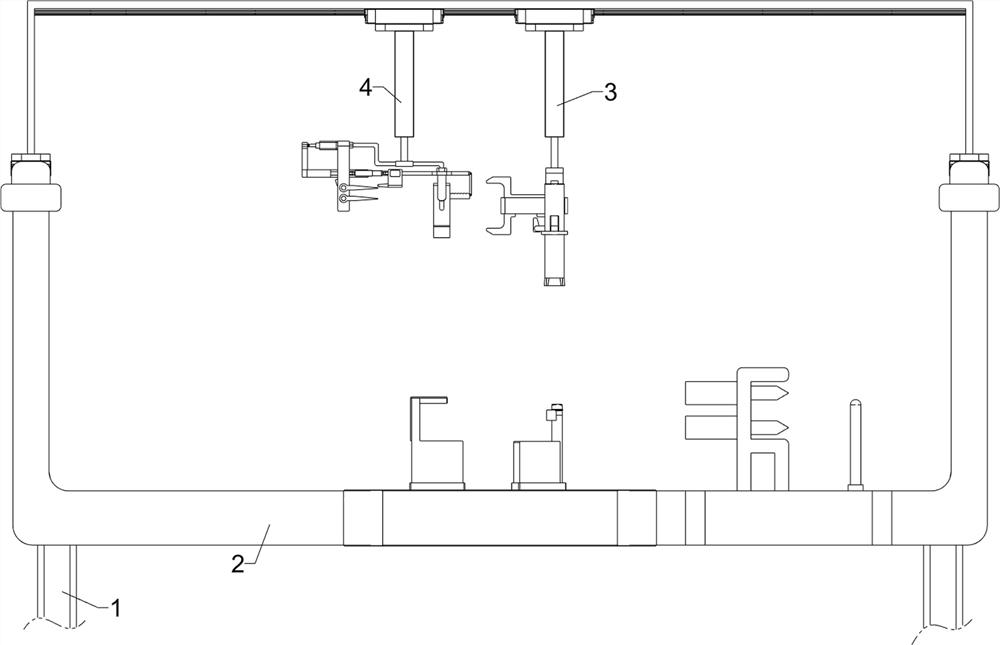

[0040] A hardware automatic assembly machine, such as Figure 1-17 As shown, it includes a base frame 1, a positioning system 2, an installation system 3 and an assembly system 4; the upper part of the base frame 1 is installed with a positioning system 2; the upper part of the positioning system 2 is connected with an installation system 3; the upper part of the positioning system 2 is connected with a Assembly System 4; Mounting System 3 is located in front of Assembly System 4.

[0041] First, the staff installs the automatic hardware assembly machine to the position that needs to be used, and then connects the power supply to control the operation and debugging of the automatic hardware assembly machine. Then the staff fixes the socket housing on the positioning system 2, and then controls the installation system 3. Cooperate with the positioning system 2 to fix the copper sheets of the live wire and the neutral wire, and then control the installation system 3 to snap the ...

Embodiment 2

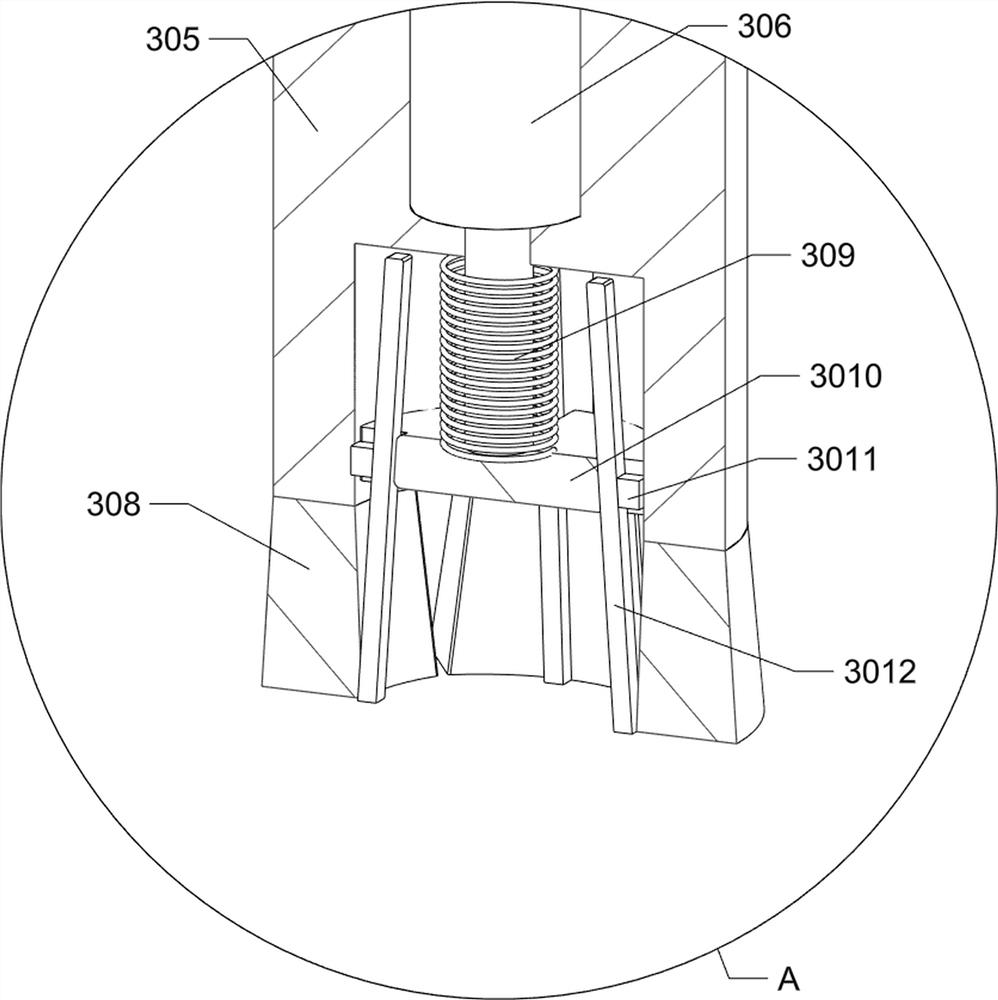

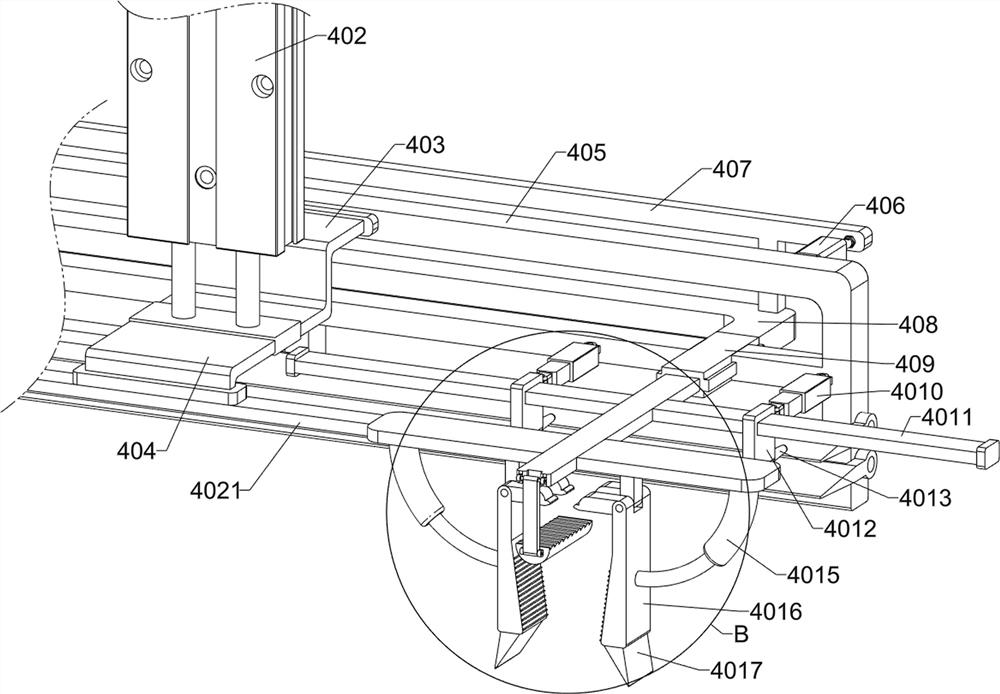

[0043] On the basis of Example 1, as Figure 1-17 As shown, the positioning system 2 includes a first connecting frame 201 , a first electric lifting seat 202 , a first connecting plate 203 , a second electric lifting seat 204 , a second connecting frame 205 , a first electric sliding rail 206 , and a first electric lifting seat 206 . The slider 207, the third connecting frame 208, the second electric sliding rail 209, the limit frame 2010, the first telescopic plate 2011, the first telescopic rod 2012 and the positioning assembly; the upper front part of the base frame 1 is fixedly connected with a first connection The rear part of the first connecting frame 201 is fixedly connected with a first electric lifting seat 202; the rear part of the first electric lifting seat 202 is fixedly connected with two left-right symmetrical first connecting plates 203; two first connecting plates The rear part of the belt 203 is fixedly connected with a second electric lifting seat 204; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com