Fryer capable of turning over automatically

A deep fryer and automatic turning technology, which is applied to the utensils for frying things in oil, kitchen utensils, household utensils, etc., can solve the problems of easy leakage, oil quality and food influence, cumbersome operation, etc., and achieve improved synchronization performance, improve operational convenience, and simplify the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

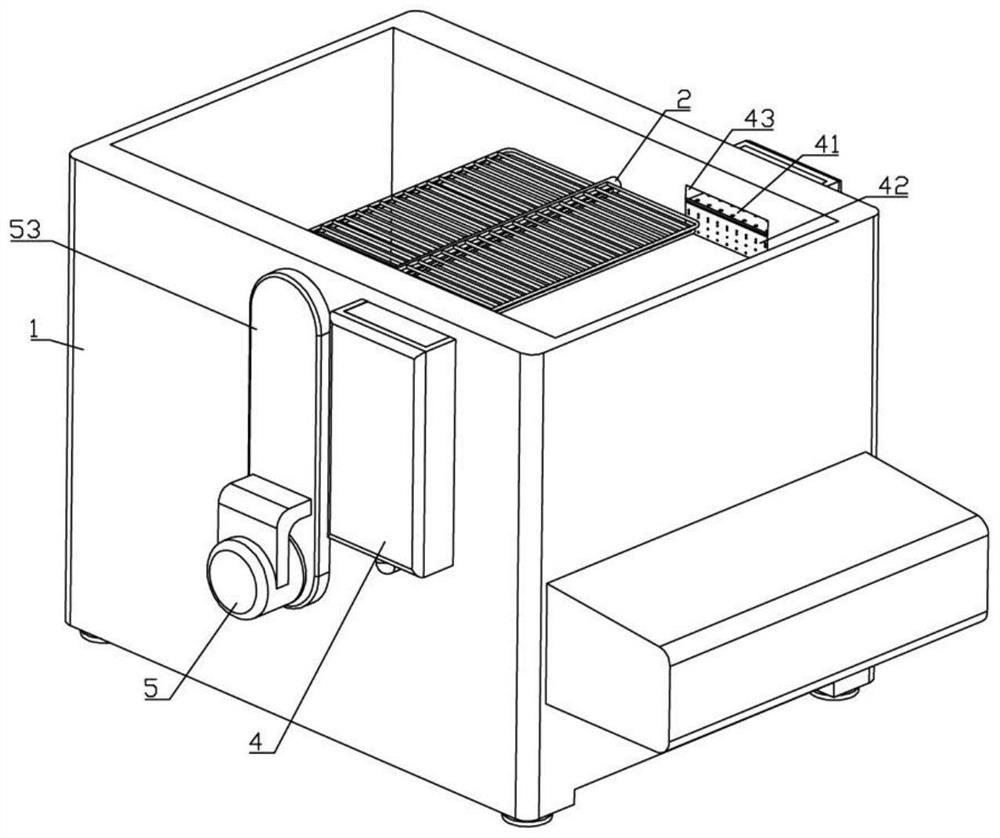

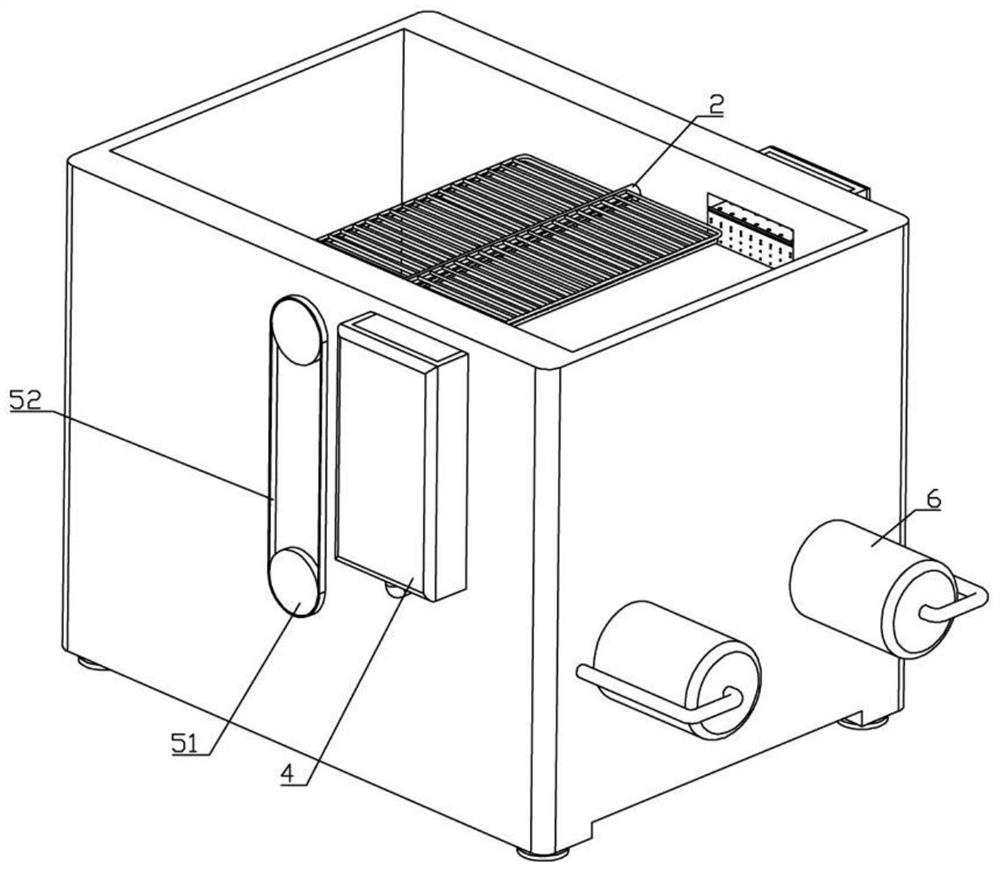

[0030] like Figure 1-6 As shown, a fryer that can be turned over automatically includes a pot body 1 and a control panel. A heater is built in the bottom of the pot body 1. The pot body 1 is provided with a turning mechanism and a slag removing mechanism. are connected with the transmission mechanism;

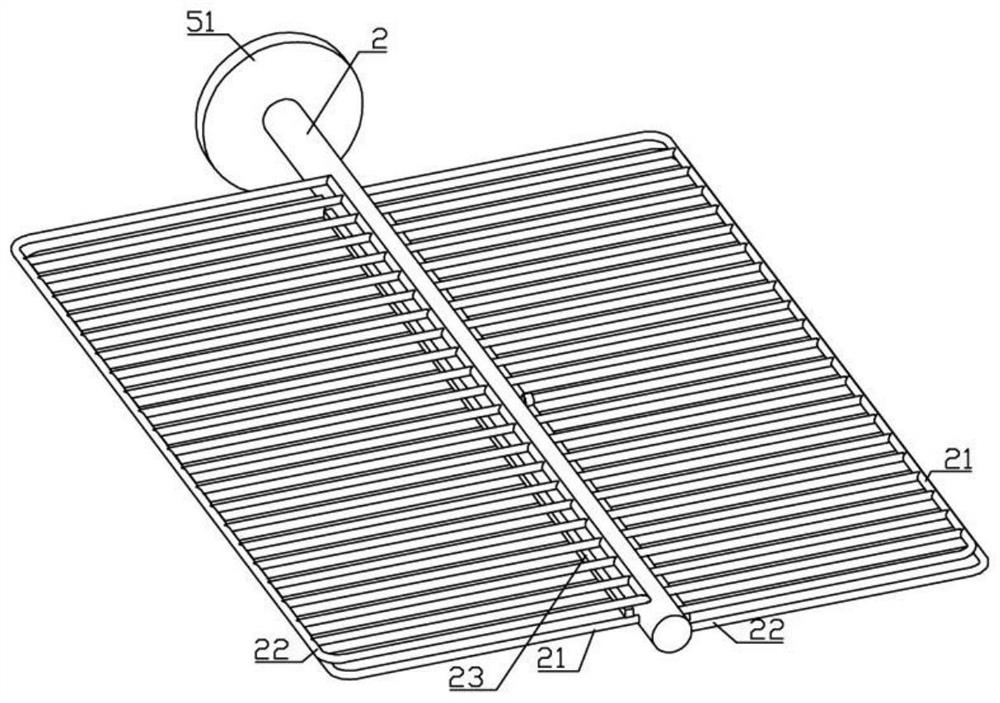

[0031] The turning mechanism includes a rotating shaft 2 and two grippers. The rotating shaft 2 is rotatably arranged on the inner and upper side of the pot body 1 and is connected with the transmission mechanism. The two grippers are arranged on the rotating shaft 2 and are symmetrically distributed around the axis of the rotating shaft 2. The holder includes a fixed grid plate 21 and a movable grid plate 22, and the movable grid plate 22 is connected with the rotating shaft 2 through a damping shaft;

[0032] The slag removal mechanism includes a reciprocating shaft 3, two piston liquid level lifters and two slag collecting boxes. The reciprocating shaft 3 is rotatably arra...

Embodiment 2

[0043] like Figure 7-9 As shown, on the basis of the first embodiment, a pumping mechanism is also provided between the piston liquid level lifter and the slag collecting box. The limit plate 73, the oil storage ring barrel is arranged in the oil storage tank 4, and the oil storage tank 4 is flush with the lower end surface of the oil inlet 43 with a filling plate, and the oil pushing plate 44 is slidingly sealed in the oil storage ring barrel to push the oil The thickness dimension of the plate 44 matches the height dimension of the oil storage ring barrel, the second limit plate 73 is arranged at the lower end of the oil push plate 44, and the inflation air bag 71 is arranged between the second limit plate 73 and the lower inner wall of the oil storage tank 4, and the output The trachea 7 is arranged between the inflation airbag 71 and the piston cylinder 6; between the second limit plate 73 and the oil storage ring barrel, there are several reset devices, the reset devices...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com