Fixing tool method for installing embedded bolt set

A technology for fixing tooling and pre-embedded bolts, applied in the processing of building materials, construction, building structure, etc., can solve the problems of unfavorable construction organization and high comprehensive quality requirements of workers, reduce on-site installation and measurement work, and reduce overall stiffness. High and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

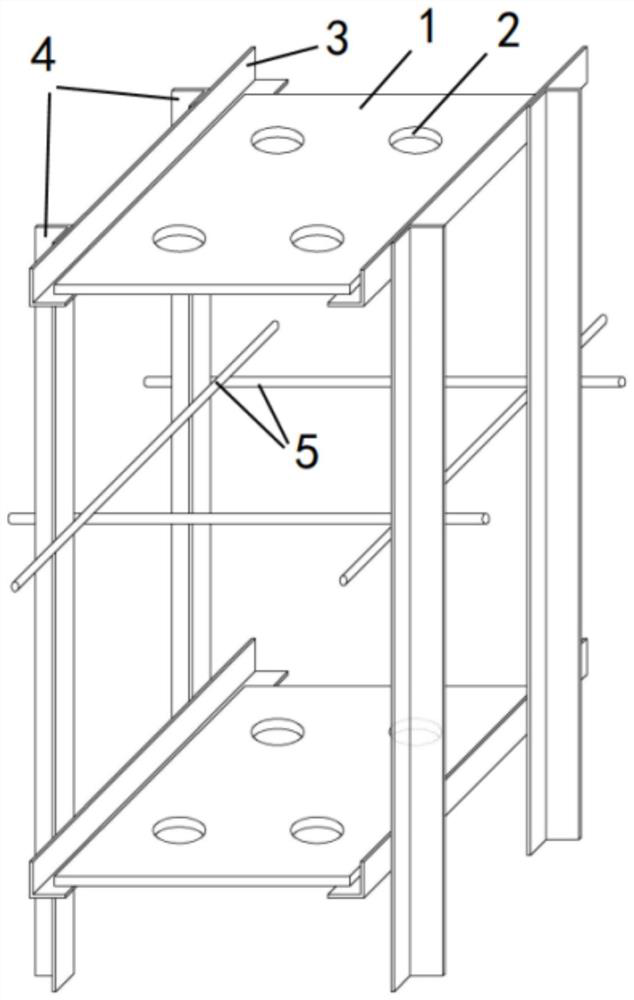

[0025] see figure 1 , the present invention provides a kind of technical scheme:

[0026] A fixing tooling method for installing a pre-embedded bolt group, comprising the following steps:

[0027] The first step is to process the steel plate 1 in the prefabrication workshop, and carry out the opening and finishing processing of the steel plate 1. The deviation of the diameter of the bolt opening 2 and the diameter of the bolt is 0.5~1.5mm, and the deviation of the opening position is -0.5~+0.5mm;

[0028] The second step is to pre-embed and fix the first angle steel 3, the second angle steel 4 and the reinforcing steel bar 5. During the pre-embedding process in the second step, ensure that the upper and lower groups of the first angle steel 3 are on the same horizontal plane, and the vertical wings of the first angle steel 3 are in the same horizontal plane. The distance between the edges is greater than the width of the steel plate 1;

[0029] In the third step, place the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com