System and method for eliminating crystals of selective catalytic reduction system

A selective and crystallization technology, applied in the control equipment for eliminating the crystallization of the selective catalytic reduction system, eliminating the crystallization of the selective catalytic reduction system, and the field of computer-readable storage media, can solve the problems such as crystallization monitoring cannot be realized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

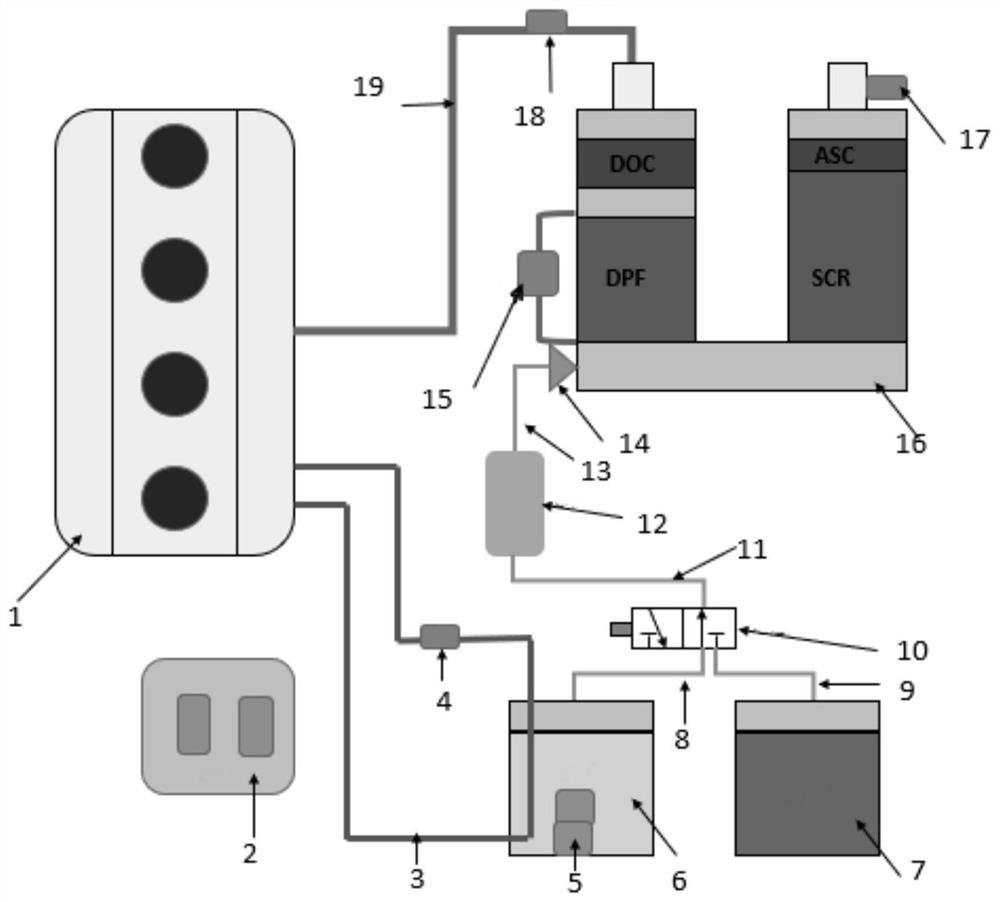

[0084] A system for eliminating engine SCR post-treatment crystallization, including engine 1, ECM 2, coolant pipeline 3, electromagnetic switch 4, temperature-liquid level sensor 5, water tank 6 (the liquid is water), urea tank 7 (the Said solution is urea), water suction pipe 8 (the second suction pipe), liquid suction pipe 9 (the first suction pipe), two-position three-way solenoid valve 10, liquid transmission pipe 11 (the transmission pipe ), urea pump 12 (the pump), injection line 13, nozzle 14 (the injection device includes injection line and nozzle), DPF differential pressure and pressure sensor 15, SCR aftertreatment 16 (the selective catalytic reduction system) , outlet NOX sensor 17, inlet NOX sensor 18 and exhaust tailpipe 19.

[0085] Wherein, the inlet NOX sensor 18 is installed on the exhaust tailpipe 19 for measuring the original NOX of the engine, one end of the exhaust tailpipe 19 is connected to the engine 1, and the other end is connected to the SCR post-pr...

Embodiment 2

[0096] Based on Embodiment 1, under the normal working mode (the normal working state), the urea solution in the urea tank 7 passes through the suction pipe 9, the two-position three-way solenoid valve 10, the liquid transfer pipe 11, and the urea solution under the control of the ECM2. The pump 12, injection line 13, and nozzle 14 enter the SCR post-treatment 16 to react with NOX;

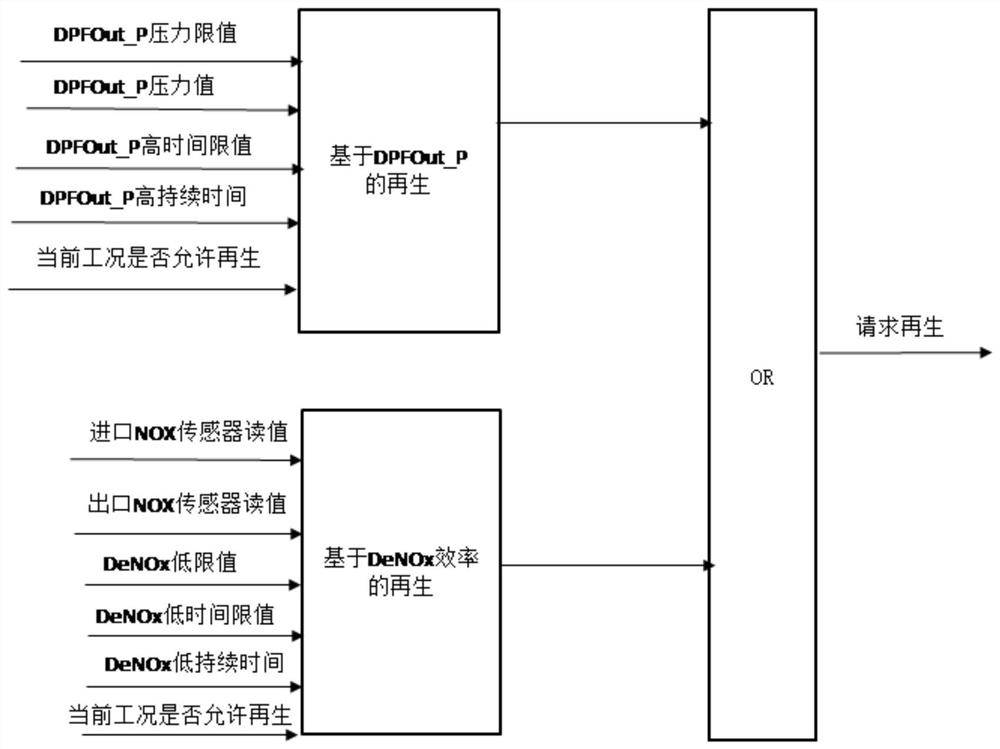

[0097] Wherein, when there is crystallization in the SCR post-processing 16 detected by the DPF differential pressure and pressure sensor 15, the outlet NOX sensor 17, and the inlet NOX sensor 18, switch to the temporary working state, the nozzle 14 is opened, and the ECM2 controls the urea pump 12 to execute Reverse, the remaining urea in the nozzle 14 returns to the urea tank 7 through the injection line 13, the urea pump 12, the liquid transfer pipe 11, the two-position three-way solenoid valve 10, and the suction pipe 9, that is, the residual urea back-absorption process, NOX-related OBD diagn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com