A method to match the low-speed pouring of extra-thick slab and the consumption of mold flux in continuous casting

A technology for continuous casting mold flux and extra-thick slab, which is applied in the field of continuous casting mold flux for steelmaking and continuous casting molds, and can solve the problems of micro-cracks in the billet shell, slag film falling off, and poor fluidity of continuous casting mold flux.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

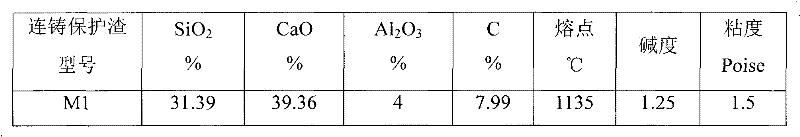

[0007] For medium carbon steel D36-1 (carbon content 0.16%) with a thickness of 400mm, the special continuous casting mold powder M1 is determined, as shown in Table 1; at the same time, the vibration mode 6 is selected. When the casting speed is 0.7m / min, the vibration frequency is 153cpm, amplitude 4.8mm, negative slip time 0.10s, continuous casting mold flux consumption 0.57kg / m 2 , The measured liquid slag layer thickness is 9-11mm, and the melting and consumption of continuous casting mold slag have reached a good balance.

[0008] Table 1 Physical and chemical performance indicators of continuous casting mold slag

[0009]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com