Combustion optimization control method based on dynamic operation data analysis

A technology for data analysis and combustion optimization, applied in control systems, complex mathematical operations, lighting and heating equipment, etc., can solve problems such as large deviations in economic indicators of units, improve boiler efficiency, improve stability, steady-state components and fluctuations Component-accurate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention is further outlined below in conjunction with the accompanying drawings.

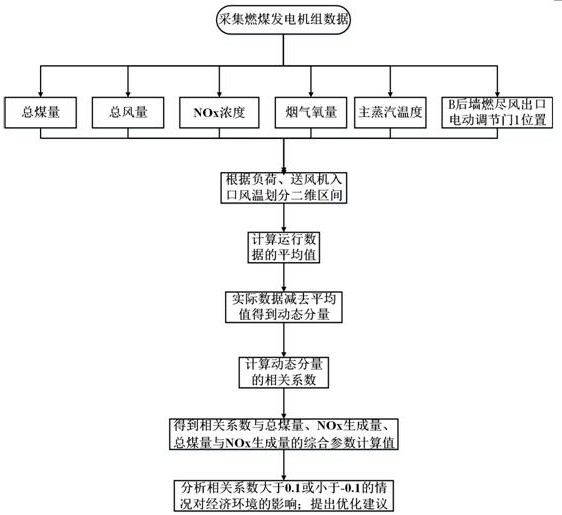

[0035] A combustion optimization control method based on dynamic operation data analysis,

[0036] Step 1: Obtain the relevant historical operation data stored in the DCS of the unit in the past year;

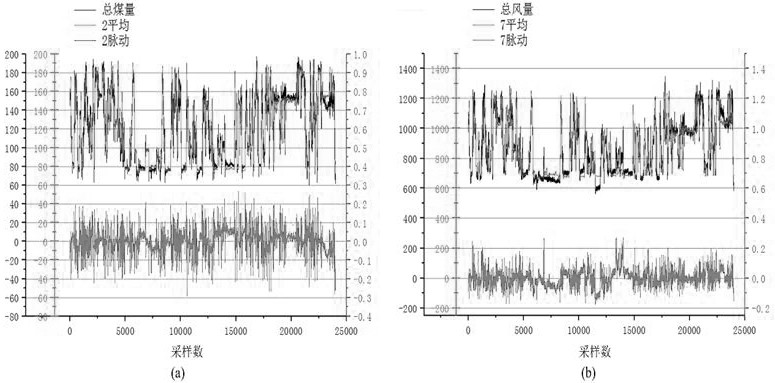

[0037] Select the historical data stored by the DCS of the unit in the past year, and divide the entire load and temperature interval of the unit into 20-30 intervals with a cycle of 1-3min. The load in the load section does not change much, and it can be considered that the load is basically unchanged;

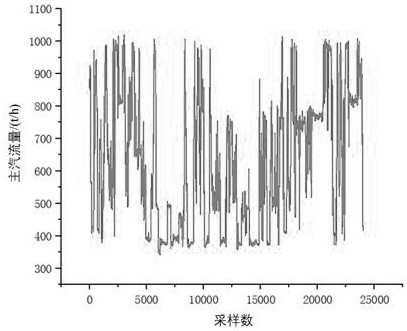

[0038] Step 2: Let all the running data sets be: A(m,k), where m is the sampling number, m=1, 2, 3...M, M is the total number of data samples; k represents the running parameter, k=1,2,3...K; data packets with different loads and temperature ranges are grouped into different data subsets, and the operating data is expressed as: X(i,j,k,l)i represents division The number o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com