Flavoring device for processing sauce braised meat products

A technology of stewed meat products and workbench, which is applied in the direction of meat processing, application, meat tenderization, etc., can solve the problems of poor safety and low efficiency, and achieve the effect of uniform force, high safety, simple and ingenious and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

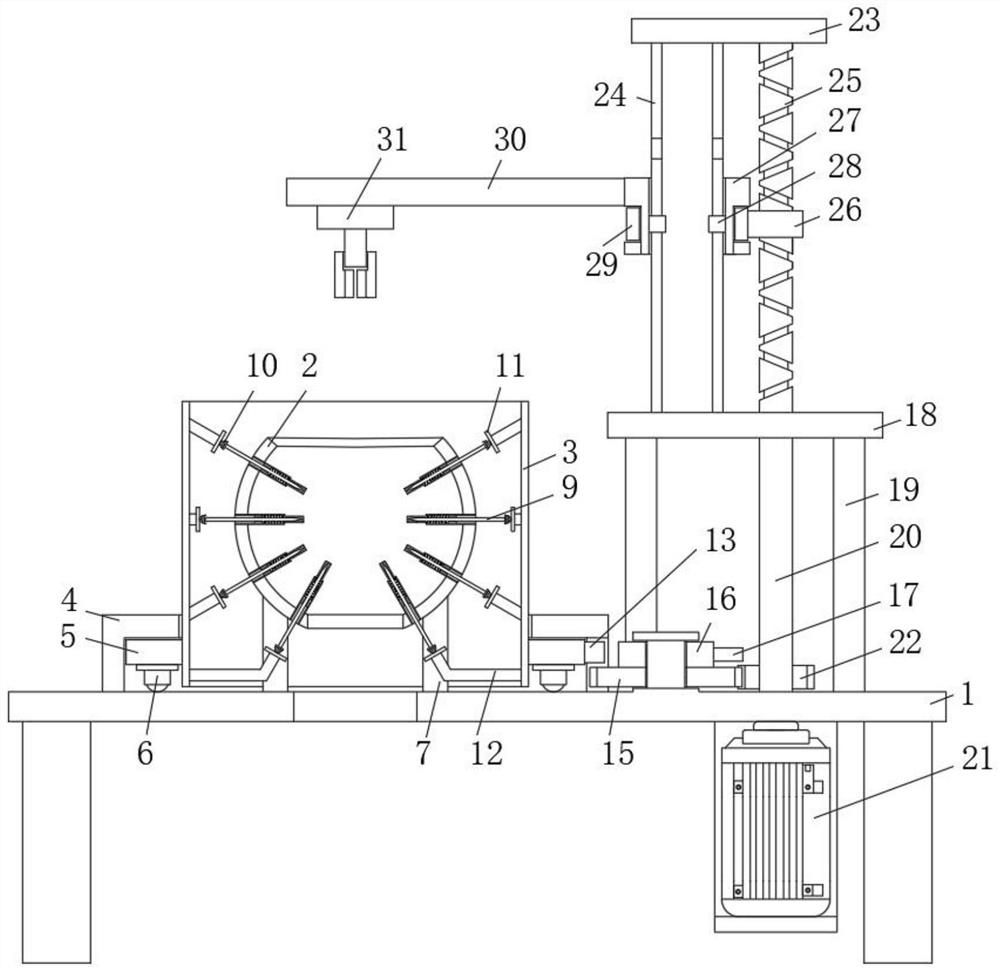

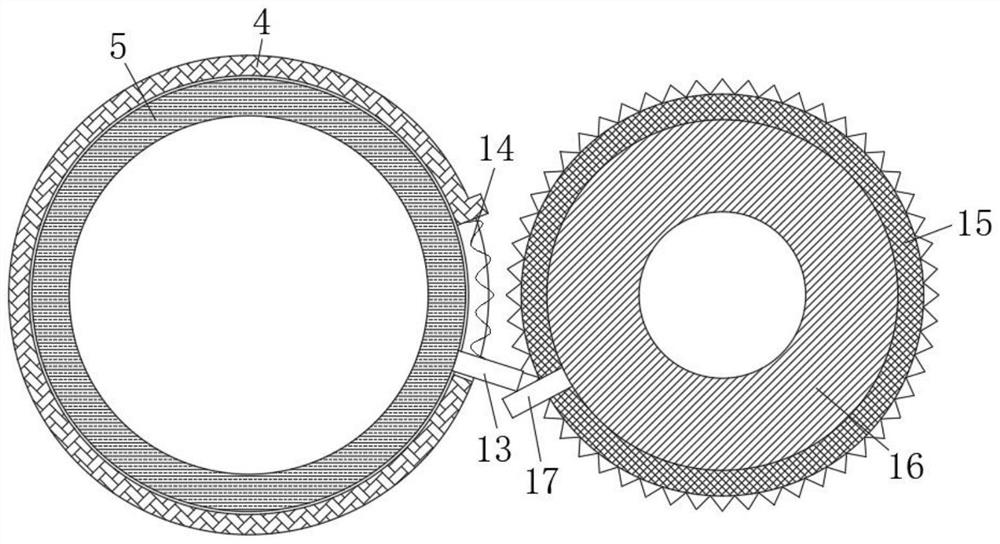

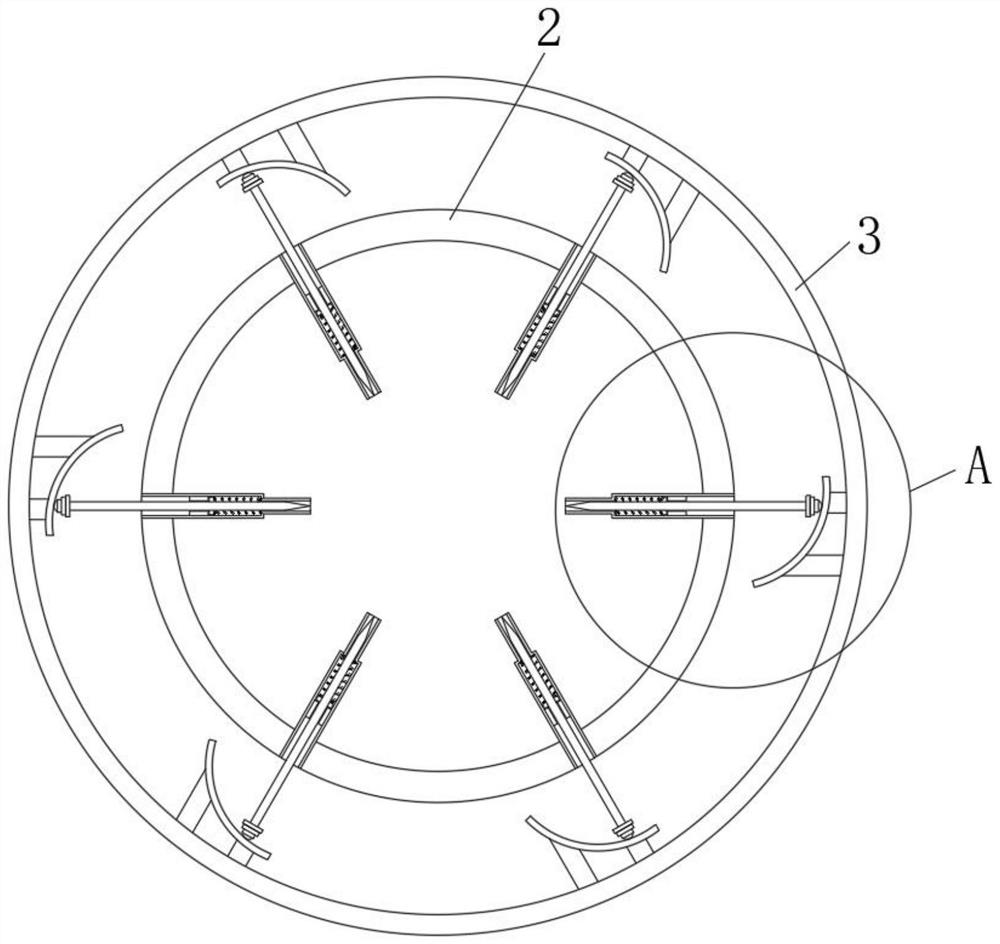

[0028] refer to Figure 1-4 , a flavoring device for processing braised meat products, comprising a workbench 1, a top side fixing frame of the workbench 1 is provided with an inner bulb 2, a support column 7 is fixed between the inner bulb 2 and the workbench 1, and the inner bulb The outer rotating sleeve of 2 is provided with a peripheral cover 3, the top and bottom of the inner bladder 2 are both open-type structures, and the bladder body of the inner bladder 2 is spherically divergent and fixedly connected with a number of outer cylinders 8. There is an elastic retractable needle 9, the tip of the elastic retractable needle 9 can extend into the inner bladder 2, the other end of the elastic retractable needle 9 is installed with a contact ball 10, and one side of the elastic retractable needle 9 is provided with an arc-shaped sliding push plate 11. The contact ball 10 is connected in rolling contact with one side of the arc-shaped sliding plate 11. An inner strut 12 is fi...

Embodiment 2

[0035] like Figure 1-4As shown, this embodiment is basically the same as Embodiment 1. Preferably, the combined drive mechanism includes a stand 18 vertically above the workbench 1, and a support frame 19 is fixedly framed between the stand 18 and the workbench 1, and is also rotatably installed at the same time. There is a rotating shaft 20, a servo motor 21 is fixedly installed on the bottom side of the worktable 1 by bolts, the bottom end of the rotating shaft 20 is fixedly driven by the output shaft of the servo motor 21, and the outer side of the shaft body of the rotating shaft 20 is fixedly sleeved with a driving gear ring 22, which is driven by One side of the gear ring 22 is meshed with the driven gear ring 15 , and the driven gear ring 15 is coaxially fixed with the coaxial ring 16 .

[0036] In this embodiment, the output shaft of the servo motor 21 drives the rotating shaft 20 to rotate, and the driving gear ring 22 coaxially fixed on the outside of the shaft body...

Embodiment 3

[0038] like Figure 1-4 As shown, this embodiment is basically the same as Embodiment 1. Preferably, a top plate 23 is provided vertically above the stand 18, and a rail vertical cylinder 24 is fixedly connected between the bottom side of the top plate 23 and the stand 18, and a reciprocating wire is rotatably installed. screw 25, the bottom end of the reciprocating screw 25 is coaxially fixed with the top end of the rotating shaft 20, the outer side of the reciprocating screw 25 is equipped with a screw nut 26, the outer rotating sleeve of the rail vertical cylinder 24 is provided with a rotating sleeve 27, and the rail vertical cylinder is provided with a rotating sleeve 27. The cylinder wall of 24 is provided with a track hole and is slidably connected with a sliding core 28. One end of the sliding core 28 is fixed to the inner wall of the rotating sleeve 27. The vertical outer side of the rotating sleeve 27 is provided with a ring groove, and a lifting ring 29 is rotatably ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com