Patents

Literature

51results about How to "Reduce the number of alarms" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Network attack detection method

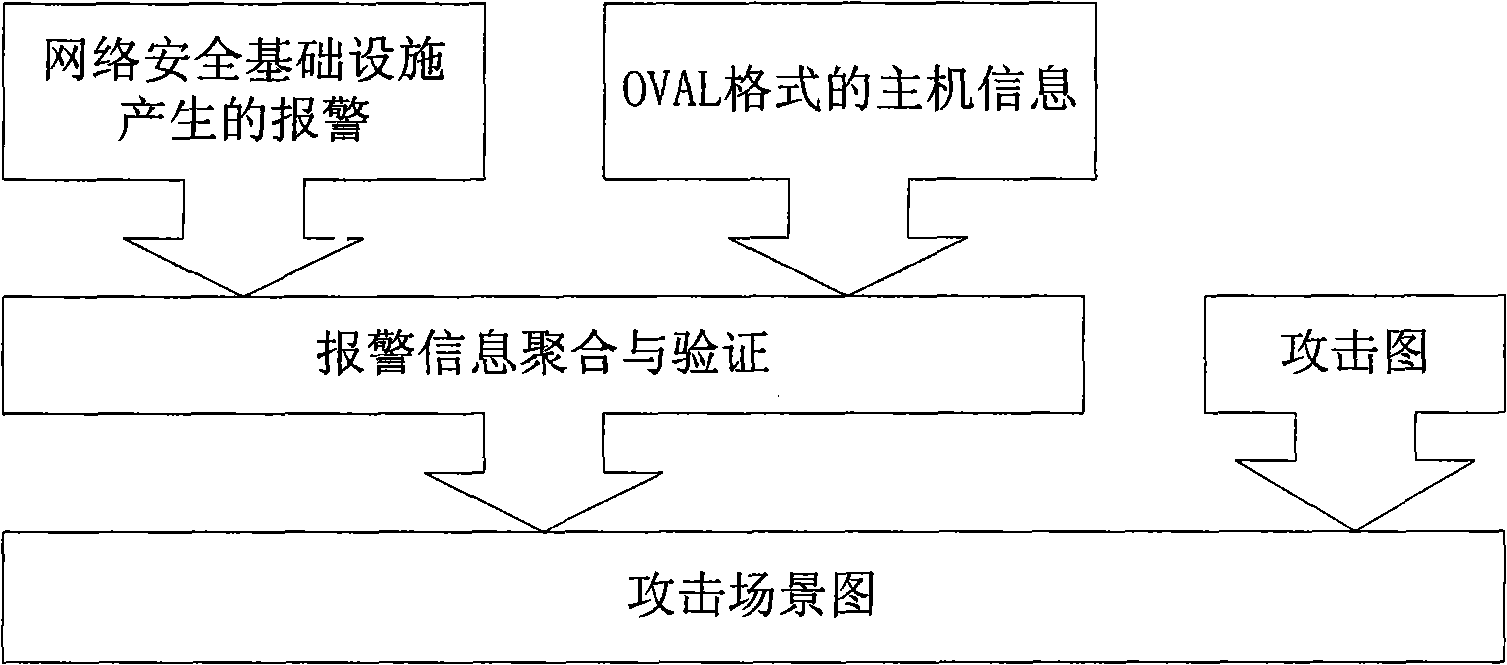

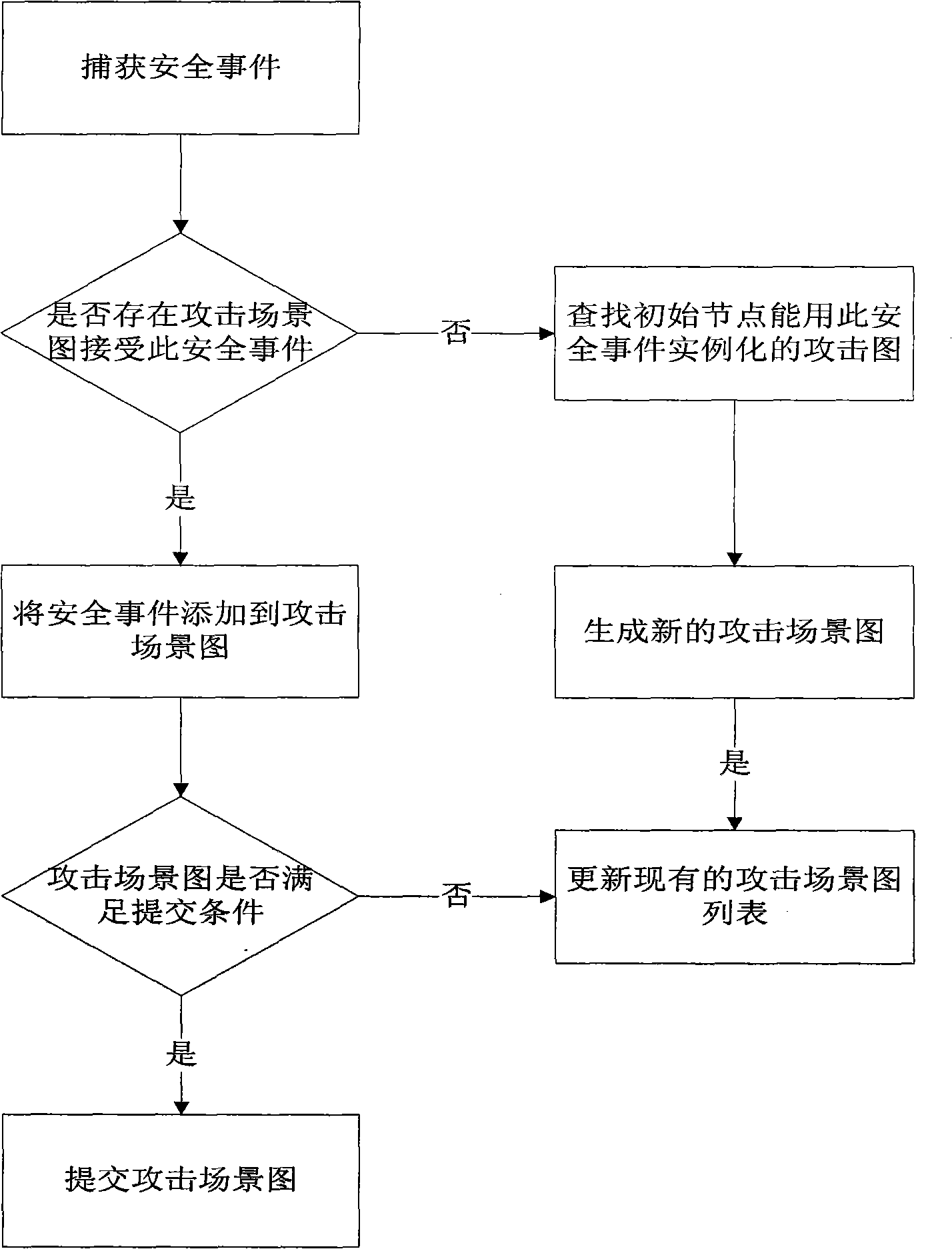

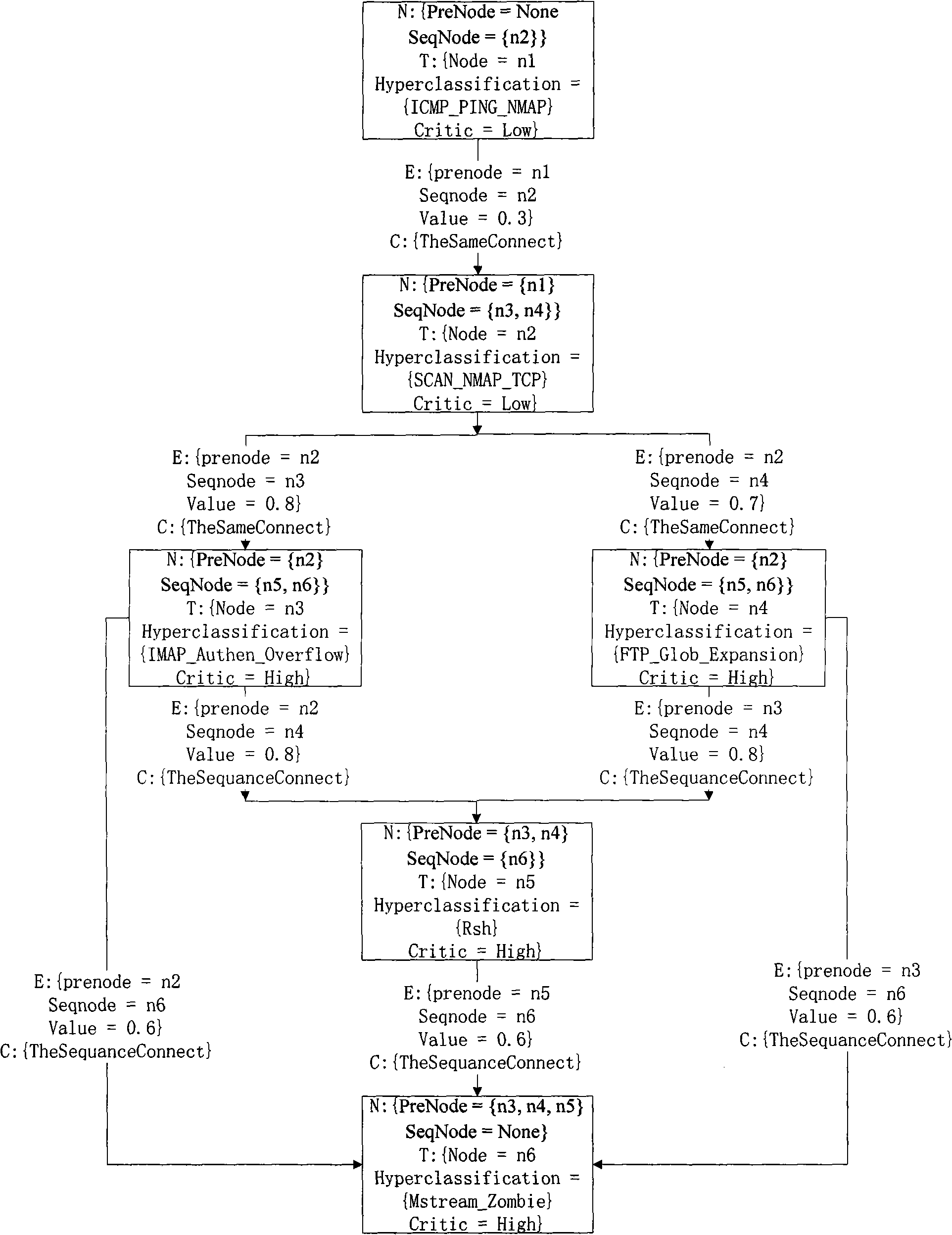

The invention discloses a network attack detection method, which belongs to the technical field of the network safety, and comprises the following steps: 1) alarm which is obtained from a network safety infrastructure is converted to an alarm in a uniform form; 2) the status information of a host computer which is associated to the alarm action is obtained, the alarm association action is judged whether to take effect according to the status information, and when one alarm association action is invalid, the alarm is abandoned, otherwise the alarm is marked as valid; and when the status information of the host computer which is associated to the alarm action cannot be obtained, the alarm is marked as undetermined; 3) valid alarm and undetermined alarm are aggregated to generate a safety event; 4) the attack graph is instantiated by the generated safety event to obtain an attack scene graph; 5) and the attach scene graph which satisfies the conditions is outputted, and the attack type is determined. The method effectively reduces the expenditure of the attack graph algorithm, and is free from reducing the timeliness of the discovering process while improving the network attack accuracy.

Owner:INST OF SOFTWARE - CHINESE ACAD OF SCI

Bonded bleed-out judging and alarming method

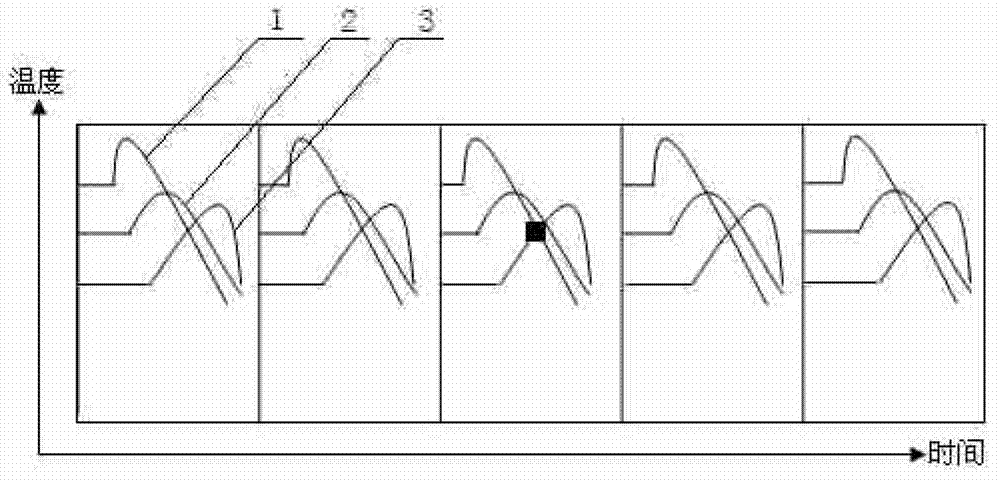

The invention provides a bonded bleed-out judging and alarming method. When a temperature monitoring screen of a crystallizer displays that an appeared temperature curve takes one thermocouple as a center or a starting point, the temperature curves of the thermocouples on both sides (one side) are similar to those of an alarm thermocouple, but the response time of the temperature curves of the thermocouples is changed in the manner of successive lagging, and when the temperature monitoring screen of the crystallizer displays that all the rows of the temperature curves are intersected, i.e. the bonded bleed-out is judged, and an alarm is given. At the same time, a continuous casting machine sharply slows down and enters a creep state, carries out a shell removing treatment on an internal blank shell of the crystallizer, and then accelerates the pulling rate slowly to a setting pulling rate. According to the invention, the alarm accuracy of the bonded bleed-out is improved greatly, and the alarm times and the rapid speed-down times of a casting machine are reduced, so that the problems of deepened vibration marks on the surface of a casting blank and reduction in the constant speed rate of a continuous casting machine due to the rapid speed-down of the casting machine are solved. Therefore, the productivity of the continuous casting machine and the internal quality of the casting blank are improved, the blanks with lapping defects and the quantity of waste products are reduced, and the yield of continuous blank casting is improved.

Owner:ANGANG STEEL CO LTD

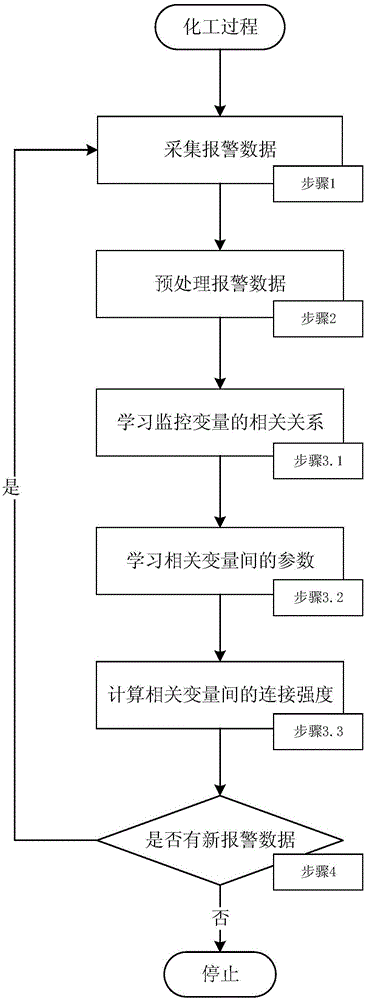

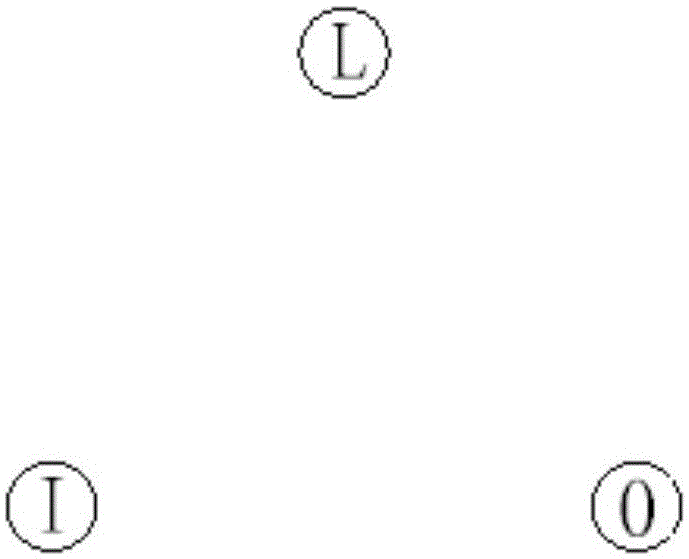

Alarm system optimization method based on bayesian network

The invention discloses an alarm system optimization method based on a bayesian network. The optimization method comprises the following steps: firstly, alarm data is collected, and the alarm data comprises alarm variables and alarm kinds; secondly, pretreatment of the alarm data is carried out, a data set used for bayesian network learning is generated according to states of the alarm variables; thirdly, correlation relations among the alarm variables are monitored from the alarm data learning, and qualitative and quantitative characterization of the correlation relations is carried out by utilization of the bayesian network ; fourthly, the obtained bayesian network is employed to adjust an alarm network, the root reason causing alarm is positioned rapidly and alarm flooding is reduced. The purpose is that an alarm system management method based on the bayesian network is employed to optimize alarm network performances, alarm flooding is reduced as possible, and therefore the method helps people to position the root reason causing alarm rapidly and take steps.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

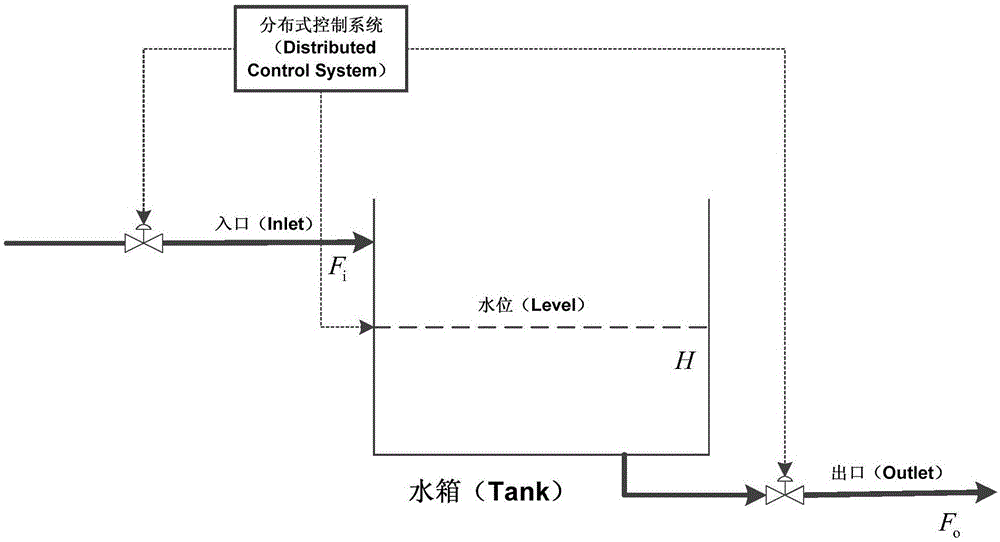

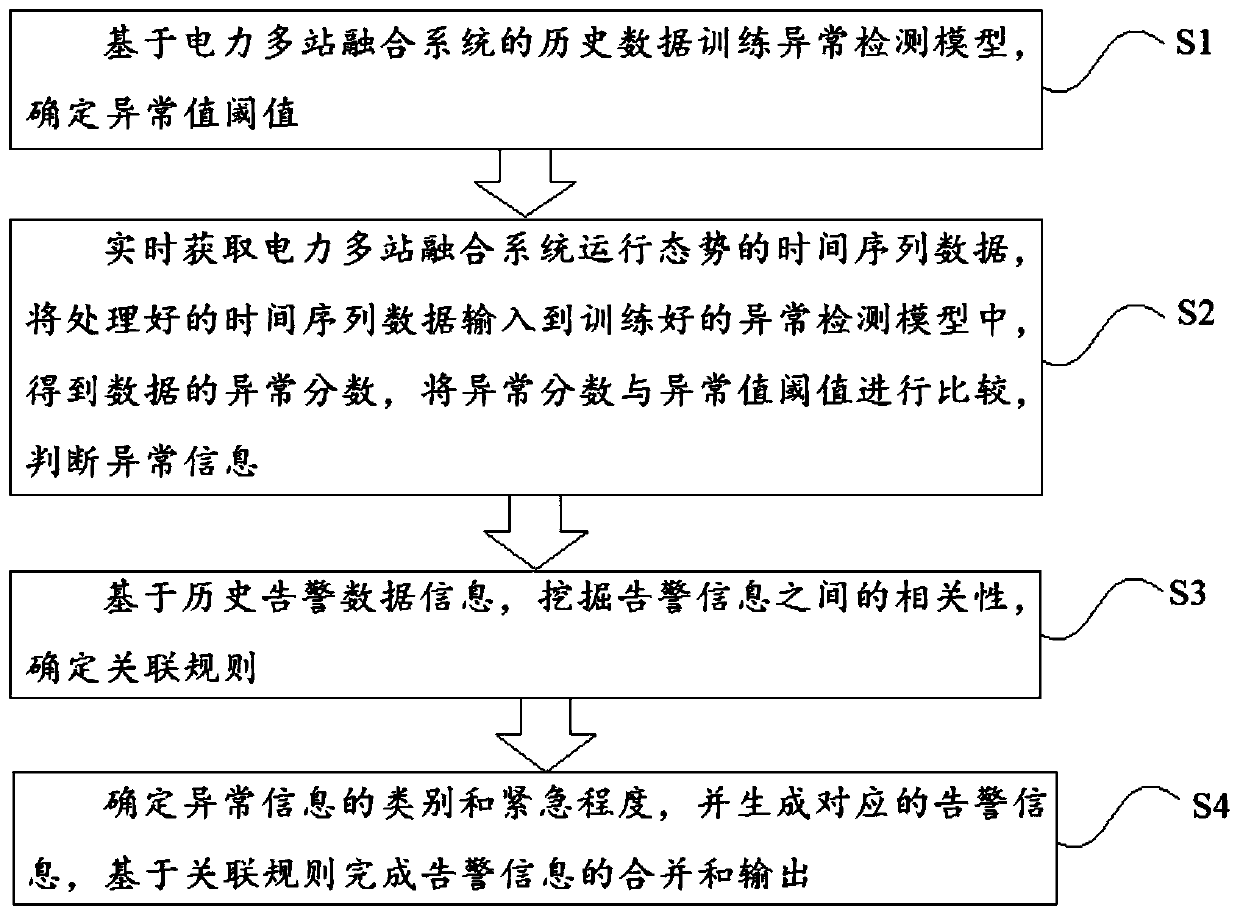

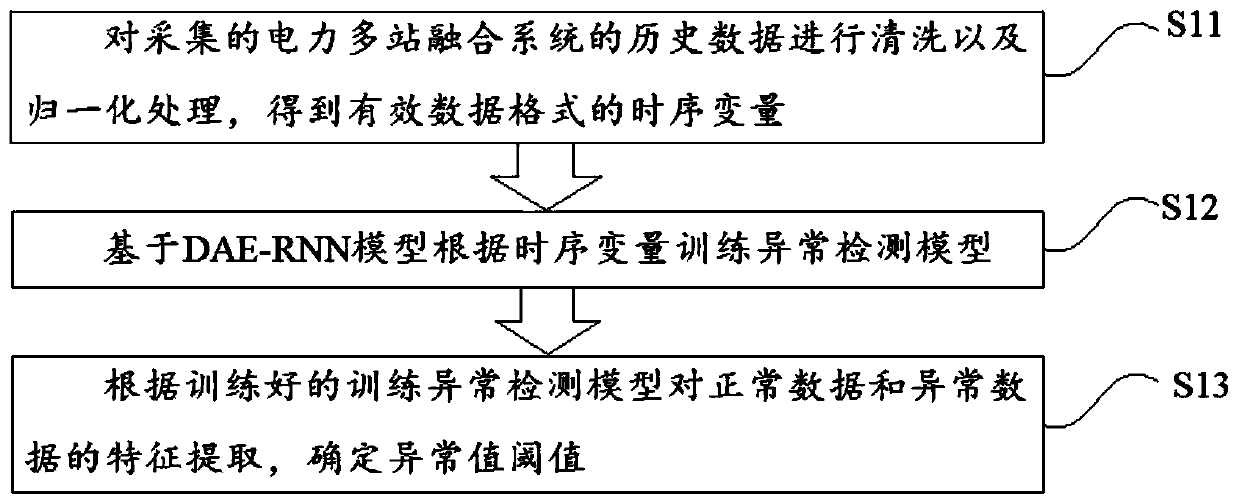

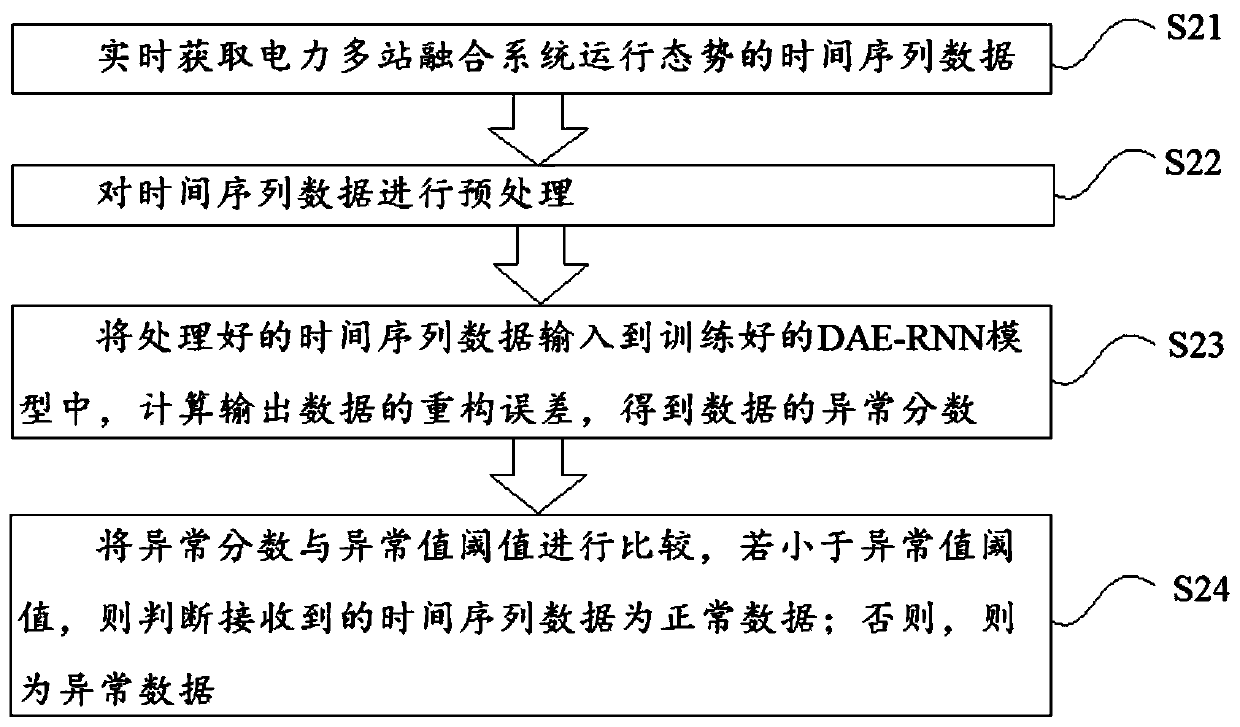

Multi-station fusion system operation situation anomaly monitoring and alarm merging method

InactiveCN111563524ASolve the noise problemImpact detectionData processing applicationsCircuit arrangementsAnomaly detectionPower grid

The invention relates to the field of intelligent power grids, in particular to a multi-station fusion system operation situation anomaly monitoring and alarm merging method, which comprises the stepsof training an anomaly detection model based on historical data of a power multi-station fusion system, and determining an abnormal value threshold; obtaining time sequence data of the operation situation of the power multi-station fusion system in real time, inputting the processed time sequence data into a trained anomaly detection model to obtain an anomaly score of the data, comparing the anomaly score with an anomaly value threshold, and determining anomaly information; based on the historical alarm data information, mining the correlation between the alarm information, and determining an association rule; and determining the category and the emergency degree of the anomaly information, generating corresponding alarm information, and completing combination and output of the alarm information based on the association rule. According to the invention, combination and output of alarm information are realized, and effective detection of anomaly data in time series data in operation and maintenance of the power multi-station fusion system is realized.

Owner:NINGBO TRANSMISSION & DISTRIBUTION CONSTR +4

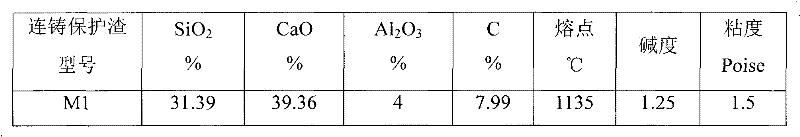

A method to match the low-speed pouring of extra-thick slab and the consumption of mold flux in continuous casting

The invention relates to a method for matching low-speed pouring of an ultra-thick plate blank with consumption of continuous casting powder and belongs to the technical field of continuous casting powder of a steelmaking continuous casting crystallizer. The method comprises the following steps: by aiming at the carbon content of 0.15-0.2wt% in the medium carbon steel made of a 400mm ultra-thick plate blank, controlling the content of SiO2 in the continuous casting powder within a range of 28-34wt%, controlling the content of CaO within a range of 35-40wt%, controlling the content of Al2O3 within a range of 3.5-4wt%, controlling the alkalinity within a range of 1.25-1.26, controlling the viscosity within a range of 1.4-1.5 Poise, controlling the content of carbon within a range of 7.5-8wt% and controlling the melting point within a range of 1100-1130 DEG C, thereby being beneficial to increasing the consumption of the continuous casting powder; and meanwhile, according to practical production requirements, when a pouring speed of a plate blank is 0.7m / min, controlling the vibration frequency within a range of 145-155cpm, controlling the vibration amplitude within a range of 4.5-5.0mm and controlling the negative slip time within a range of 0.09-0.12s, thereby acquiring the consumption of continuous casting powder being 0.55-0.60kg / m<2> and the actual measured melt cinder thickness being 10-13mm. The method provided by the invention has the advantage that the balance between the consumption of continuous casting powder and the melting speed is effectively controlled.

Owner:SHOUGANG CORPORATION

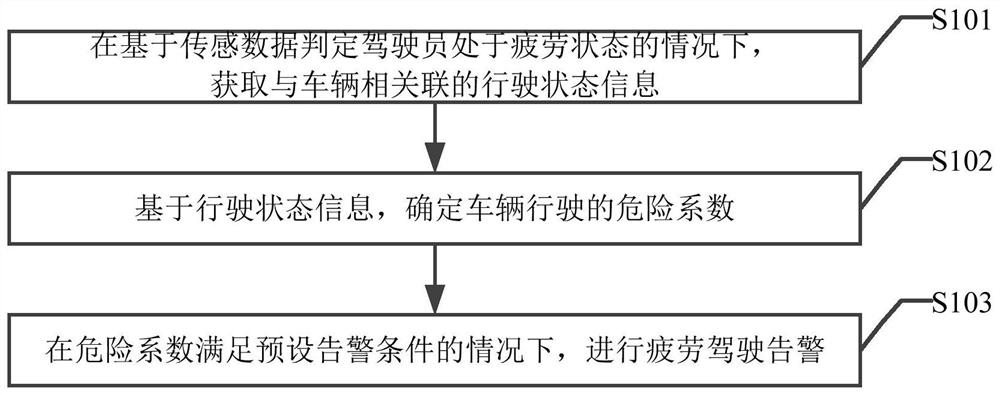

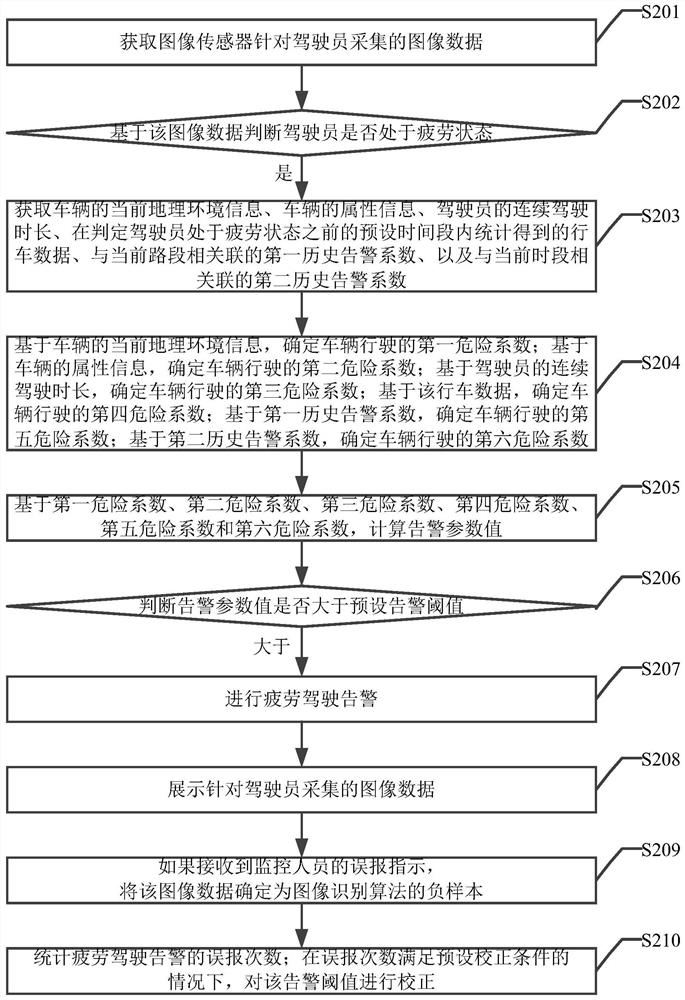

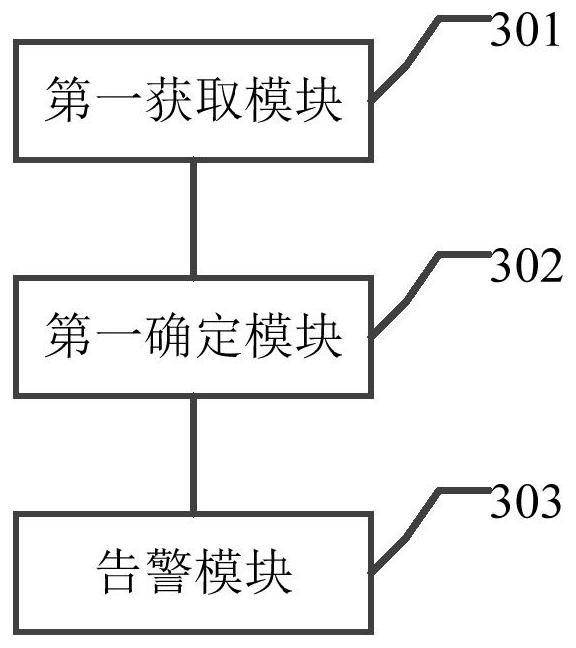

Fatigue driving warning method, device and equipment

ActiveCN112102586AReduce the number of alarmsReduce adverse effectsRegistering/indicating working of vehiclesCharacter and pattern recognitionDriver/operatorVehicle driving

The embodiment of the invention provides a fatigue driving alarm method, device and equipment, and the method comprises the steps: continuing to obtain the driving state information associated with avehicle instead of immediately giving a fatigue driving alarm under the condition that a driver is judged to be in a fatigue state; determining a danger coefficient of vehicle driving based on the driving state information; under the condition that the danger coefficient meets the preset warning condition, carrying out fatigue driving warning. Therefore, on the first hand, the number of times of warning is reduced, and adverse effects caused by frequent warning are reduced; on the second hand, fatigue driving warning is conducted under the condition that the danger coefficient of the vehicle meets the preset warning condition, and the driving safety is improved.

Owner:HANGZHOU HIKVISION SYST TECH

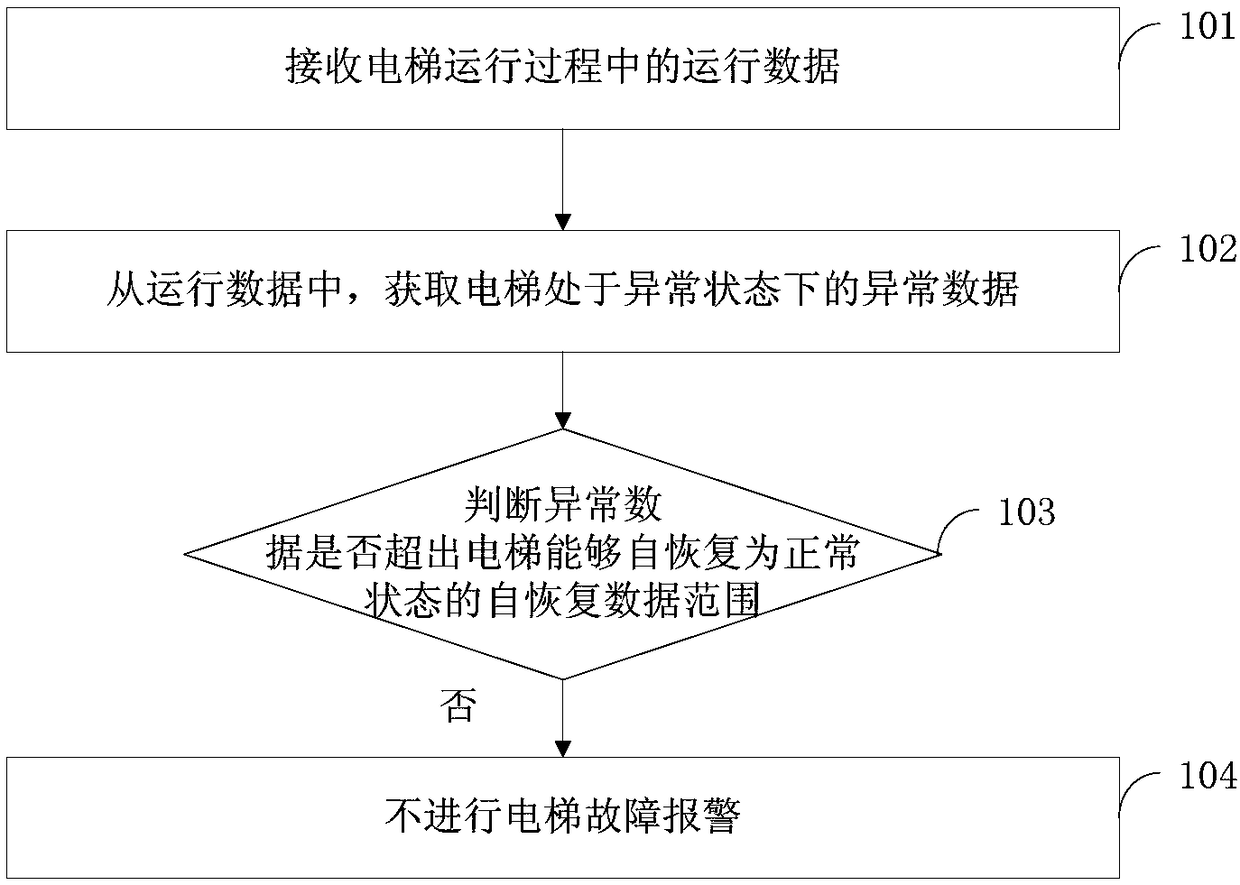

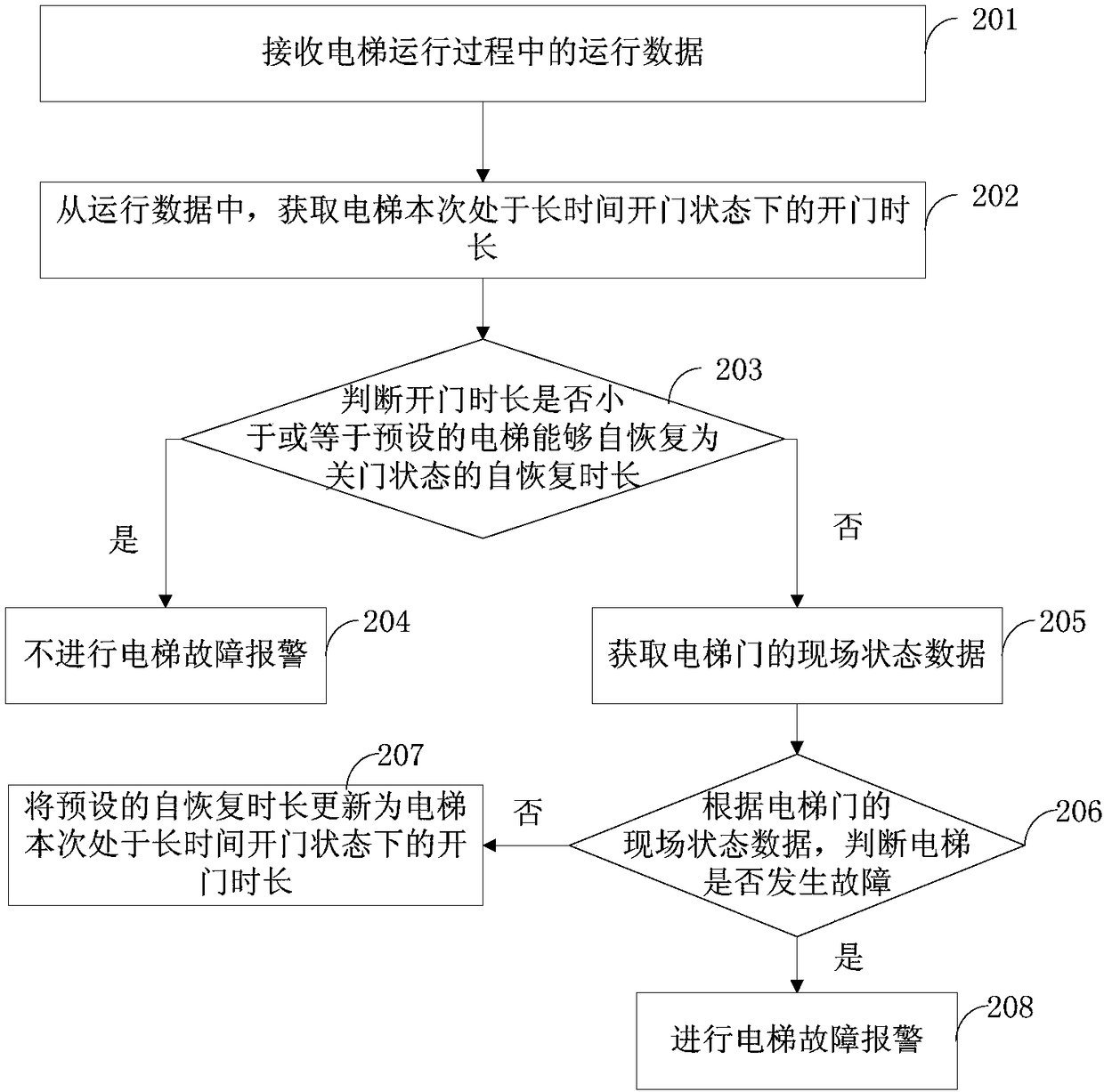

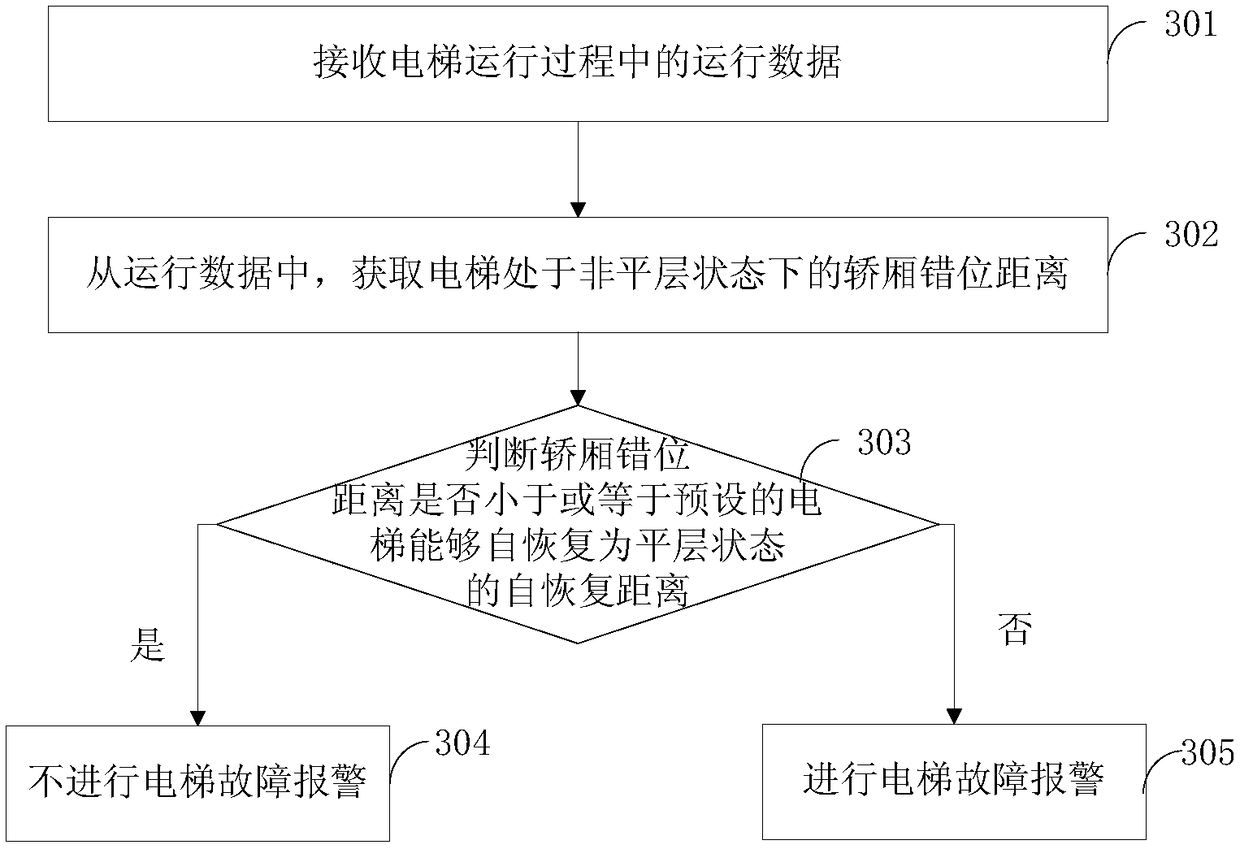

Elevator safety monitoring method, device, system and medium

ActiveCN108147246AReduce the number of alarmsReduce false alarm rateElevatorsSelf recoveryFalse alarm

The embodiment of the invention discloses an elevator safety monitoring method, device, system and medium. The method comprises the steps that operation data in the operation process of an elevator are received; the abnormal data of the elevator in an abnormal state are obtained from the operation data; and if the abnormal data do not exceed the self-recovery data range within which the elevator can be recovered to be the normal state independently, an elevator fault alarm is not given. By means of the elevator safety monitoring method, device, system and medium, the false alarm rate of the elevator can be effectively lowered, and accuracy of elevator alarming is improved.

Owner:南京博纳睿通软件科技有限公司

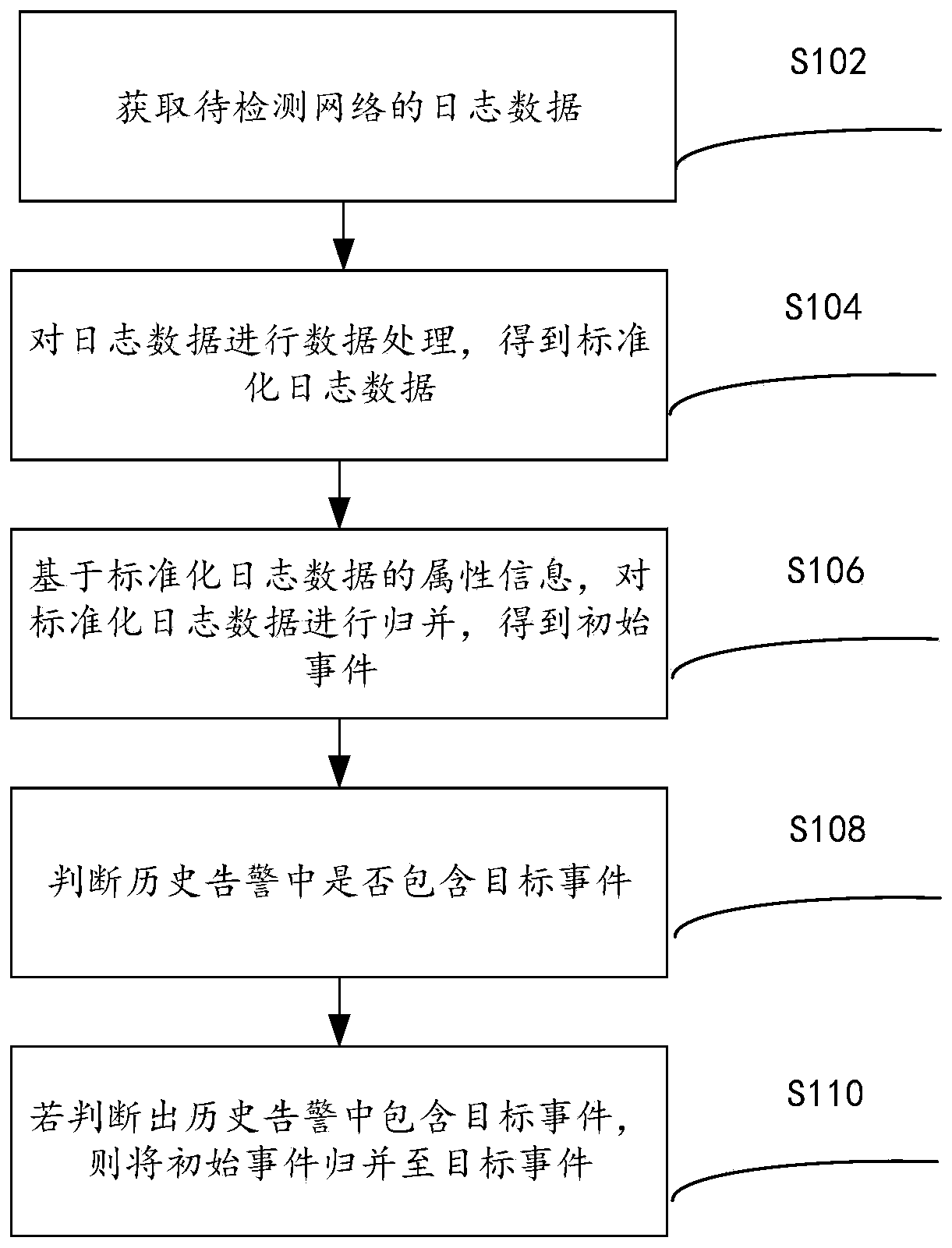

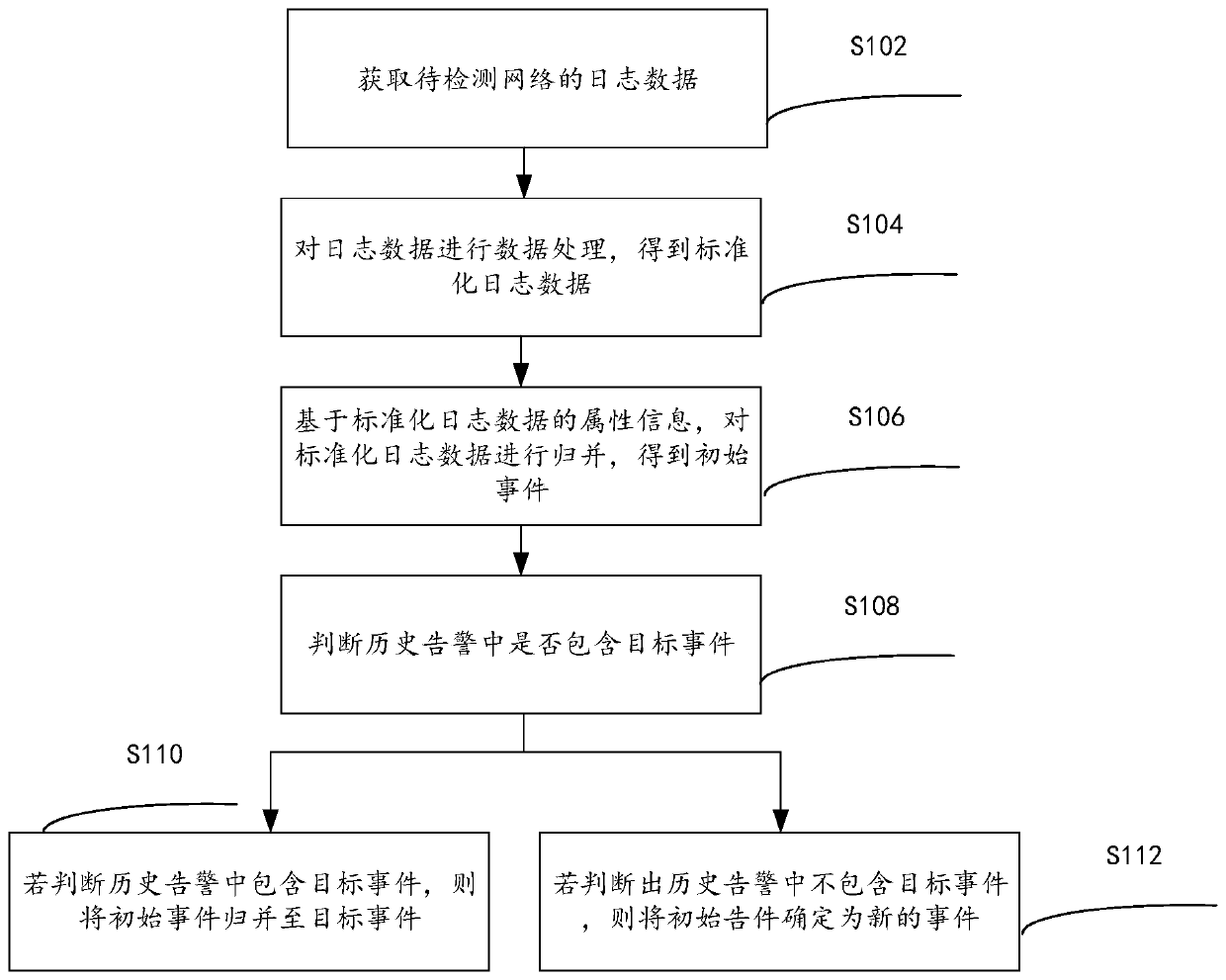

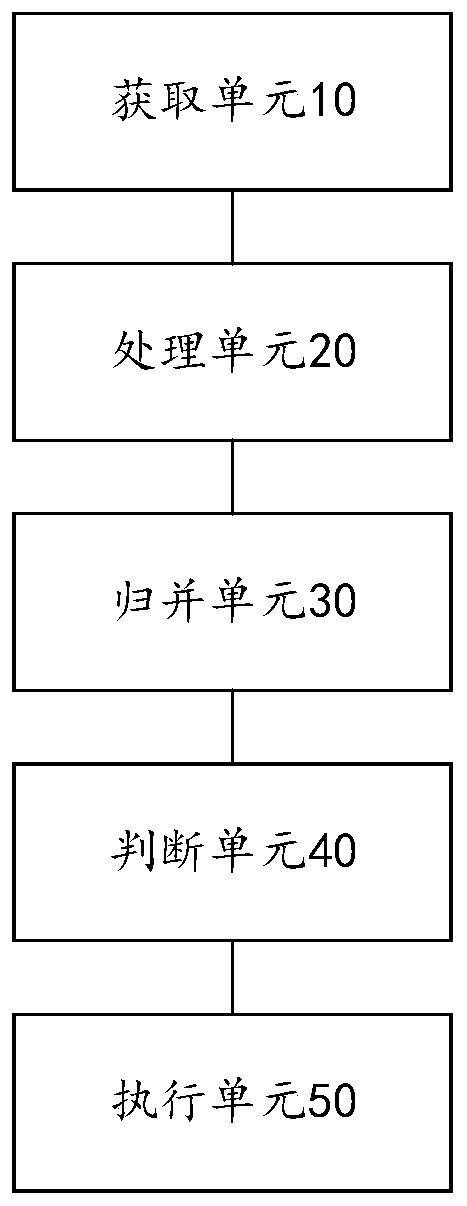

Threat alarm generation method and device based on systematic attacks

InactiveCN110677287AReduce duplicate alertsReduce the number of alarmsData switching networksAttackEngineering

The invention provides a threat alarm generation method and device based on systematic attacks, and relates to the technical field of network security, and the method comprises the steps: obtaining log data of a to-be-detected network; performing data processing on the log data to obtain standardized log data; merging the standardized log data based on the attribute information of the standardizedlog data to obtain an initial event; judging whether the historical alarm contains a target event or not; and if it is judged that the historical alarm contains the target event, merging the event tothe target event, thereby solving the technical problem that a large number of attack alarms can be generated for advanced sustainable attacks in the prior art.

Owner:HANGZHOU ANHENG INFORMATION TECH CO LTD

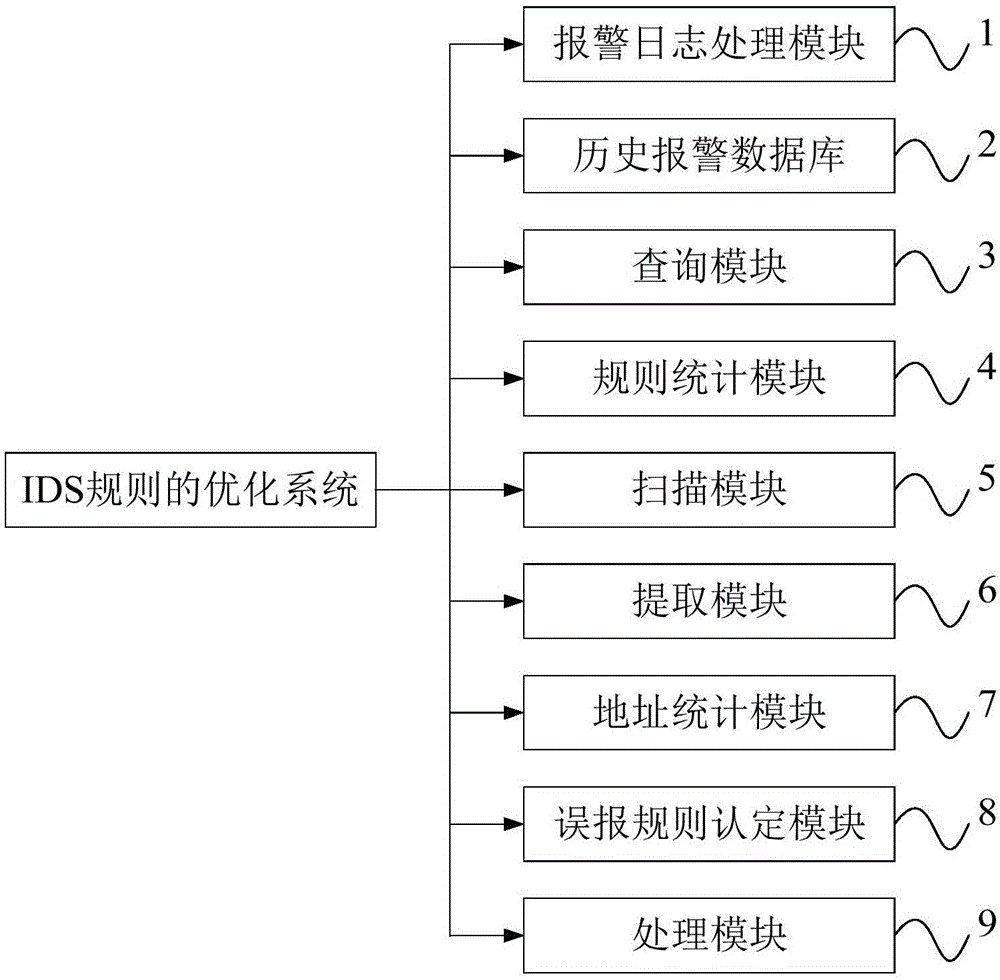

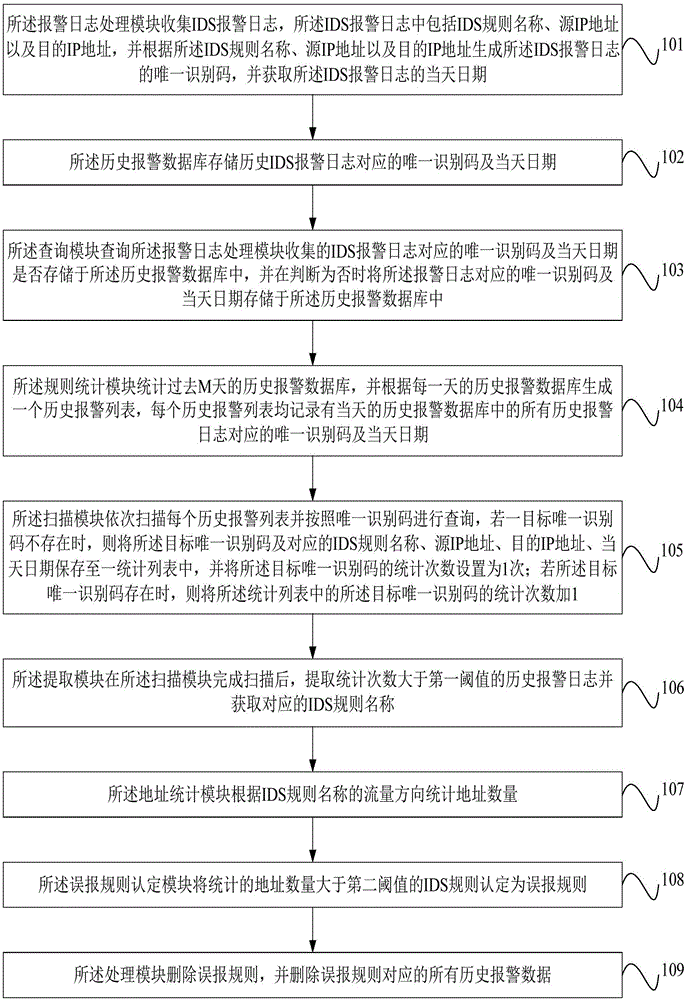

IDS rule optimization system and optimization method

ActiveCN106446720AImprove accuracyImprove usabilityInternal/peripheral component protectionData miningFalse alarm

The invention discloses an IDS rule optimization system and optimization method. The optimization system comprises an alarm log processing module which collects IDS alarm logs, generates unique identification codes and obtains a date of that day, a historical alarm database which stores historical IDS alarm logs, a query module which queries whether the collected IDS alarm logs are stored in the historical alarm database or not and performs storage if the collected IDS alarm logs are not stored in the historical alarm database, a rule statistics module which performs statistics on the historical alarm database of the past M days and generates M historical alarm lists, a scanning module which scans each historical alarm list and performs a query, an extraction module which extracts historical alarm logs, of which a statistic frequency is higher than a first threshold, and obtains an IDS rule name, an address statistics module which performs statistics on an address quantity according to a flow direction, a false alarm rule identification module which identifies an IDS rule, in which the address quantity subjected to the statistics is greater than a second threshold, as a false alarm rule, and a processing module which deletes the false alarm rule. According to the system and the method, the alarm quantity is reduced, so that the alarm accuracy is improved.

Owner:SHANGHAI CTRIP COMMERCE CO LTD

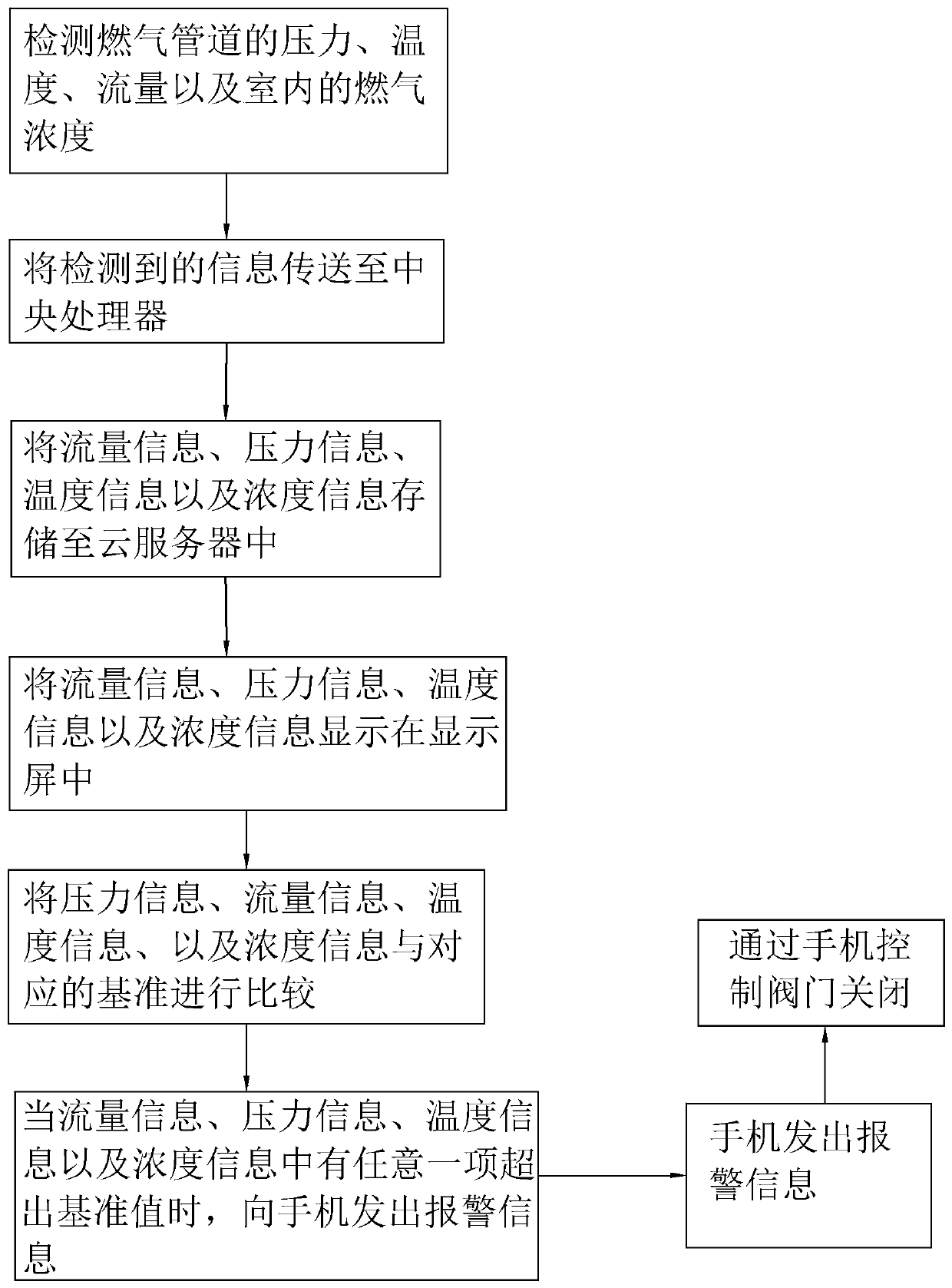

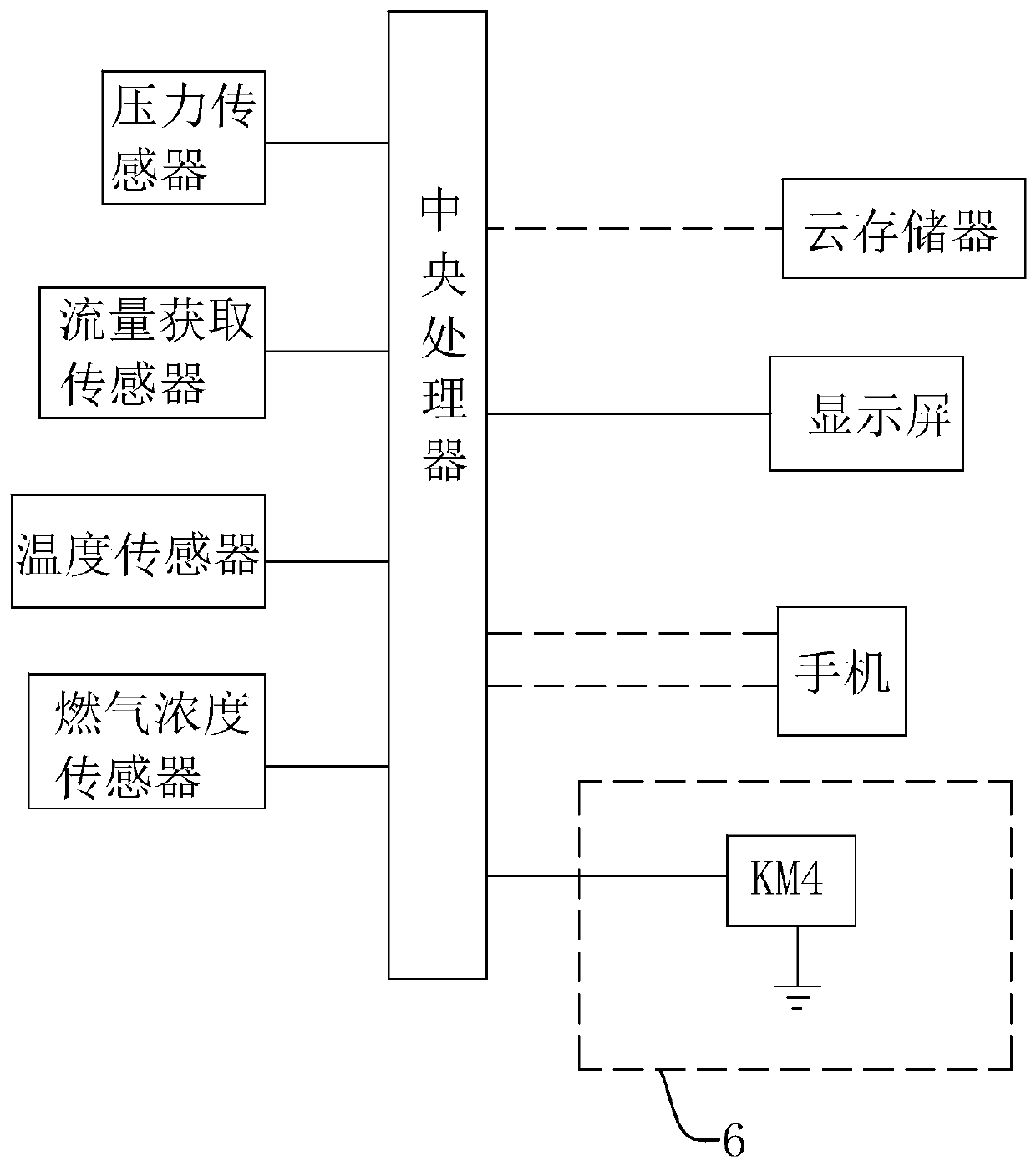

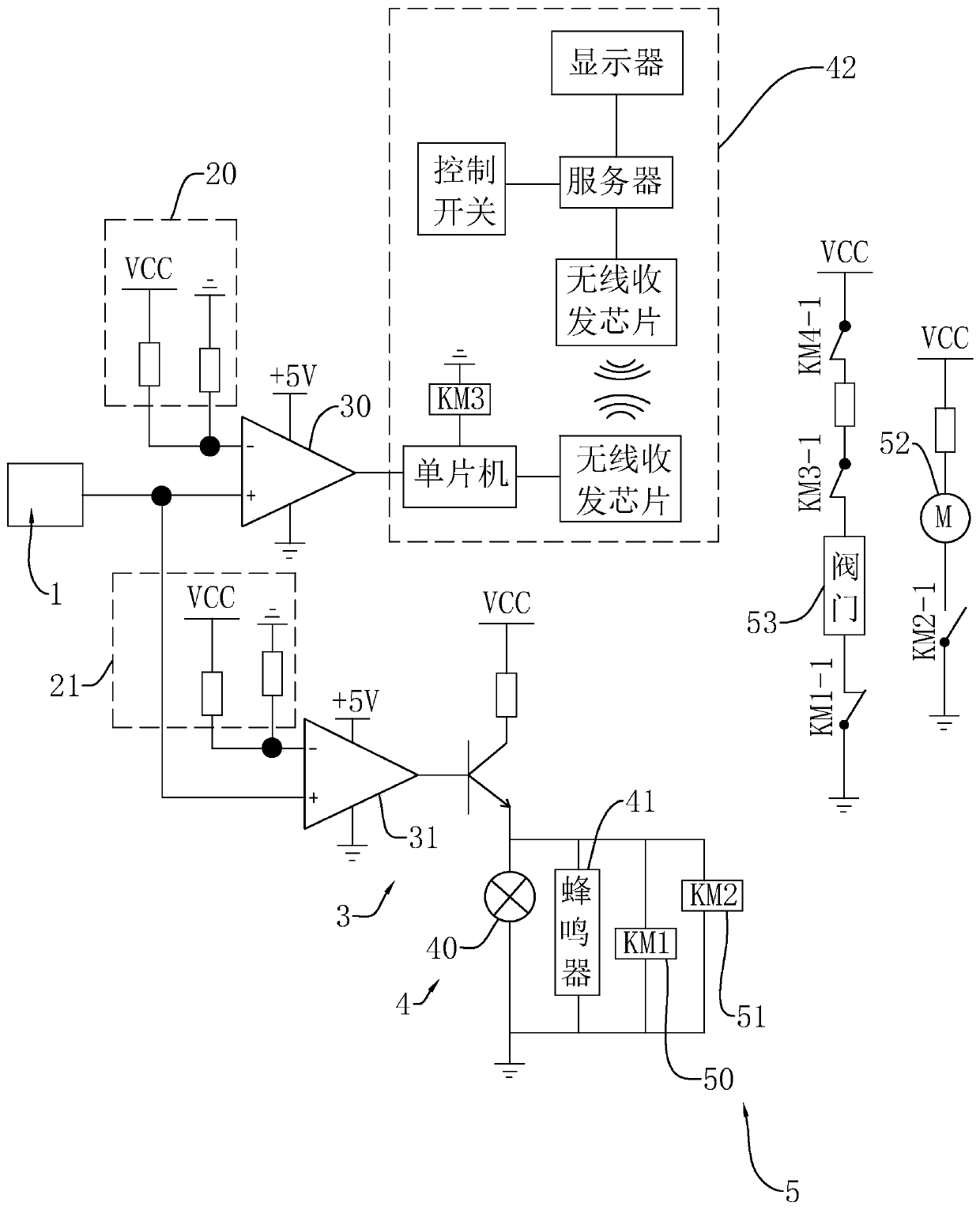

Data processing systme based on cloud intelligent gateway

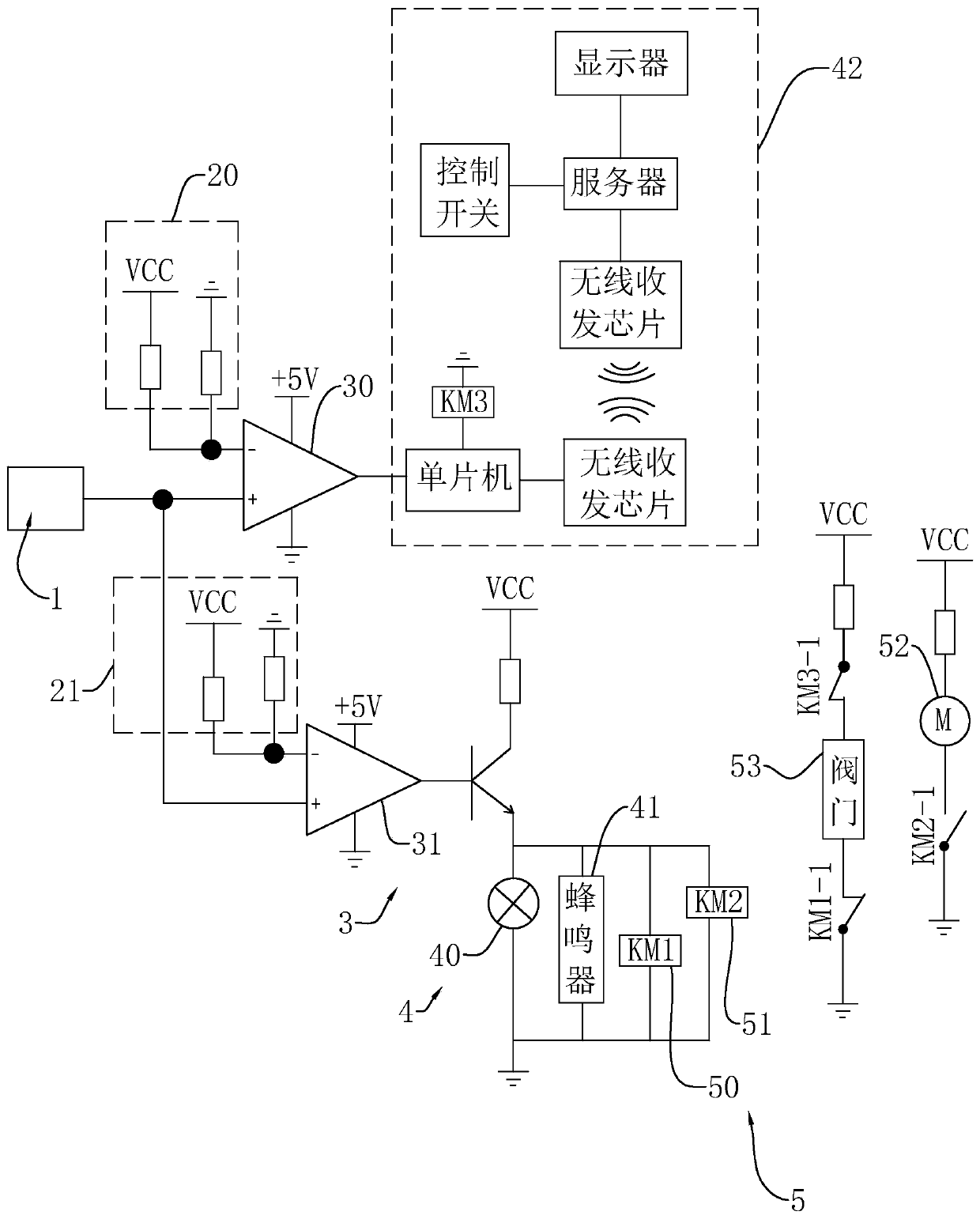

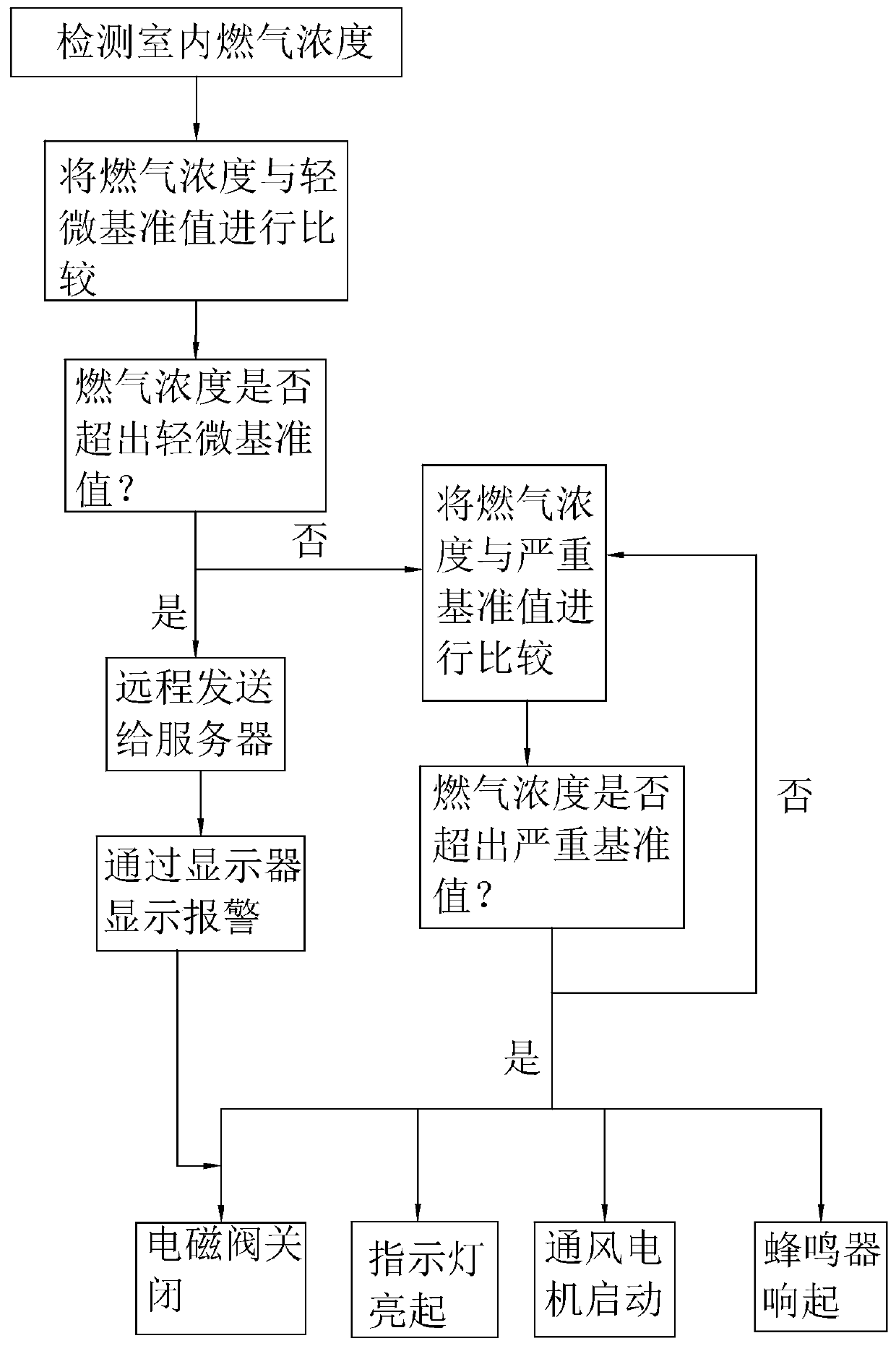

InactiveCN110648506AShorten the timeTimely responseValve arrangementsAlarmsControl cellExecution control

The invention discloses a data processing system based on a cloud intelligent gateway and relates to the technical field of valve control. According to key points of the technical scheme of the invention, the data processing system comprises a data detection system used for detecting any one or more or multiple combinations of pressure, flow and temperature in a gas pipeline as well as indoor gasconcentration, an execution control system used for receiving data, namely any one or more or multiple combinations of the pressure, flow and temperature as well as the indoor gas concentration, and performing analytic processing on the data, a cloud storage which is connected with the execution control system and used for storing the data, namely any one or more or multiple combinations of the pressure, flow and temperature as well as the indoor gas concentration, and a control unit which is arranged on the execution control system and used for controlling opening and closing of the gas pipeline. The data processing system disclosed by the invention solves the technical problem that a danger can be easily caused by gas leakage and has the advantage that the danger caused by the gas leakage is reduced.

Owner:深圳市中燃科技有限公司

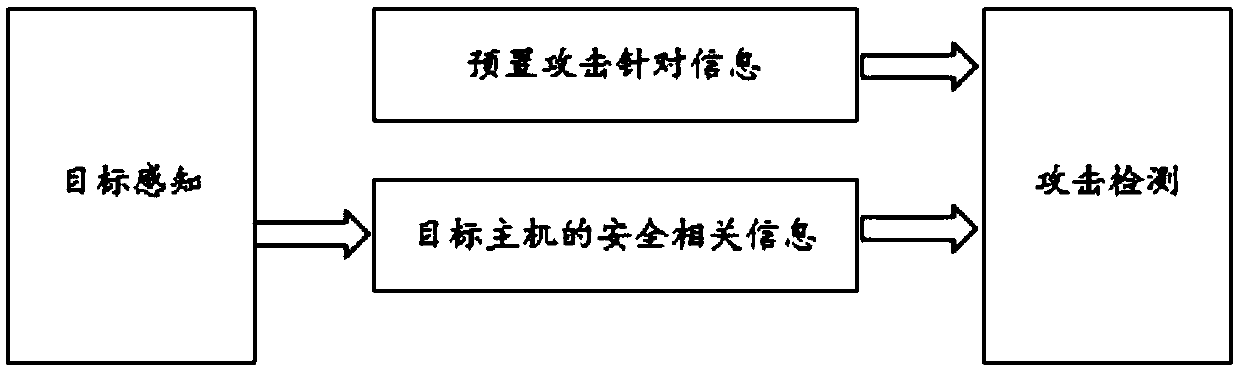

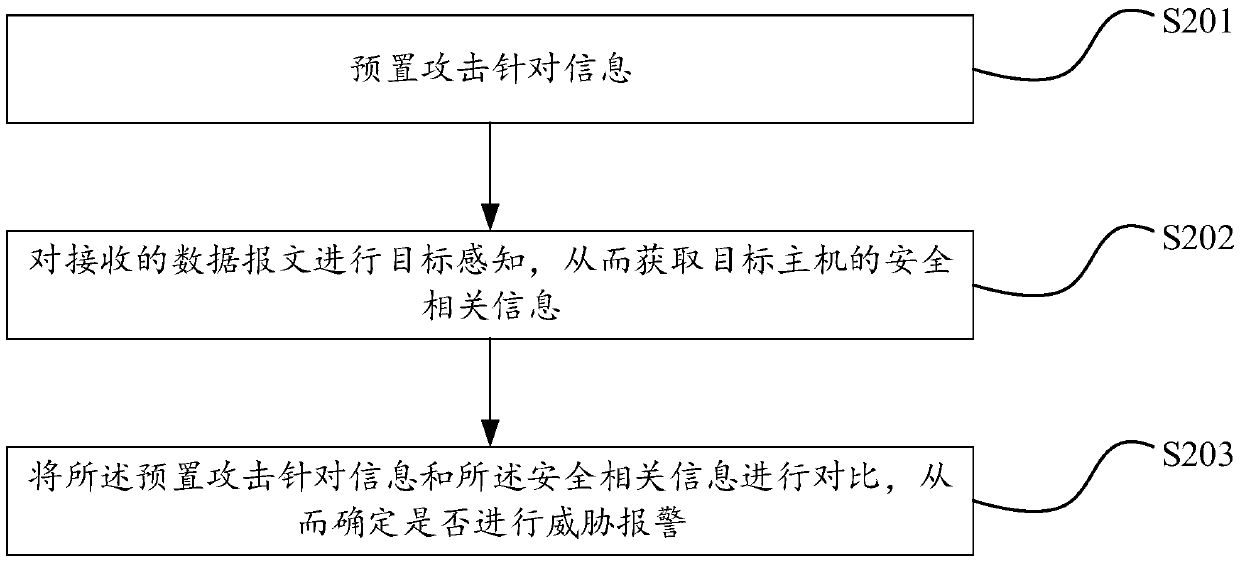

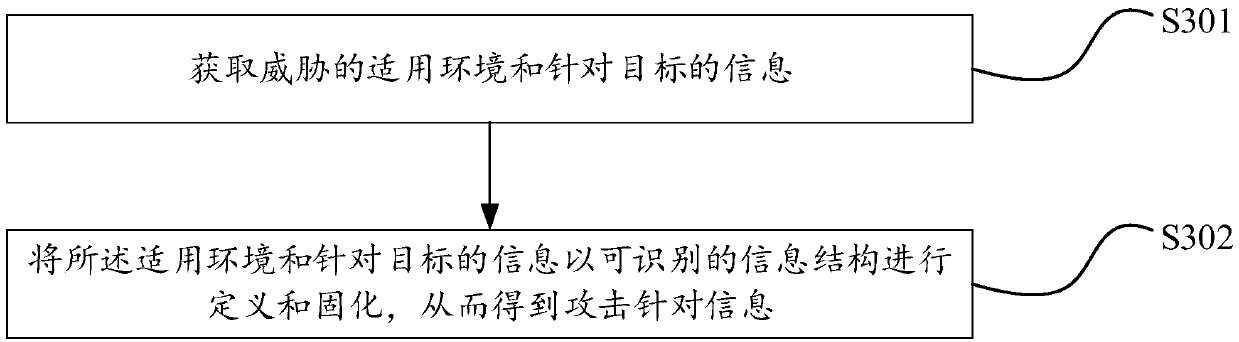

Threat alarm method, device and equipment via target perception

InactiveCN109587120AImprove effectivenessReduce the number of alarmsTransmissionRelevant informationInternet privacy

The invention discloses a threat alarm method, device and equipment via target perception. The method comprises that information aimed at attack is preset; target perception is carried out on a received data message, and security related information of a target host is obtained; and the preset attacked aimed information is compared with the security related information to determine whether to raise threat alarm. The preset attack aimed information is used to senses target threats in the network environment, the attack aimed information is compared with the security related information of target perception, and whether threat alarm is raised is determined according to a comparison result; and thus, alarm is reduced, threat alarm is more effective, possible omission is avoided, a user needsnot to log in the security related information of the protected host manually, instead, possible change of the security related information of the target host is adapted to automatically, and the method is easy to enforce and use and more practical.

Owner:BEIJING TOPSEC NETWORK SECURITY TECH +2

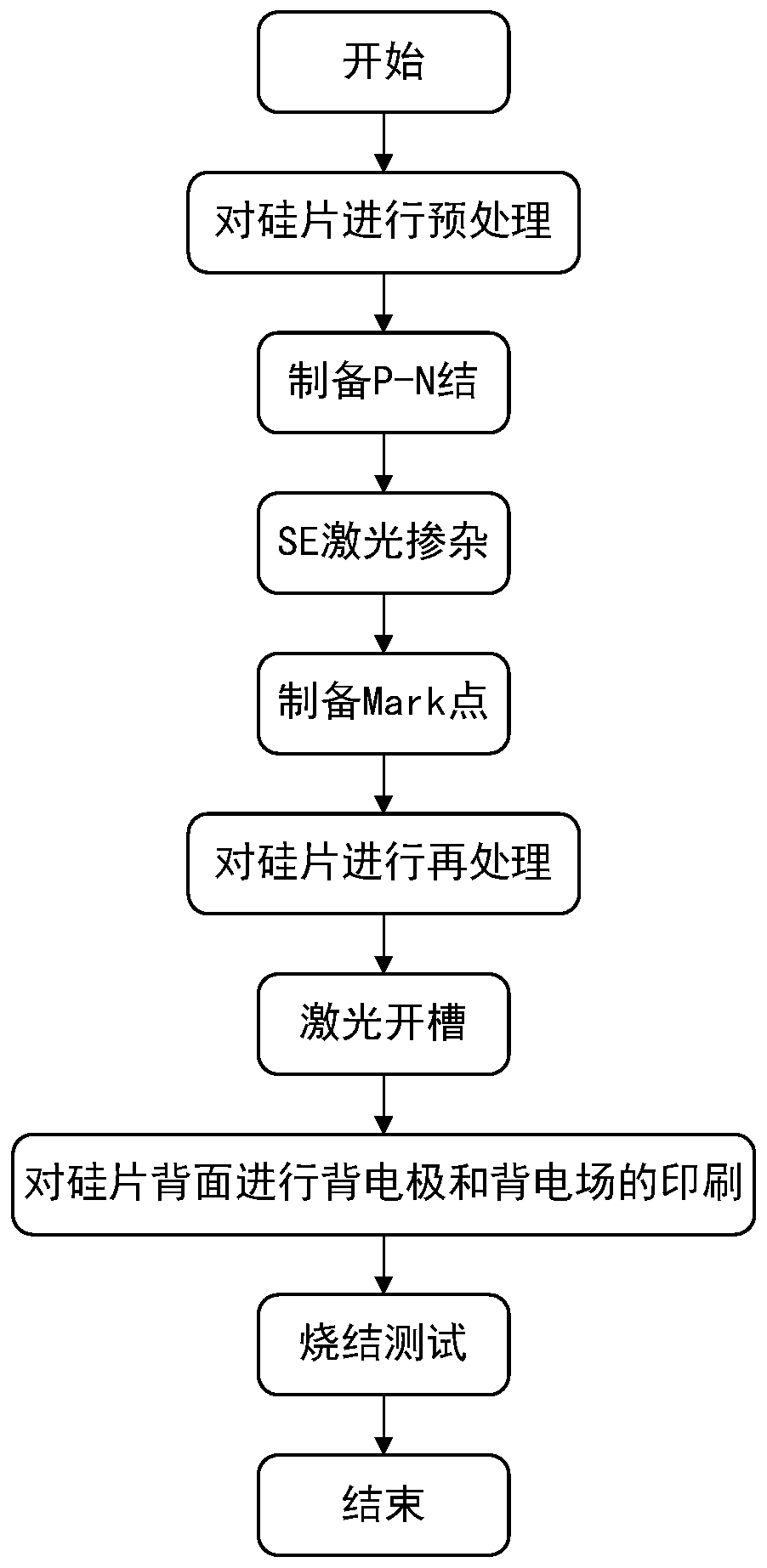

Novel SE Mark point graph structure and preparation method thereof

InactiveCN111370391AAvoid damageSimple processing technologyFinal product manufactureSemiconductor/solid-state device detailsGraphicsProcess engineering

The invention discloses a novel SE Mark point graph structure and a preparation method thereof. A purpose of the invention is to solve the problems of Mark point damage, high cost, low stability and long manufacturing time caused by secondary processing of the same area in a graph in the prior art. The novel SE Mark point graph structure comprises a silicon wafer body and a plurality of Mark points, wherein the Mark points are of a cross-shaped structure, and the Mark points are subjected to laser in the four corner areas of the silicon wafer body and used for a PERC superposition selective emitter technology. According to the invention, through the special Mark points, the production efficiency can be improved and the productivity can be improved in the production process, the number of device alarms is reduced, and the production time is greatly shortened; the preparation method is convenient for equipment identification, is good in stability in the industrial production process, andis completely compatible in equipment; and four cross-shaped Mark points are obtained through laser so as to achieve good alignment point morphology and convenient recognition, transverse lines and vertical lines cannot be overlapped for marking in the marking process, an equipment camera can conduct recognition more easily in the printing process, the number of times of alarming is reduced, andthe industrial production efficiency is effectively improved.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

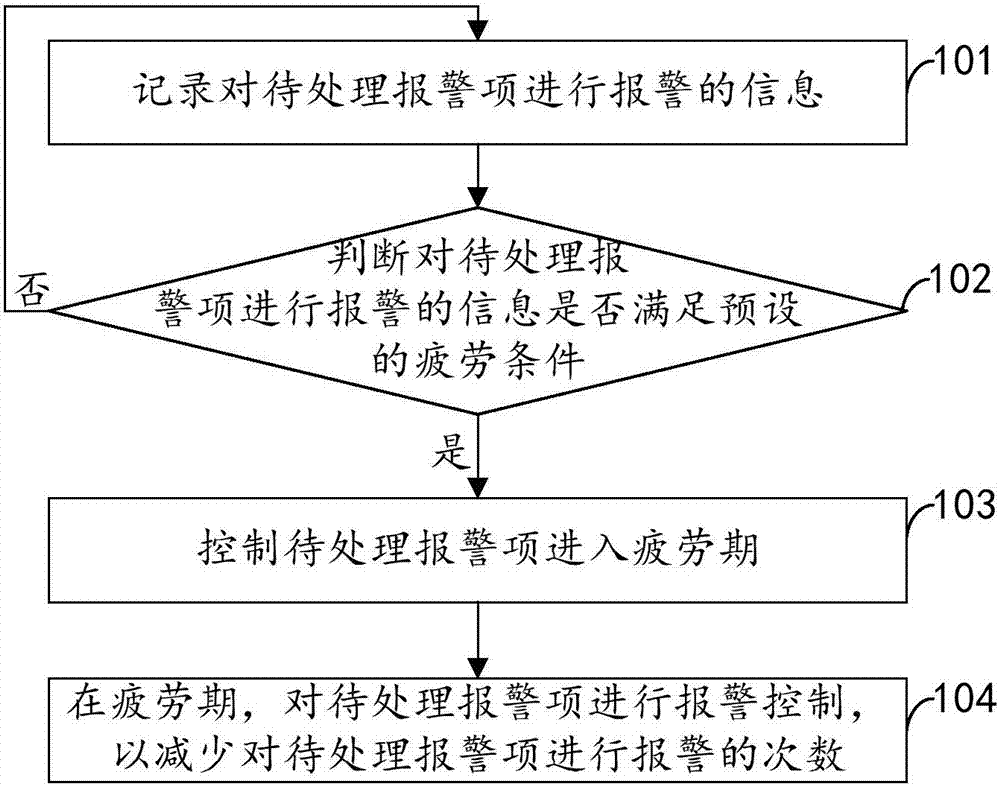

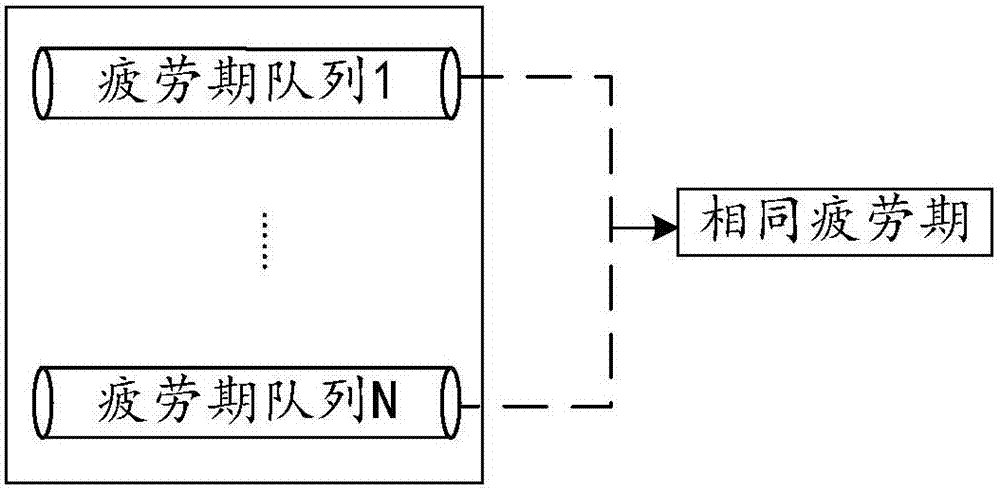

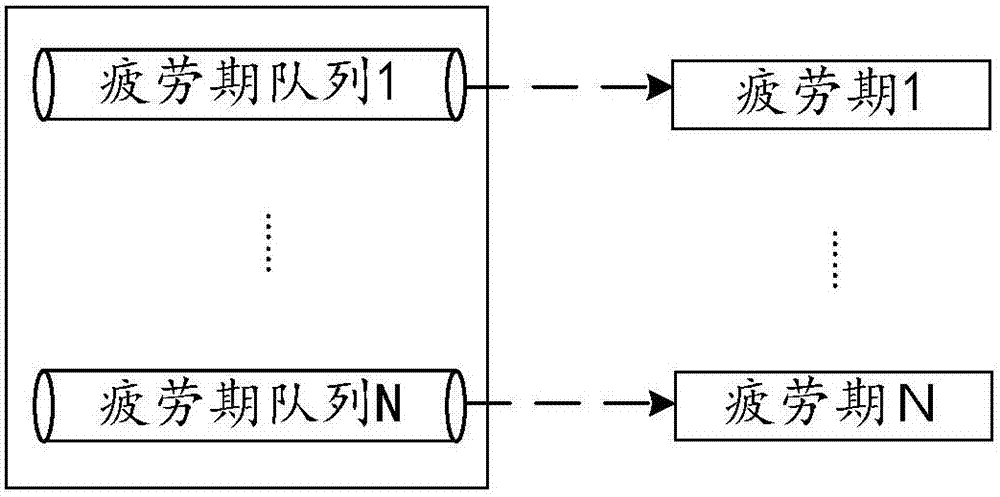

Abnormality monitoring alarming method and device

InactiveCN107241210AReduce the number of alarmsReduce distractionsData switching networksEngineering

The application provides an abnormality monitoring alarming method and device. The abnormality monitoring alarming method comprises the steps of: recording information of carrying out alarming on a to-be-processed alarm item; judging whether the information of carrying out alarming on the to-be-processed alarm item meets a preset fatigue condition; if a judgment result is yes, controlling the to-be-processed alarm item to proceed to a fatigue period; and in the fatigue period, carrying out alarm control on the to-be-processed alarm item so as to reduce times of carrying out alarming on the to-be-processed alarm item. According to the abnormality monitoring alarming method and device provided by the application, an abnormal case can be monitored and alarming can be properly carried out so as to benefit for saving resources consumed by abnormal alarming and reducing interference to an alarming object.

Owner:ALIBABA GRP HLDG LTD

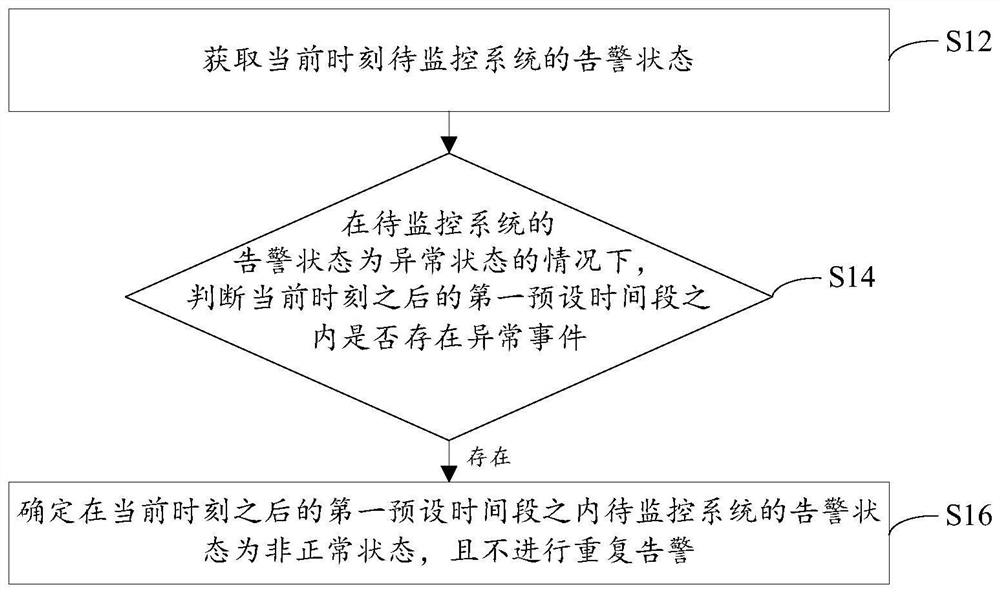

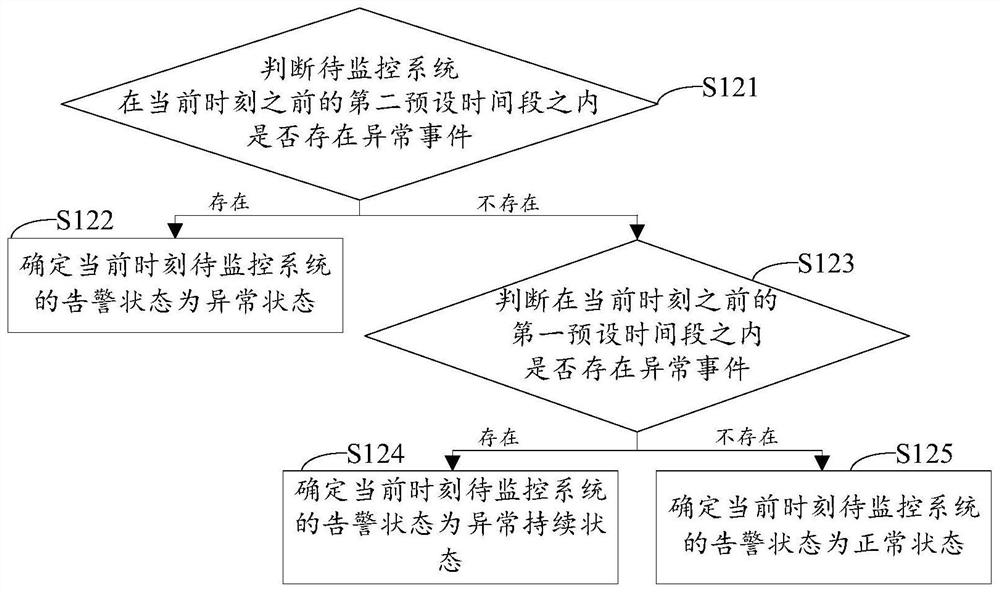

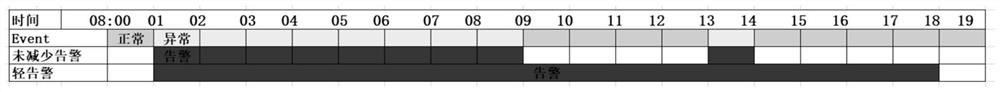

Alarm method and device and electronic equipment

PendingCN111782462AMitigate technical issues with high redundancyThe purpose of reducing the alarmHardware monitoringAlarm stateComputer science

The invention provides an alarm method and device, and electronic equipment, and relates to the technical field of monitoring, and the method comprises the steps of obtaining the alarm state of a to-be-monitored system at a current moment; under the condition that the alarm state of the to-be-monitored system is an abnormal state, judging whether an abnormal event exists within a first preset timeperiod after the current moment or not; and if so, determining that the alarm state of the to-be-monitored system is an abnormal state within a first preset time period after the current moment, andnot carrying out repeated alarm. The invention provides an alarm method. After the system to be monitored is in an abnormal state, whether the to-be-monitored system returns to a normal state or not is judged by taking a first preset time period as a time unit; even if abnormal events are discontinuous in the first preset time period, new alarm information cannot be triggered, the alarm frequencyis reduced, and therefore the technical problem that in the prior art, an alarm method is high in alarm information redundancy is effectively solved.

Owner:华青融天(北京)软件股份有限公司

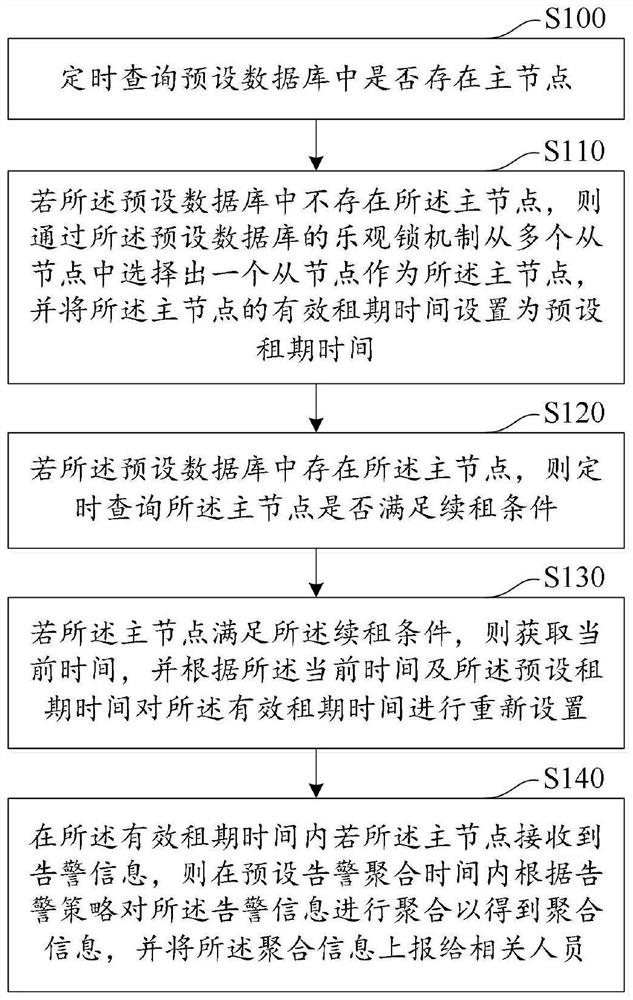

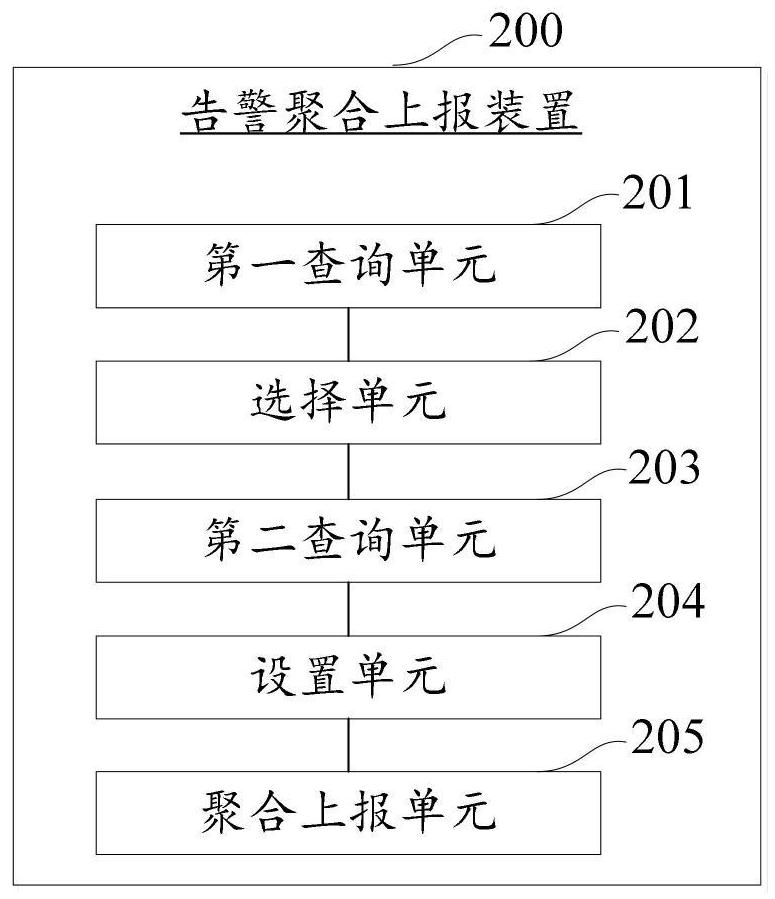

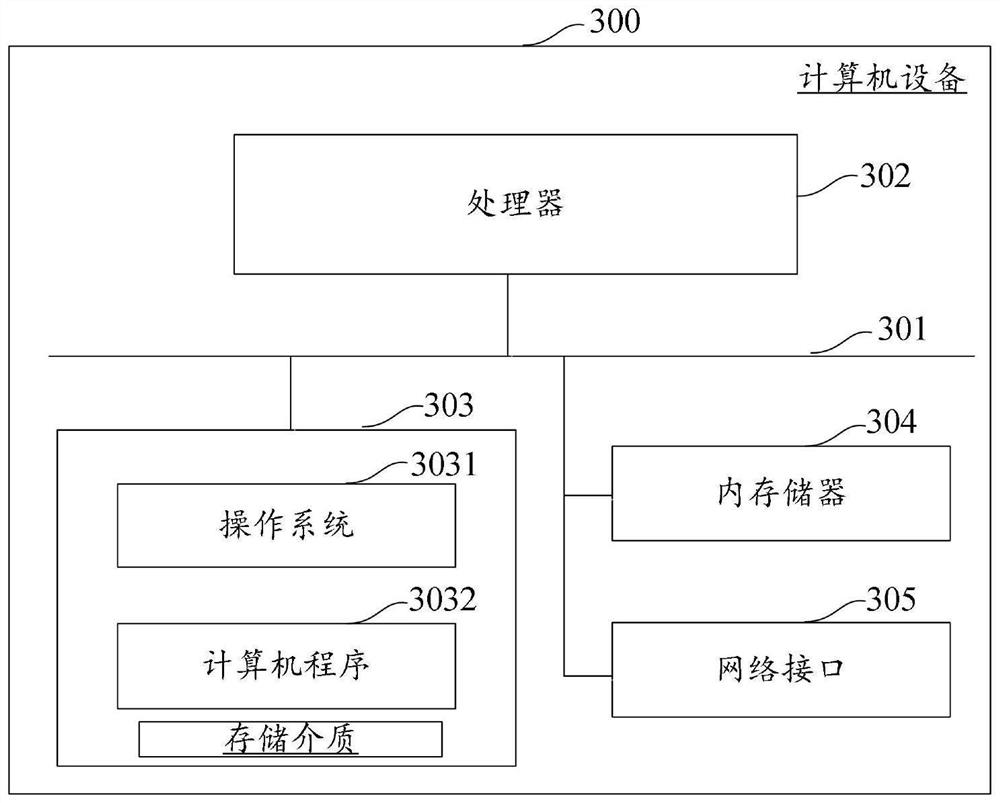

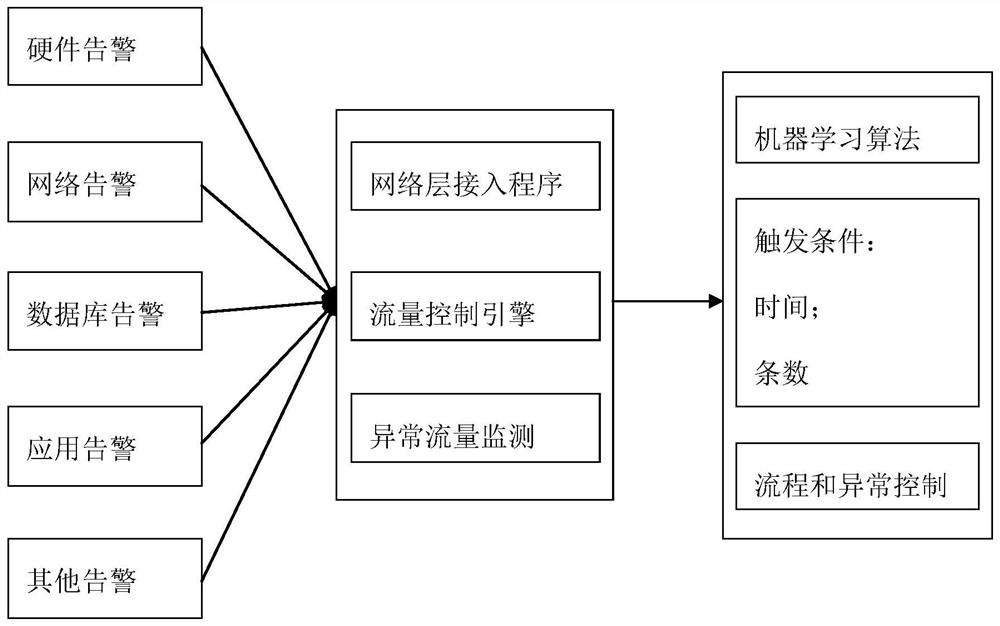

Alarm aggregation reporting method and device, computer equipment and storage medium

PendingCN114827168AReduce the number of alarmsImprove overall effectivenessDatabase queryingTransmissionComputer securityComputer equipment

The embodiment of the invention discloses an alarm aggregation reporting method and device, computer equipment and a storage medium. The invention relates to the technical field of alarm. The method comprises the following steps: regularly querying whether a main node exists in a preset database; if the master node does not exist in the preset database, one slave node is selected from the multiple slave nodes to serve as the master node through an optimistic lock mechanism of the preset database, and the effective tenancy time of the master node is set as the preset tenancy time; regularly inquiring whether the main node meets a lease renewing condition or not; if the main node meets the lease renewal condition, acquiring current time, and resetting the effective lease term according to the current time and the preset lease term; and if the main node receives the alarm information within the effective lease period, aggregating the alarm information according to an alarm strategy within a preset alarm aggregation time to obtain aggregated information, and reporting the aggregated information to related personnel. The embodiment of the invention can reduce the alarm frequency and improve the overall effectiveness of the alarm.

Owner:金腾科技信息(深圳)有限公司

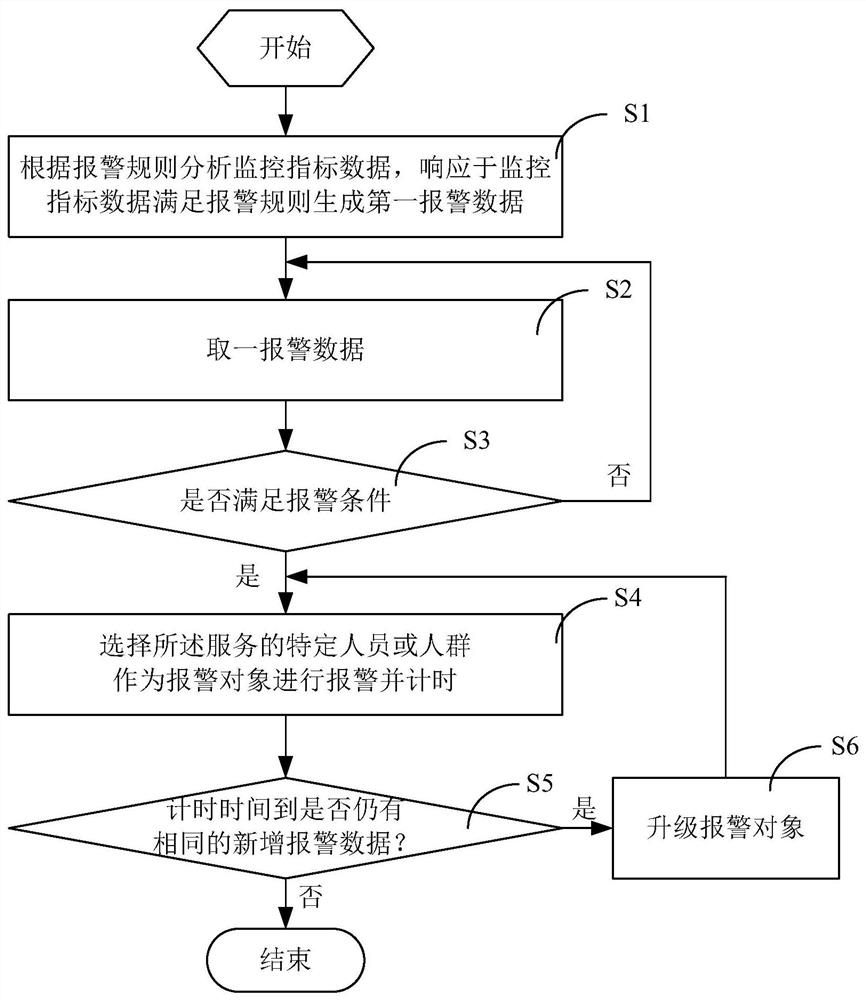

Alarm method and system of monitoring system

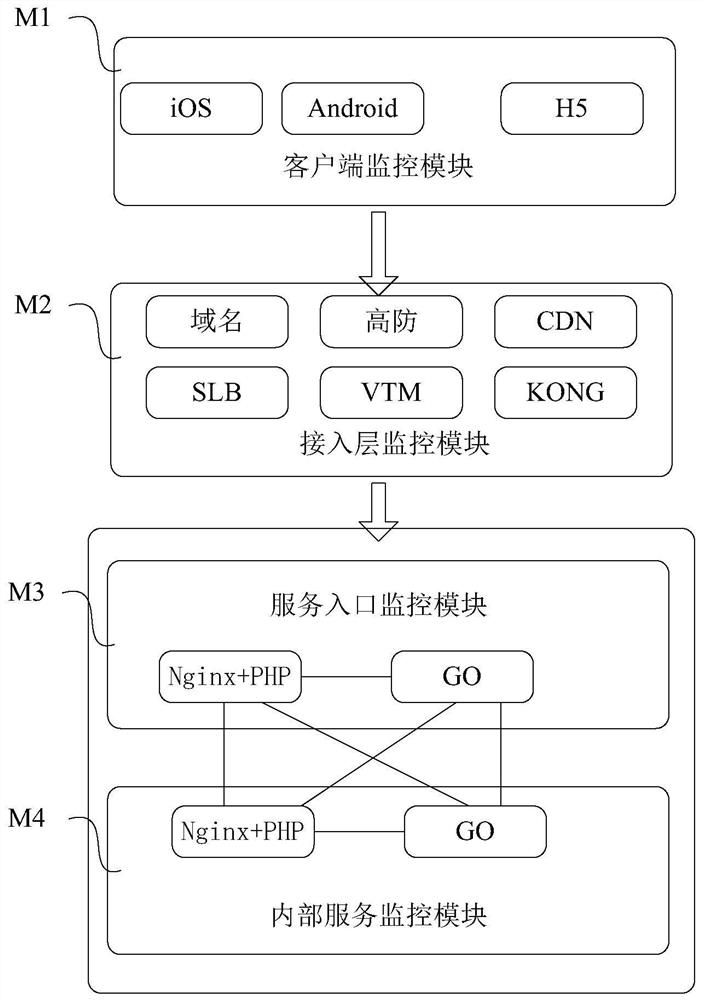

InactiveCN111983947AReduce the number of alarmsSpeed up alarm handlingProgramme controlComputer controlService selectionService oriented

The invention relates to an alarm method and system of a monitoring system, and the method comprises the steps: analyzing monitoring index data according to an alarm rule, generating first alarm datain response to a condition that the monitoring index data meets the alarm rule, and enabling the first alarm data to at least comprise a fault level, a hierarchical service identification and the monitoring index data; analyzing the alarm data, and when the alarm data meets an alarm condition, selecting specific personnel or crowds of the service as alarm objects to give an alarm according to thefault level of the alarm data and the service influenced by the alarm data; and the same newly added alarm data still exist in a preset time period after the alarm to upgrade the alarm object. According to the invention, service-oriented and business-oriented flow alarm is adopted, so that the number of alarms is reduced, and influenced services and fault points are determined. An automatic determination processing strategy mode is adopted, an existing communication tool is combined, different alarm strategies are set, alarm processing is accelerated through supervision measures, the fault processing efficiency is improved, and the application scene range is wide.

Owner:上海趣蕴网络科技有限公司

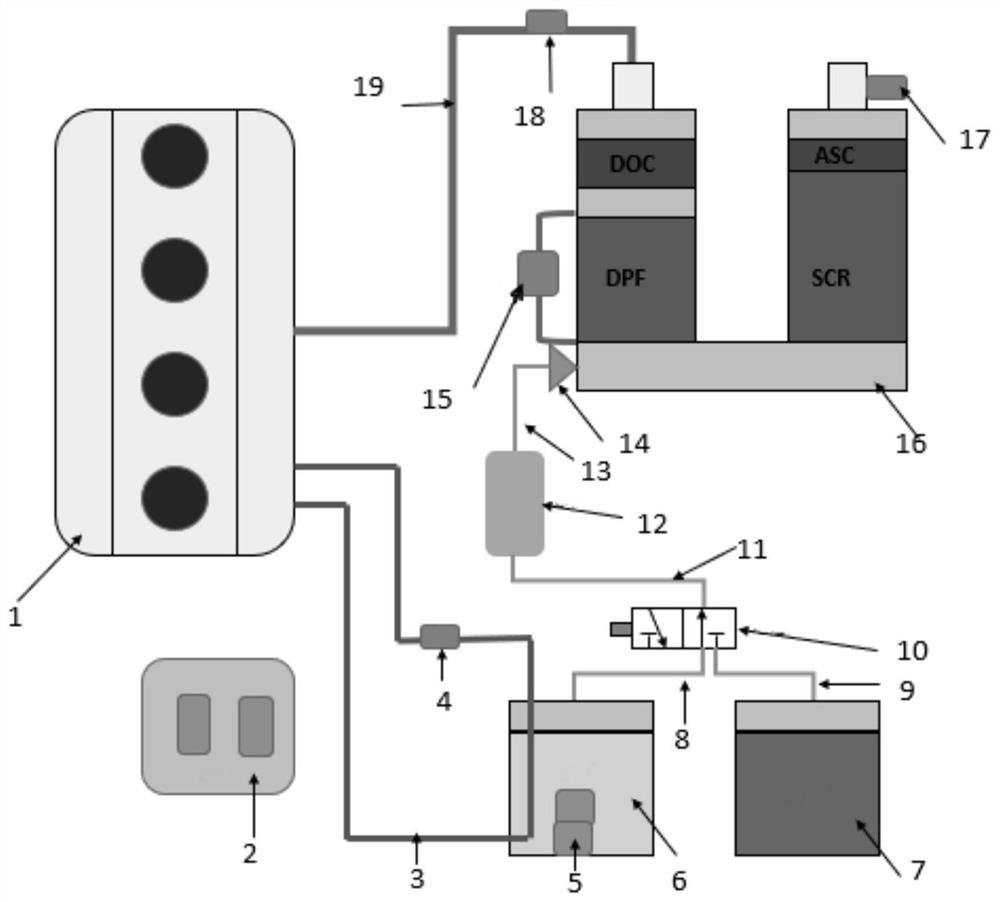

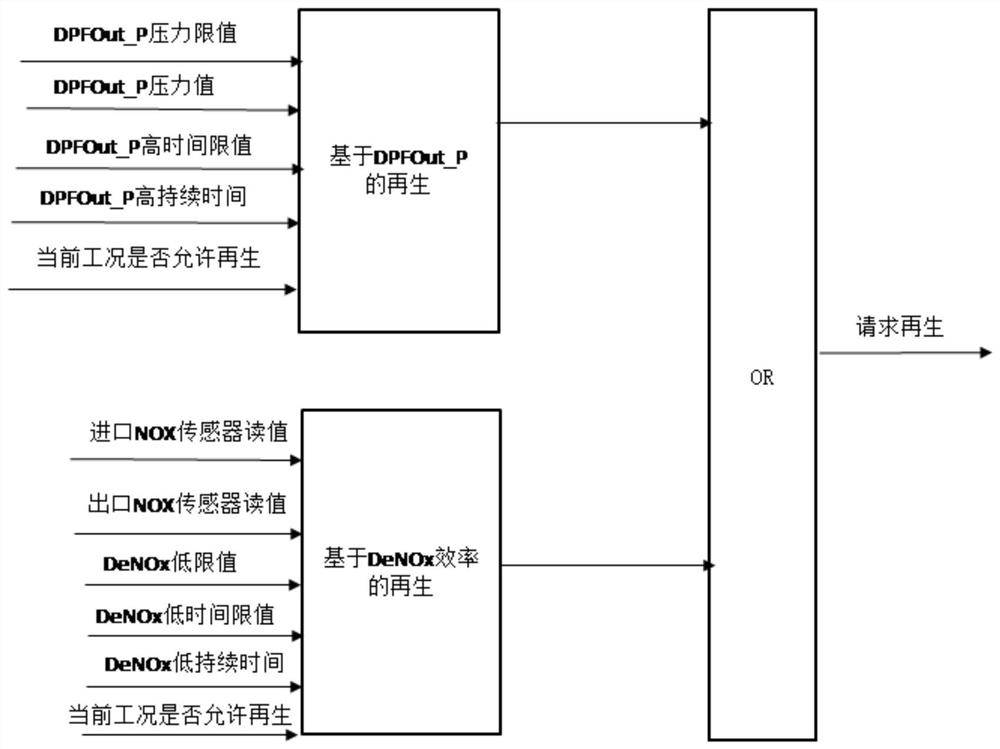

System and method for eliminating crystals of selective catalytic reduction system

ActiveCN111828136AEnables crystallization monitoringEliminate false positivesInternal combustion piston enginesExhaust apparatusPhysical chemistryCrystallization

The invention provides a method for eliminating the crystals of a selective catalytic reduction system, and belongs to the technical fields of engines and tail gas treatment. The method comprises thefollowing steps: monitoring the crystals in the selective catalytic reduction system in a normal working state; while monitoring the crystals in the selective catalytic reduction system, switching over the normal working state to a temporary working state; and executing elimination operation corresponding to the crystals in the temporary working state. The method is capable of monitoring the crystals in the SCR aftertreatment system; according to the method, the crystals in the SCR aftertreatment system are treated, the OBD alarming times caused by high NOX emission are reduced, and the timesof regeneration for activating SCR performance are reduced, so that engine oil dilution caused by multiple regenerations is prevented; and the method has the advantages of being simple in structure, low in cost, and good in use effect.

Owner:BEIJING FOTON CUMMINS ENGINE

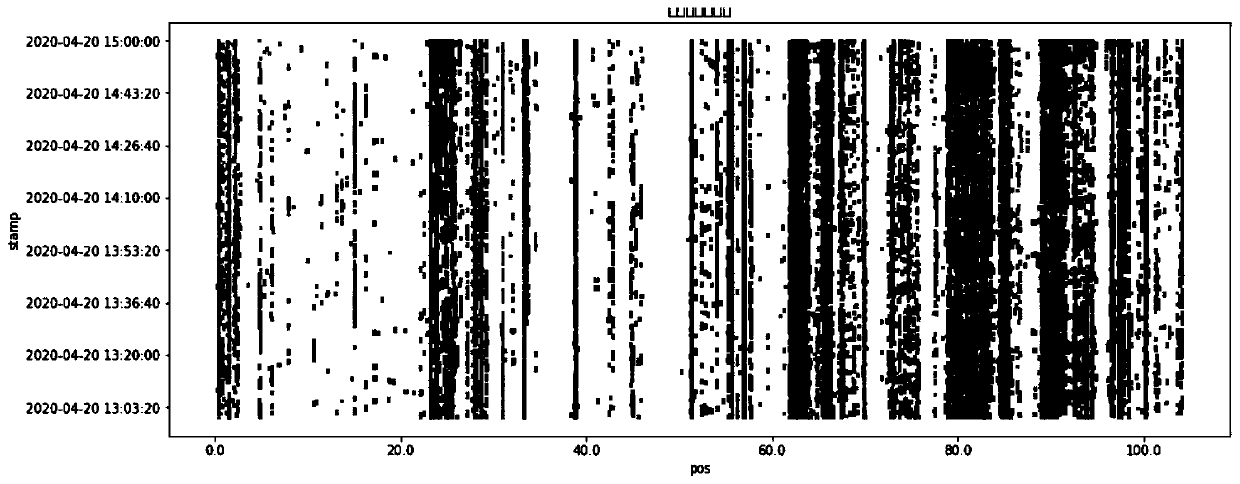

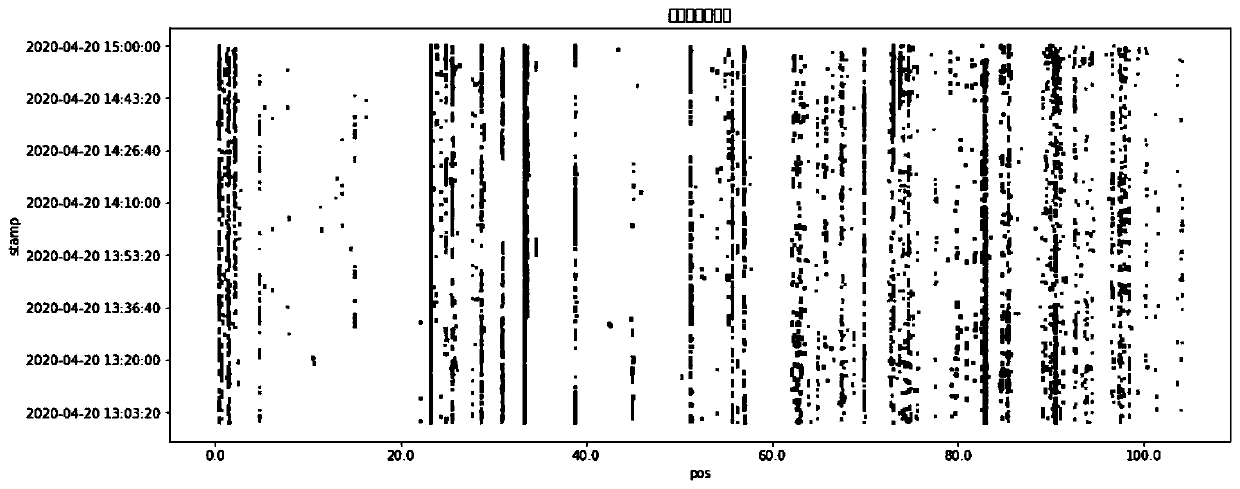

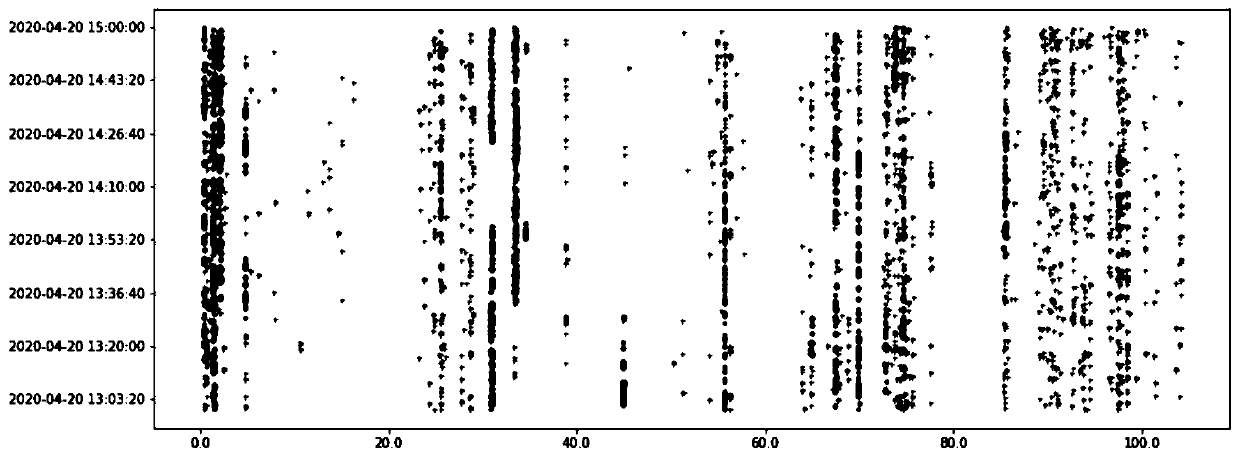

Real-time clustering early warning method for oil and gas pipeline monitoring based on massive vibration interference events

ActiveCN111578152AReduce the number of alarmsIn line with objective lawsSubsonic/sonic/ultrasonic wave measurementCharacter and pattern recognitionRayleigh scatteringPhotodetector

The invention provides a real-time clustering early warning method for oil and gas pipeline monitoring based on massive vibration interference events. In the method, a Rayleigh scattering-based coherent light time domain reflection vibration sensing system is included, and the method is characterized in that the Rayleigh scattering-based coherent light time domain reflection vibration sensing system comprises a laser, amplifiers, acousto-optic regulators, couplers, a digital signal processor, a driver, an isolator, a delay fiber, a piezoelectric ceramic driver, a photodetector, a central processing unit and a circulator. The A real-time clustering analysis method is adopted to perform cluster analysis on the vibration interference event data obtained through analysis in the time and spacedistribution dimensions at the same time, that is, the spatial distribution characteristics of abnormal interference events are considered, so as to better match the data characteristics caused by theinterference event behavior, which can significantly reduce the number of false positives, reduce the possibility of false negatives, and improve the accuracy and effectiveness of early warning.

Owner:ANHUI CASZT PHOTOELECTRIC MEASUREMENT & CONTROL TECH CO LTD

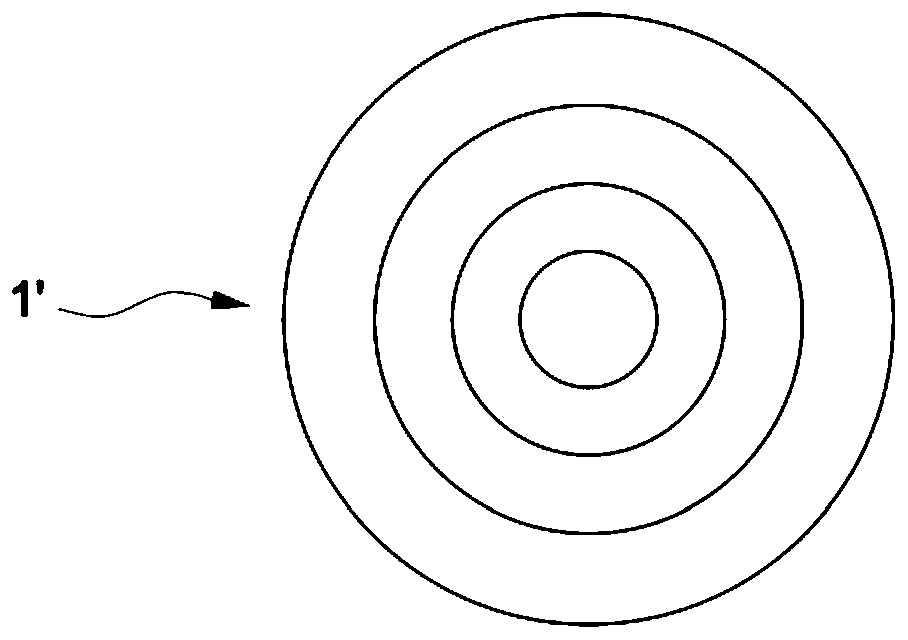

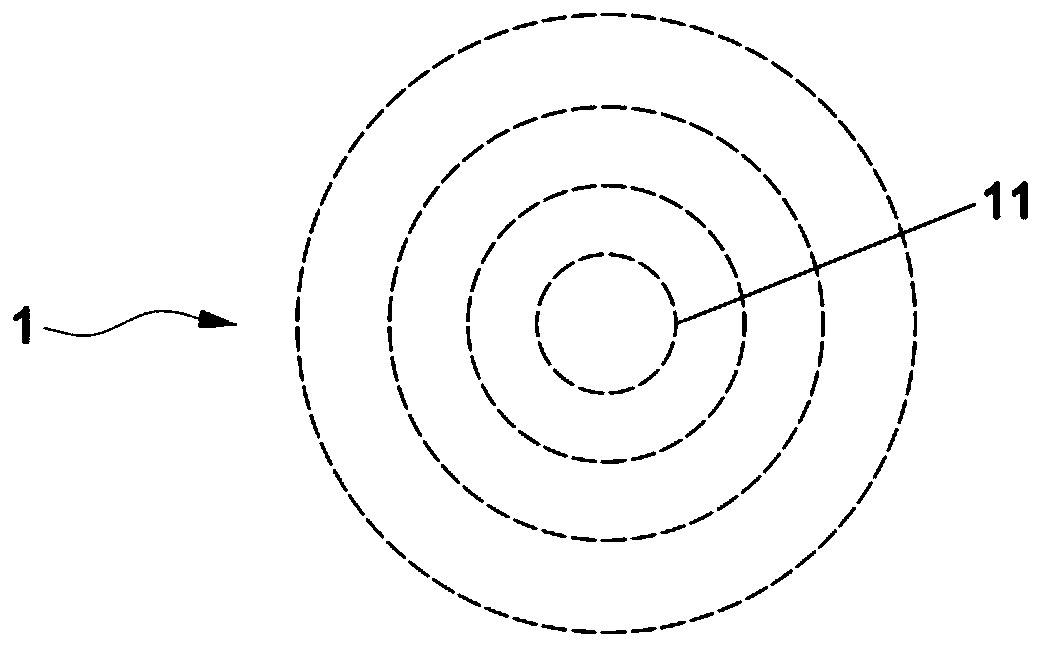

Mark dot pattern and preparation method thereof

InactiveCN111106199AEasy to identifyReduce the number of alarmsFinal product manufactureDuplicating/marking methodsEngineeringMechanical engineering

The invention belongs to the technical field of battery preparation, and discloses a Mark point pattern and a preparation method thereof. The Mark point pattern comprises a plurality of concentric circles. The outline of each circle is an imaginary line, and the imaginary and real parts of two circles adjacent to each other inside and outside are staggered and corresponding to each other. The preparation method comprises the steps of S1 drawing a base circle with a preset diameter at each of four corners of the surface of a battery piece by laser equipment according to preset coordinates; S2 performing concentric circle type filling or spiral line type filling from inside to outside on the basis of the base circle to obtain a Mark point base pattern; and S3 setting a virtual-real ratio, and selecting the Mark point basic pattern for laser marking to obtain the Mark point pattern. According to the invention, the overlapping marking phenomenon can be effectively reduced, so that the damage to the Mark point area is reduced; the Mark point pattern is easier to identify in the subsequent process; the alarm frequency is reduced; the marking time is shortened; and the productivity is improved.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

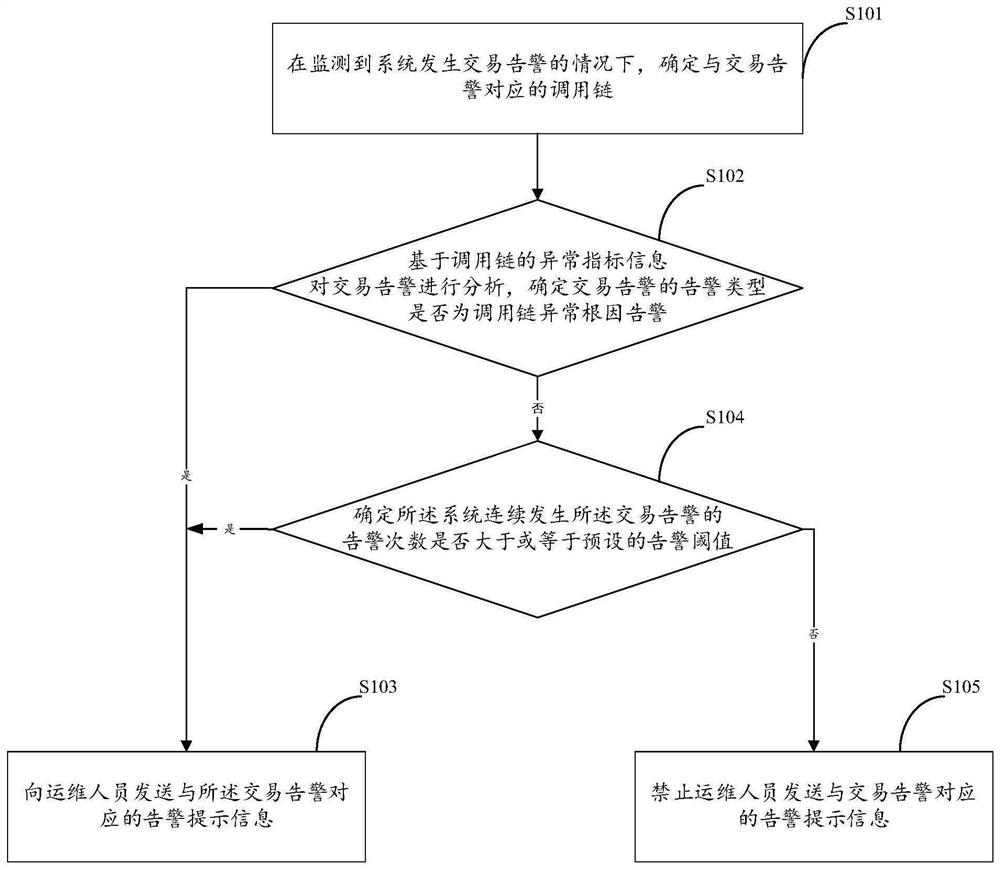

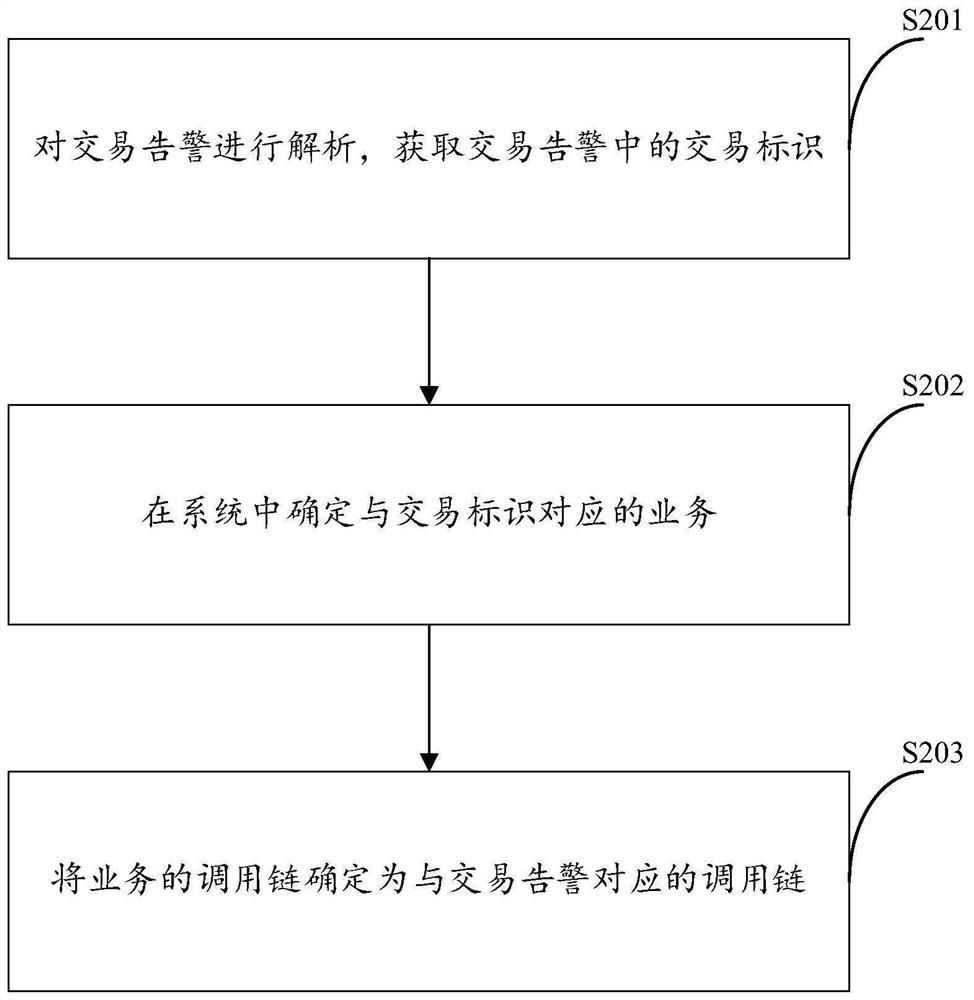

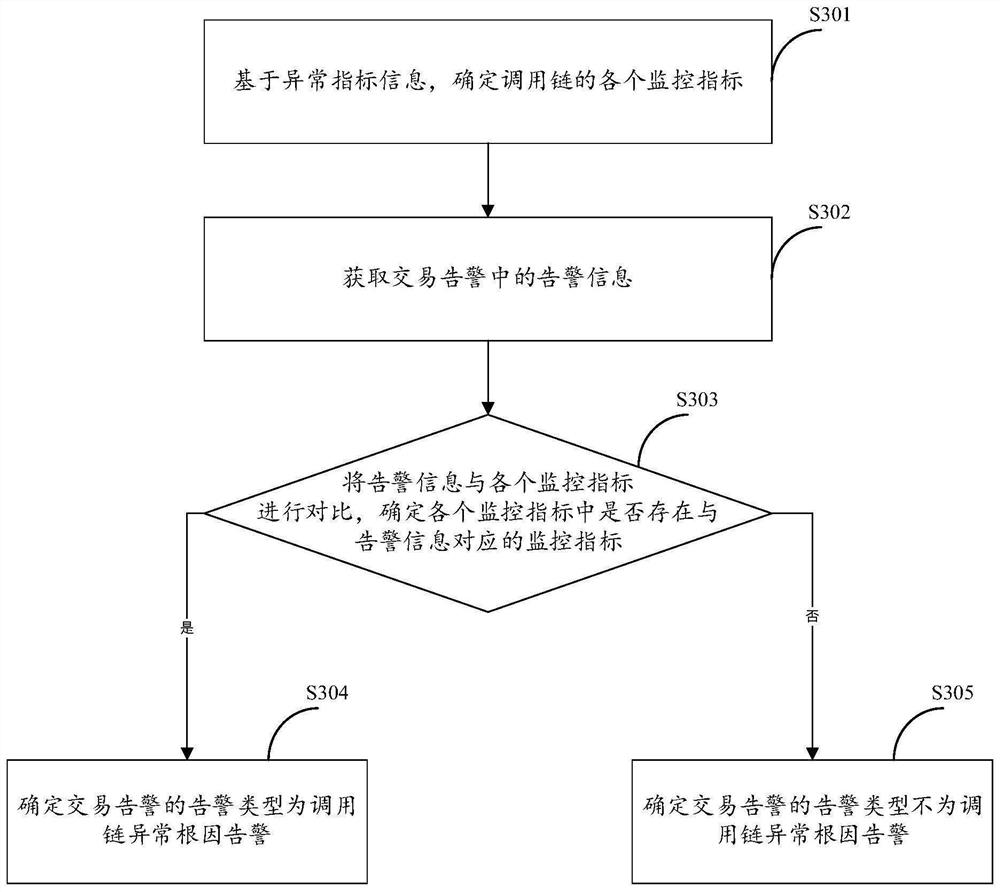

Alarm analysis method and device

PendingCN113821413AReduce workloadImprove work efficiencyHardware monitoringFinancial transactionAlarm analysis

The invention provides an alarm analysis method and device, and the method comprises the steps: determining a call chain corresponding to a transaction alarm under the condition that the transaction alarm of a system is monitored; analyzing the transaction alarm based on the abnormal index information of the call chain, and determining whether the alarm type of the transaction alarm is an abnormal root cause alarm of the call chain; if so, sending alarm information corresponding to the transaction alarm to operation and maintenance personnel; and if not, determining whether the alarm frequency that the system continuously generates transaction alarms is greater than or equal to an alarm threshold value, and if so, sending alarm information corresponding to the transaction alarms to operation and maintenance personnel. By analyzing the transaction alarms, when the alarm type of the transaction alarms is the preset alarm type or the alarm frequency of the transaction alarms continuously generated by the system is greater than or equal to the alarm threshold value, the alarm information is sent to the operation and maintenance personnel, so that the alarm frequency of the system is reduced, and the attention and workload of the operation and maintenance personnel to the system are reduced; and the working efficiency of operation and maintenance personnel is improved.

Owner:CHINA CONSTRUCTION BANK

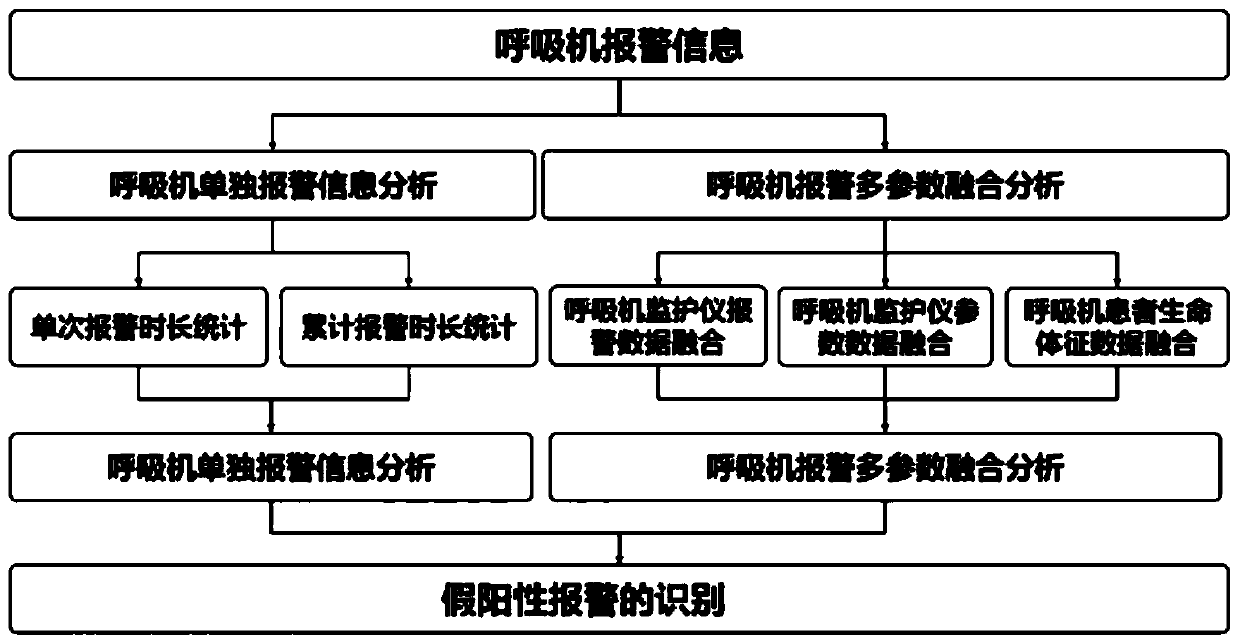

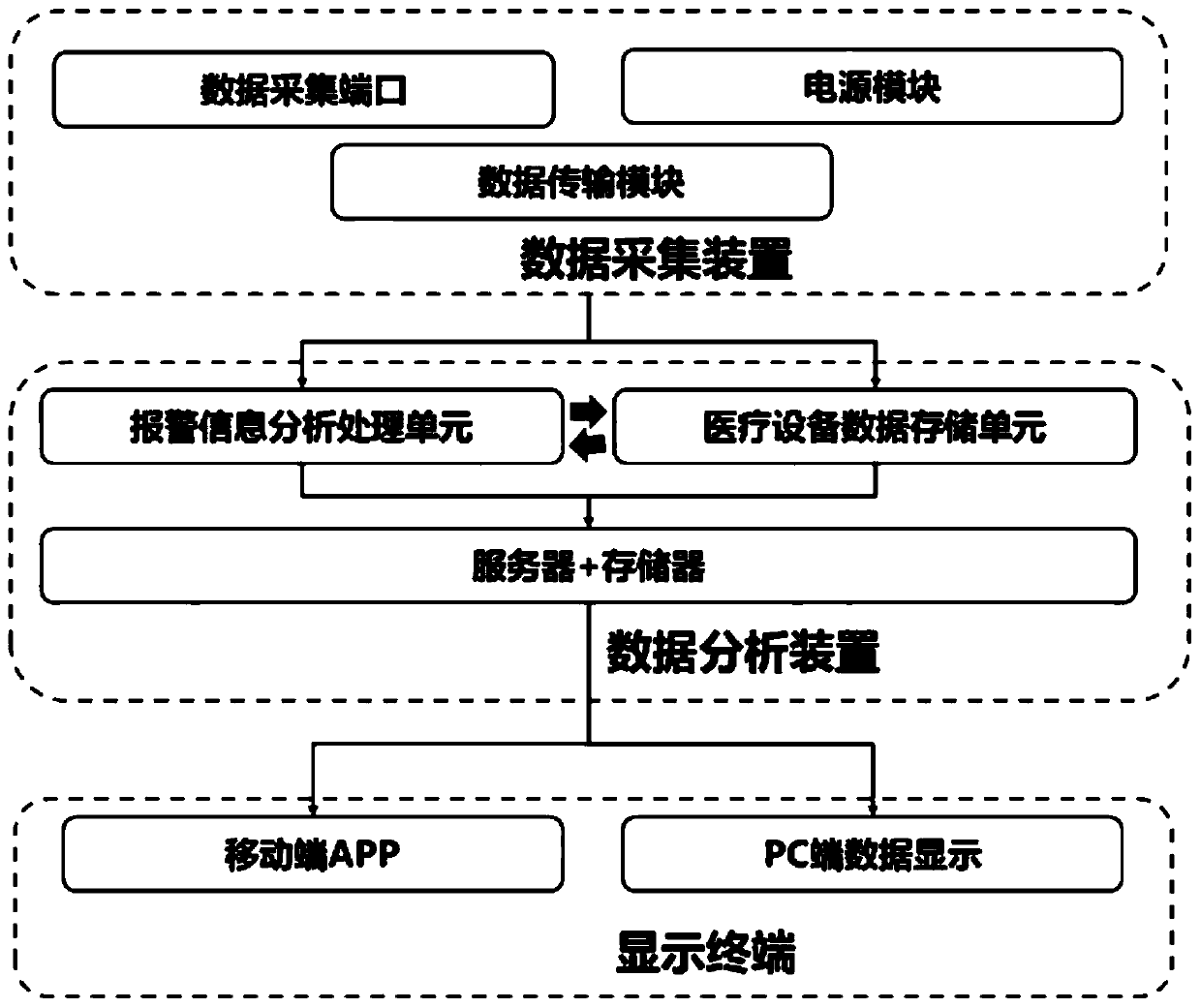

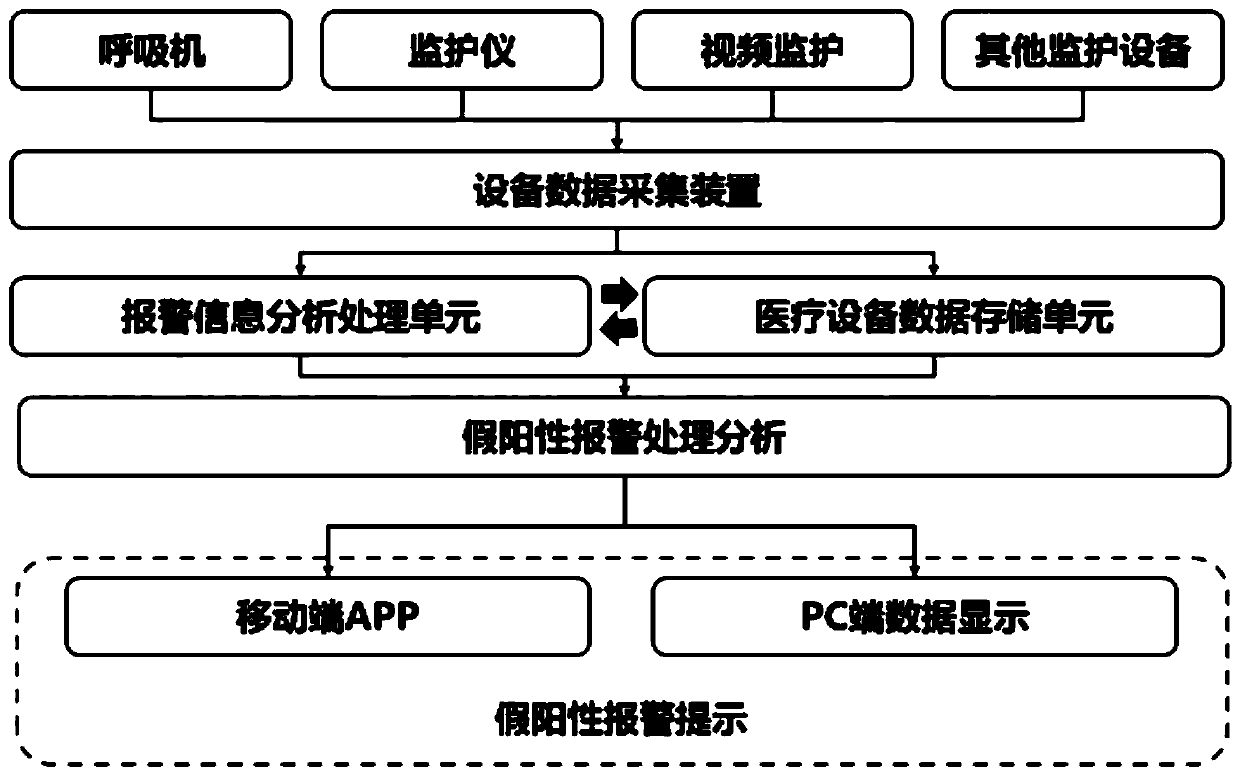

Breathing machine false positive alarm identification method and system

PendingCN111544720AReduce the number of alarmsReduce alarm fatigueRespiratorsMedical communicationEmergency medicineAlarm analysis

The invention relates to a breathing machine false positive alarm identification method and system. The breathing machine false positive alarm identification method comprises a false positive alarm analysis identification method based on breathing machine alarm data and a false positive alarm analysis identification method fusing the breathing machine alarm data and vital sign parameter information of a patient. According to the false positive alarm analysis and identification method based on the alarm data of the breathing machine, the alarm effectiveness of the breathing machine is analyzedand judged purely based on the alarm duration of the breathing machine, the false positive alarm analysis and identification method fusing the alarm data of the breathing machine and the vital sign parameter information of the patient comprises the step of comparing the alarm data of the breathing machine with the clinical vital sign parameters of the patient to judge the effectiveness of the alarm. The breathing machine alarm data can be analyzed, alarm effectiveness can be recognized and analyzed, false positive alarms are reduced, and alarm fatigue of medical staff is reduced.

Owner:CHINA JAPAN FRIENDSHIP HOSPITAL

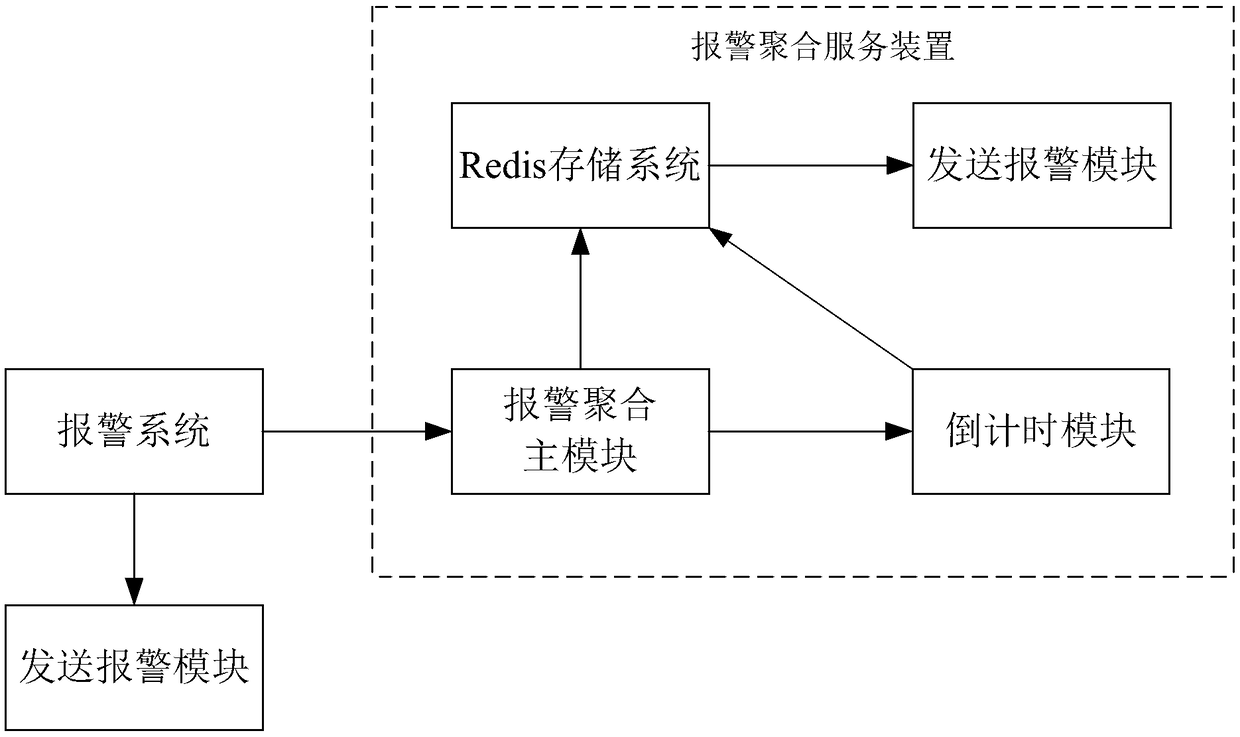

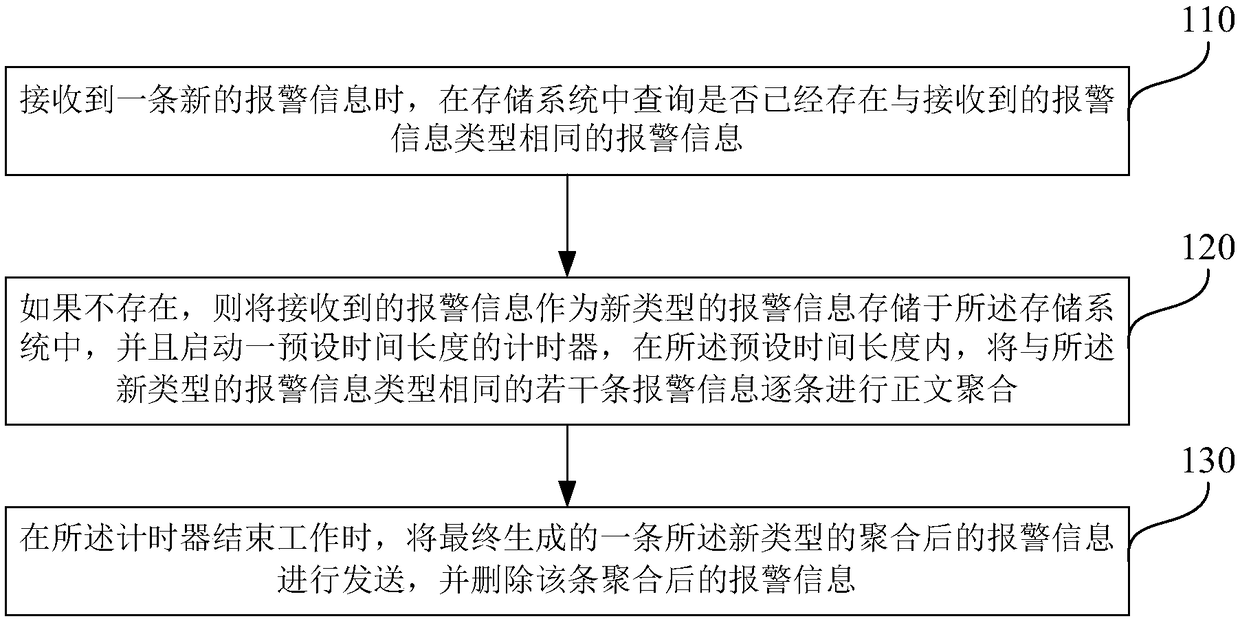

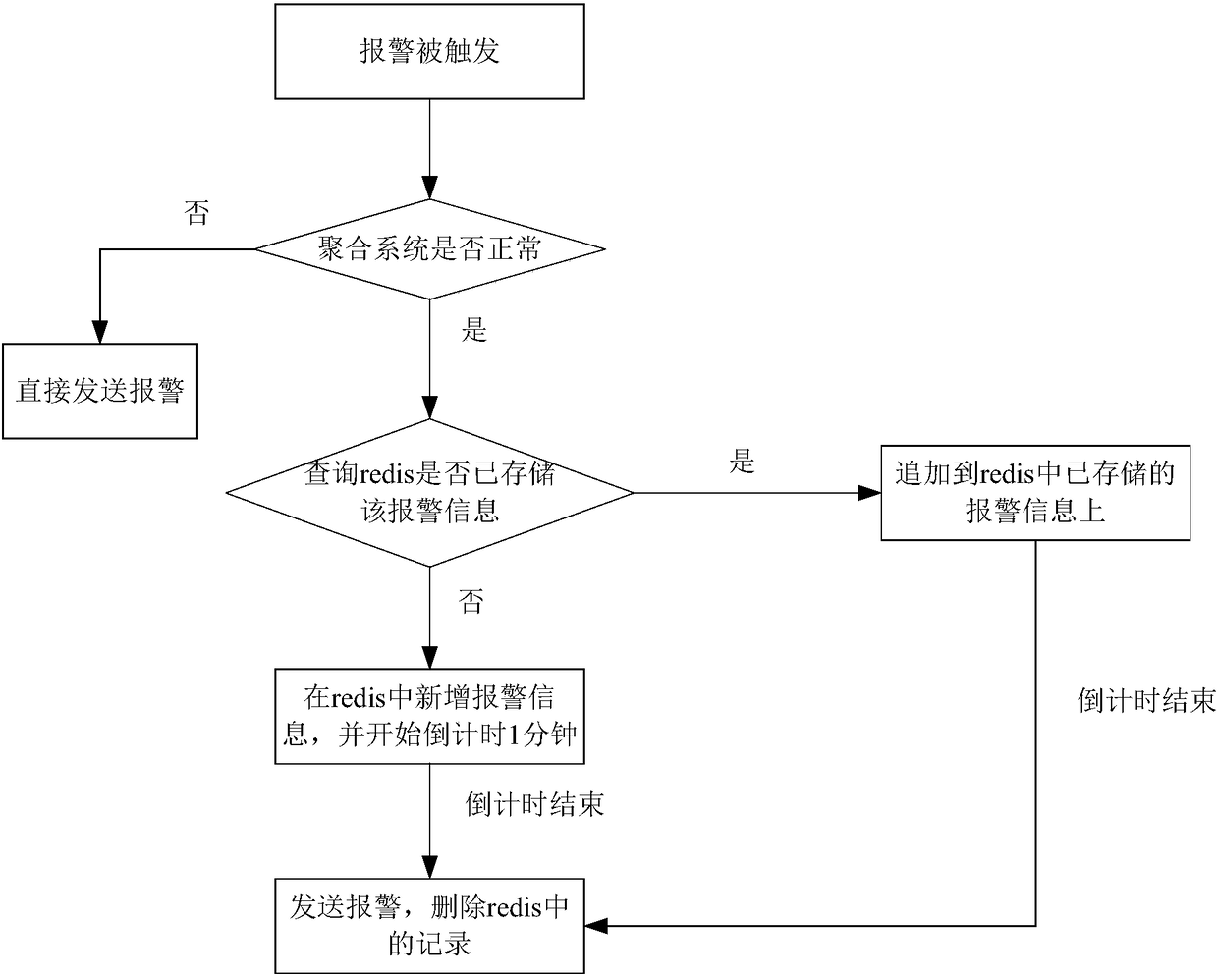

Business alert aggregation method and apparatus

Embodiments of the invention provide a business alert aggregation method and apparatus. The method comprises the steps of querying whether alert information with the same type as received alert information exists or not in a storage system when a piece of the new alert information is received; if the alert information with the same type as the received alert information does not exist, storing thereceived alert information as a new type of alert information in the storage system, starting a timer with a preset time length, and in the preset time length, performing text aggregation on the multiple pieces of the alert information with the same type as the new type of the alert information one by one; and when the timer stops working, sending the new type of the finally generated aggregatedalert information, and deleting the aggregated alert information. Through alert prejudgment, alert waiting and alert aggregation, the same alerts in a certain time are aggregated, so that the alert quantity is reduced, the alert quality is improved, and the pressure of an alert platform is reduced.

Owner:MICRO DREAM TECHTRONIC NETWORK TECH CHINACO

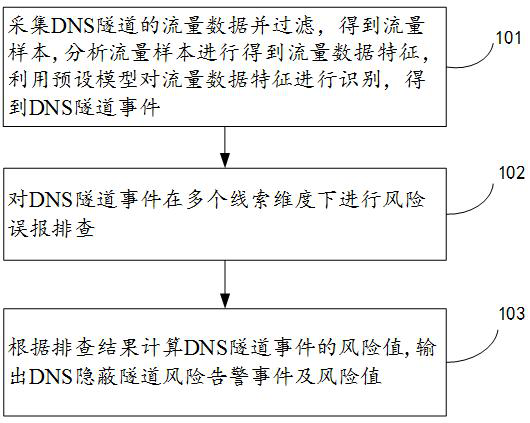

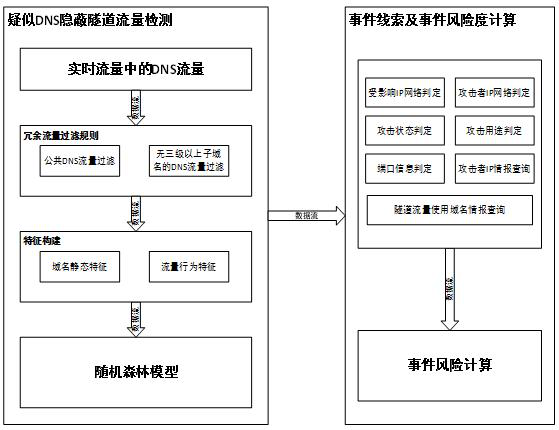

DNS hidden tunnel event automatic detection method and device, and electronic equipment

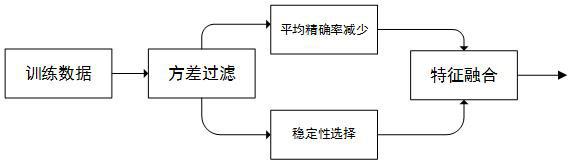

ActiveCN112822223AStochastic quantitative precisionRich event troubleshooting cluesTransmissionData miningFalse alarm

The invention discloses a DNS hidden tunnel event automatic detection method and device, and electronic equipment. The method comprises the steps: collecting flow data of a DNS tunnel, filtering the redundant flow data, and obtaining a flow sample; analyzing the traffic sample, and extracting traffic data features; identifying the extracted flow data features by using a preset model to obtain a DNS tunnel event; carrying out risk false alarm troubleshooting on the DNS tunnel event under a plurality of clue dimensions; calculating a risk value of the DNS tunnel event according to a troubleshooting result; and outputting the DNS hidden tunnel risk event alarm and the risk value. According to the scheme, various event troubleshooting clues are provided for safety analysts, the false alarm rate is reduced, and the interface friendliness is improved.

Owner:天际友盟(珠海)科技有限公司

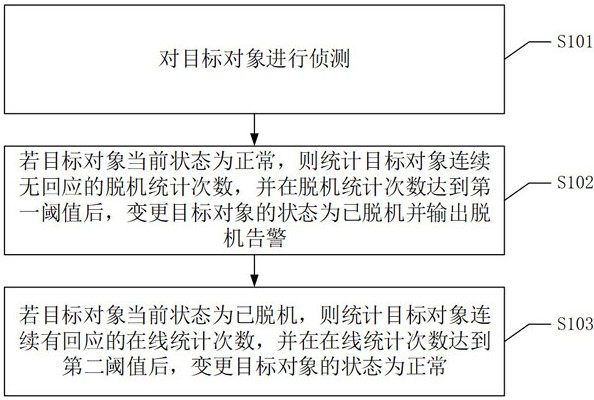

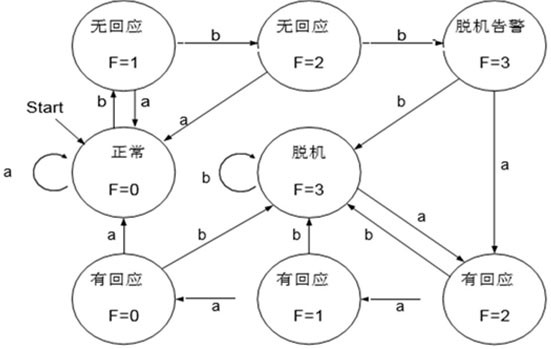

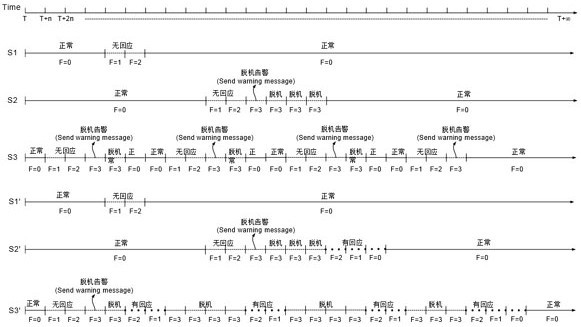

Disconnection return detection method and device, equipment and readable storage medium

InactiveCN113518020AReduce distractionsReduce false alarmsData switching networksComputer scienceFalse alarm

Owner:INSPUR SUZHOU INTELLIGENT TECH CO LTD

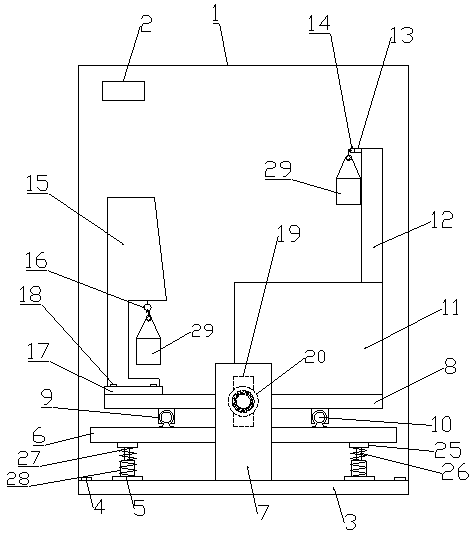

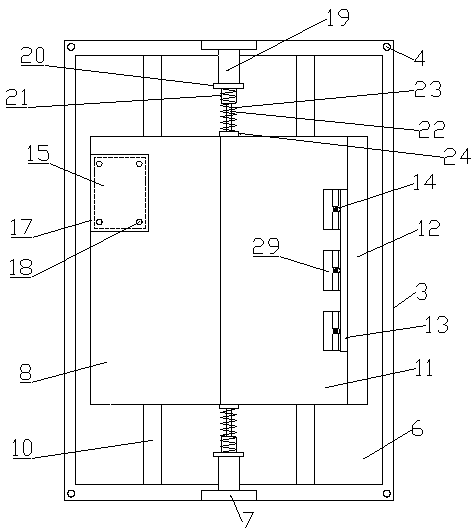

Intelligent automatic gas cut-off valve control system and control method thereof

InactiveCN110517456AShorten the timeTimely responseOperating means/releasing devices for valvesAlarmsControl systemComputer module

The invention discloses an intelligent automatic fuel gas cut-off valve control system and a control method thereof, and relates to the technical field of valve control. The system is characterized bycomprising a detection module used for sending out a leakage signal after fuel gas leakage is detected; an alarm module electrically connected to the output end of the detection module and is used for giving an alarm after receiving the leakage signal; and an execution module used for cutting off the valve after receiving the leakage signal and including a circuit breaker relay connected to the output end of the detection module. A normally-closed contact of the circuit breaker relay is connected with the valve in series. The alarm module comprises a remote alarm unit in signal connection with the detection module, the remote alarm unit gives an alarm remotely after receiving the leakage signal, and the remote alarm unit further comprises a control button used for controlling the valve tobe closed. The technical problem that danger is easily caused by gas leakage is solved, and the device has the advantage that the danger caused by gas leakage is reduced.

Owner:深圳市中燃科技有限公司

Mobile continuous blood purification emergency system and using method thereof

InactiveCN109771719AMedical Difficulties Achieving TransshipmentGuaranteed uptimeNon-rotating vibration suppressionDialysis systemsEngineeringBlood purification

The invention relates to a mobile continuous blood purification emergency system and a using method thereof. The upper portion of a bottom plate is provided with a damping energy consumption balancingdevice, a continuous blood purification machine with a weight measuring hook is fixedly installed above the damping energy consumption balancing device, a bearing bed body is fixedly installed at oneside of the continuous blood purification machine, and at least two balance suspension devices matched with the weight measuring hook are movably installed at the top of the bearing bed body; each balance suspension device comprises a fixing hook matched with the weight measuring hook, the bottom of each fixing hook is connected with a fixing shaft, two rotating cylinders symmetrically sleeve thefixing shafts at the two sides of the fixing hooks, each rotating cylinder is provided with a suspension groove, each suspension groove sleeves a hanging rope, and a bearing container is connected tothe bottom of each hanging rope. The defect that existing hemodialysis equipment cannot run normally in a movement, shaking, swinging and vibration environment is overcome.

Owner:THE FIRST AFFILIATED HOSPITAL OF ZHENGZHOU UNIV

Statistical method of safety supervision system alarm numbers

The statistical method of safety supervision system alarm numbers comprises the following steps of step1, setting a time limit value; step2, when a value measured at one moment exceeds a threshold, recording the moment, and in a time period from the moment to the later time limit value, calculating the total time period sum of the values which exceed the threshold through real-time measurement; and step3, setting a percentage, calculating the ratio of the total time period and the time limit value in the step two, when the ratio exceeds the percentage, considering that the value in the time period is abnormal and calculating as one alarm number; otherwise, carrying out the operation that the number is not counted. In the invention, repeated statistical alarm numbers can be greatly reducedand the validity of the alarm numbers is increased.

Owner:ZHEJIANG UNIV OF TECH

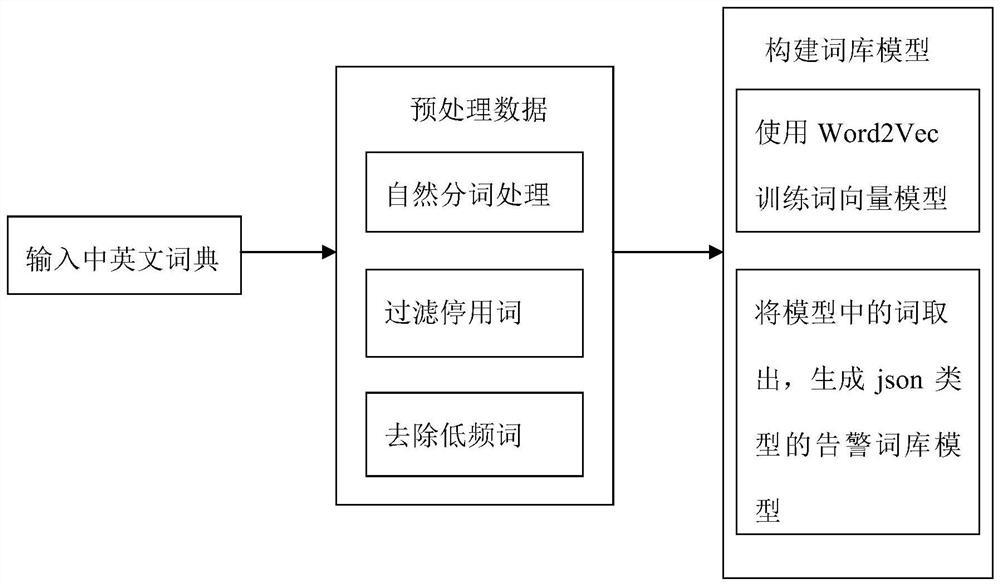

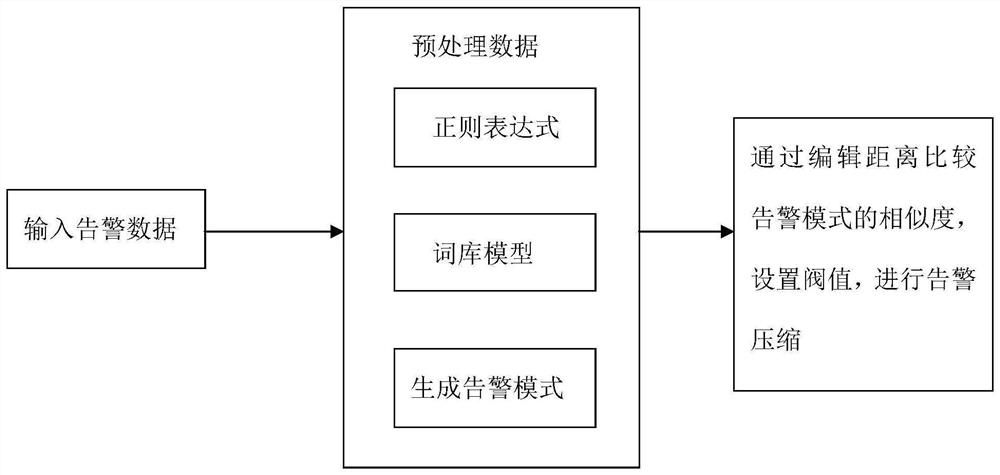

Method for extracting effective alarm data based on natural language features

PendingCN112784592AReduce the number of alarmsImprove work efficiencyNatural language data processingSpecial data processing applicationsNatural languageDimensionality reduction

The invention discloses a method for extracting effective alarm data based on natural language features, which comprises a locality sensitive hash module and an editing distance algorithm module, and is characterized in that the locality sensitive hash algorithm module comprises a word segmentation module, a hash module, a weighting module, a merging module and a dimension reduction module; the word segmentation module is used for giving a section of statement, carrying out word segmentation to obtain effective feature vectors, and then setting weights of 5 levels such as 1-5 for each feature vector; the hash module calculates a hash value of each feature vector through a hash function; the weighting module is used for weighting all the feature vectors on the basis of the hash value; the merging module accumulates weighting results of the feature vectors to form only one sequence string; the dimension reduction module is used for obtaining a simhash value of a statement; and the editing distance algorithm module performs similarity clustering on the hash values.

Owner:四川睿象科技有限公司

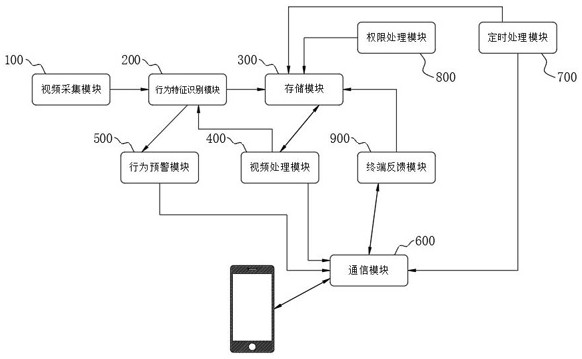

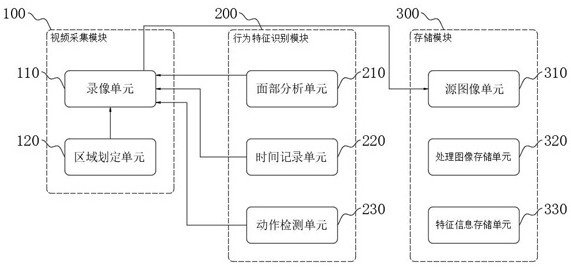

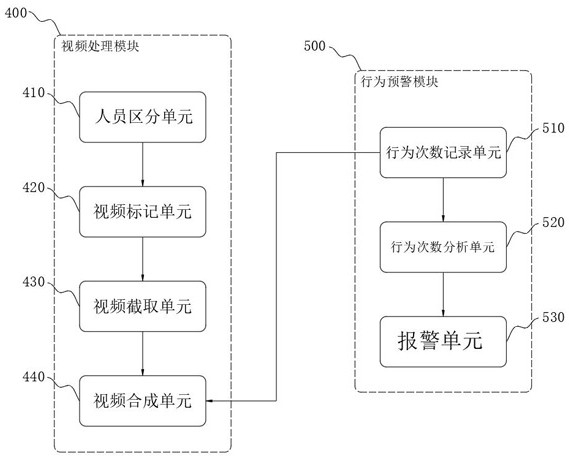

Bicycle sales alarm system capable of detecting and analyzing human behaviors

PendingCN114565980AReduce the number of alarmsHigh efficiencyVideo data browsing/visualisationBurglar alarmEmbedded systemReal-time computing

The invention relates to an alarm system, in particular to a bicycle sales alarm system capable of detecting and analyzing human behaviors. The system comprises a communication module, a video acquisition module, a behavior feature recognition module, a storage module, a video processing module and a behavior early warning module, and the communication module connects an alarm system with a terminal device and transmits instructions and data between the alarm system and the terminal device; according to the bicycle sales alarm system capable of detecting and analyzing the human body behaviors, related pictures of videos are intercepted according to the actions of people to obtain action videos, the action videos are synthesized, then the amplitude and the number of times of the actions are judged to select whether to give an alarm or not, the number of times of the alarm is reduced, and the alarm efficiency is improved. And the alarm efficiency is improved.

Owner:广州市普丰科技有限公司

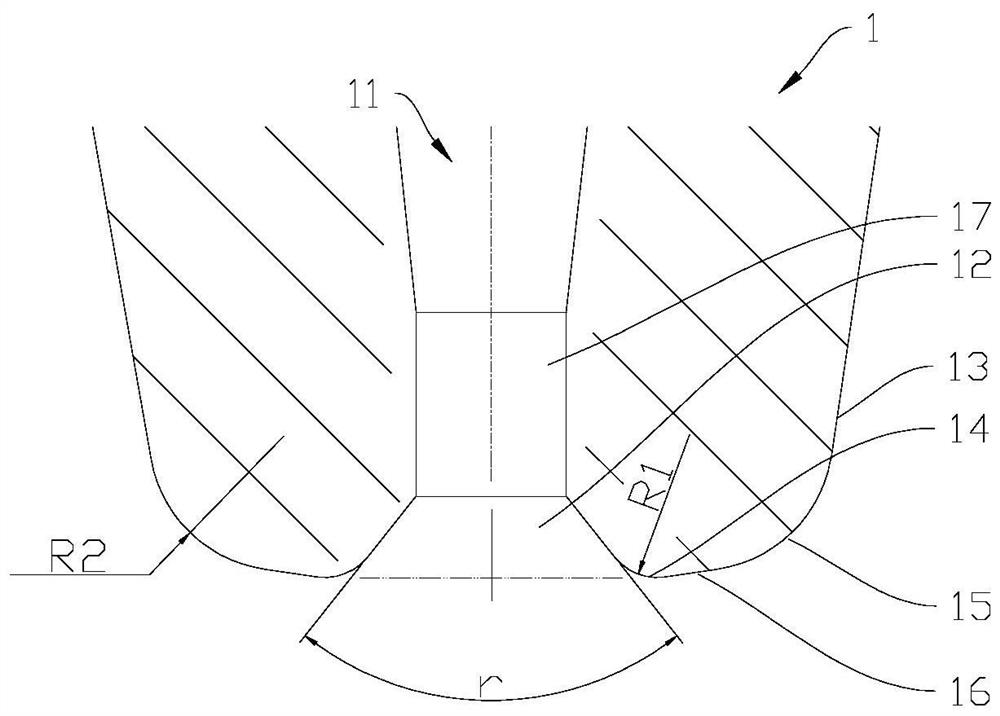

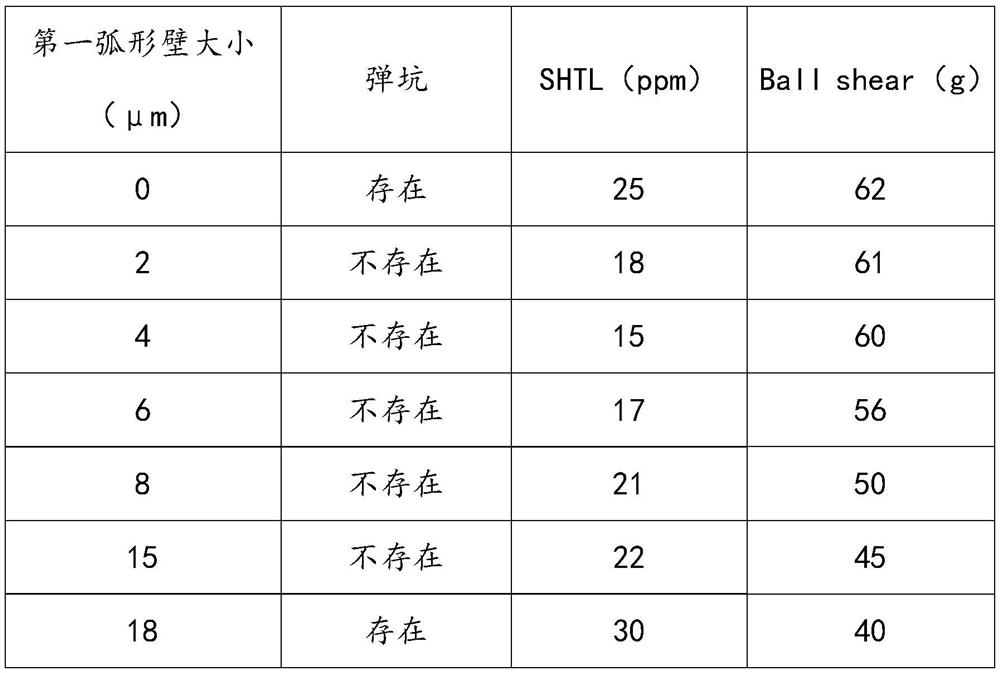

Welding chopper and welding equipment

The invention discloses a welding chopper and welding equipment. The welding chopper is provided with a wire passing through hole, the wire passing through hole extends to the end of the welding chopper, the position, close to the end of the welding chopper, of the wire passing through hole is provided with a conical inner wall surface expanding outwards, and the conical inner wall surface is connected with the outer wall surface of the welding chopper through arc-shaped wall surfaces; the arc-shaped wall surfaces comprise a first arc-shaped wall surface and a second arc-shaped wall surface, the first arc-shaped wall surface is closer to the end of the welding chopper relative to the second arc-shaped wall surface, the first arc-shaped wall surface is in transition connection with the outer wall surface of the welding chopper through the second arc-shaped wall surface, and the second arc-shaped wall surface is in transition connection with the conical inner wall surface through the first arc-shaped wall surface; and the radius of the first arc-shaped wall surface is R1, and R1 is larger than 0 and smaller than or equal to 15 micrometers. According to the welding chopper and the welding equipment, the concentration ratio, to the stress of a welding ball, of the welding chopper can be reduced, craters, caused by stress concentration, of a chip bonding pad are reduced, the concentration of tangent line tail force when a second welding spot is welded is reduced, and the occurrence of line tail breakage in the rising process of the chopper is reduced.

Owner:苏州三环科技有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com