Bonded bleed-out judging and alarming method

A technology of breakout and judgment procedure, which is applied in the field of continuous casting technology, can solve problems such as the increase in the number of low-quality slabs, the decline in the internal quality of slabs, and the decrease in the constant speed of continuous casting machines, so as to improve the accuracy rate and increase the cost of continuous casting. Billet rate, avoiding the effect of continuous casting machine constant rate reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The slab of ultra-low carbon steel with a section of 1550mm is produced on the slab continuous casting machine. The crystallizer monitoring system is set up in three rows with 18 monitoring thermocouples in each row.

[0025] When the third tank was poured for 10 minutes, the crystallizer temperature monitoring screen showed that the temperature curve detected by the first row of thermocouples rose and then fell, and the temperature curves detected by the middle row and the third row of thermocouples rose after a period of time and then fell, and The temperature curves of the upper and lower rows intersect. At this time, the temperature curves detected by the same row of thermocouples on both sides do not conform to the set alarm temperature curve mode, so it is automatically judged that there is a bonding breakout phenomenon, and no alarm is given. After the slab came off the production line, no sticking traces were found after inspection, indicating that the judgment ...

Embodiment 2

[0027] Slabs of common carbon steel with a section of 1500mm are produced on the slab continuous casting machine. The crystallizer monitoring system is set up in three rows with 18 monitoring thermocouples in each row.

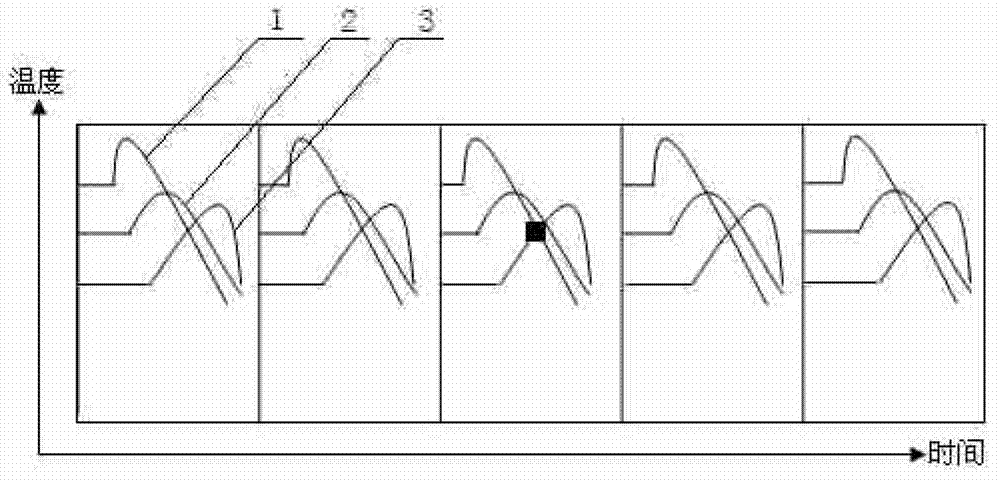

[0028] When pouring the fourth tank, the temperature curve 1 detected by the seventh thermocouple in the first row displayed on the crystallizer temperature monitoring screen rises and then falls, and the temperature curve 2 detected by the middle row of thermocouples is the same as that detected by the third row of thermocouples. The temperature curve of temperature 3 lags behind for a period of time and then rises and then falls, and with the 7th thermocouple as the center, the 6th, 5th, 4th and 8th, 9th, and 10th thermocouples on both sides of the same row appear symmetrically. The curve is similar to the temperature curve of the seventh thermocouple in the first row, but the response time lags successively, and the three rows of temperature curves displaye...

Embodiment 3

[0031] The slab of ultra-low carbon steel with a section of 1550mm is produced on the slab continuous casting machine. The crystallizer monitoring system is set up in three rows with 18 monitoring thermocouples in each row.

[0032] During the process of pouring the third tank, the crystallizer temperature monitoring screen shows that the temperature curve 1 detected by the first thermocouple in the middle row rises and then falls, and the temperature curves detected by the first thermocouple in the first row and the third row both lag After a period of time, there is a phenomenon of rising and then falling, and the temperature curves of the 2nd, 3rd, and 4th thermocouples in the three rows are similar to the temperature curves of the first thermocouple in the middle row, but the response time lags behind each other, and the temperature of the three rows The curves intersect, so it is determined that the phenomenon of bonded breakout occurs and an alarm is given. The continuo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com